YoLong Breweries Are Off to BrewCon19 in Melbourne this September

For those of you who make a point of following the YoLong Brewtech…

What do most commercial breweries/microbreweries do for sanitization?

Most of the brewers use their own methods and follow their own…

https://yolongbrewtech.com/wp-content/uploads/2018/12/PLC_Brewhouse-cabinet.jpg

951

1617

manage1

https://yolongbrewtech.com/wp-content/uploads/2022/08/YoLong-Brewtech-Logo-1-300x113.png

manage12019-08-24 01:43:552023-04-24 00:59:50What’s the best home beer brewing kit

https://yolongbrewtech.com/wp-content/uploads/2018/12/PLC_Brewhouse-cabinet.jpg

951

1617

manage1

https://yolongbrewtech.com/wp-content/uploads/2022/08/YoLong-Brewtech-Logo-1-300x113.png

manage12019-08-24 01:43:552023-04-24 00:59:50What’s the best home beer brewing kit

What are the possible hazards that can occur in a brewery, and how can you mitigate them

Most of the people have got involved in the craft brewery with…

Which Beer Is Good For Health

Overview of Beer and Its Health Benefits

Beer has been enjoyed…

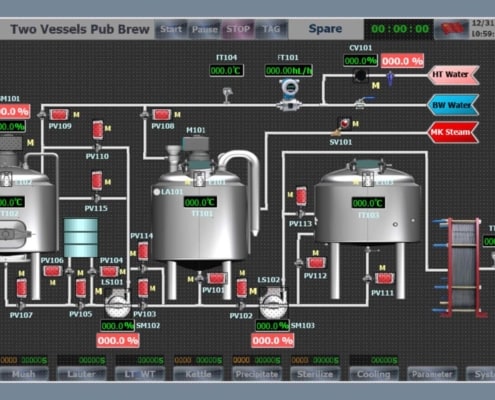

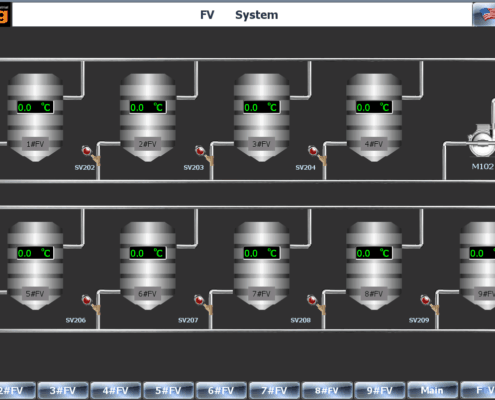

How to Automate a Microbrewery

As we all know, brewing is a very interesting thing, but it is…

History of Beer

Beer is something that has become a staple in many parts of the…