KEG WASHER

As every beer brewer knows, the Keg is a very important tool used during the storage and transport stages of beer production.

After a keg has been used, a thorough cleaning and sterilization needs to be done before a keg can be used for beer production again. An excellent keg washer makes the cleaning process easier and more efficient. Because of this, keg washers are considered to be a great labor saving and cost effective brewery tool.

Keg Machine

A YoLong keg machine is highly efficient, easy to operate, and versatile: microbrewery productivity is increased when a YoLong keg machine is installed. All you need to do for quick and easy installation is manually load the keg onto its dedicated work surface (such as the table seen above), and the rest of the operation is PLC controlled. You won’t need to read through a manual in order to understand how to connect your new keg washer: it comes with automatic connectors locking into the spears, an individual two-station operated cleaning system, and precisely engineered airtight interlocking parts. Every cleaning cycle contains high and low flow cleaning via a pulse valve, and this is what allows for an efficient operation that thoroughly cleans the keg stem.

Advantages

- The overall structure of a YoLong keg washer is classically compact which frees up the floor space of the brewery for other things. The modern slide design allows your keg machine more flexible mobility.

- It’s possible to request a custom-made style, size, and design. Every YoLong keg washer-and all of our brewery equipment-can have the voltage custom-adapted according to the voltage and electrical current supply and regulations in your country.

- Different types of spears can be matched. For example, A, S, G, and D spears can be custom-made and specially matched to your keg washer.

- Alternate heating methods can be included, based on the client’s specifications, such as, the choice between using steam or electricity for heating.

- The YoLong operation process is more intelligent and labor-saving, with automatic connectors that lock the keg spear in tightly, so that the rest of the process can be controlled by the PLC automatic program.

- Easy operation and integration HMI touch screen design. All you have to do is choose which cleaning process you want (plan A or plan B) on the touch screen, and the rest of the work is done for you by the YoLong keg washer. Different system parameters can be set on the screen, such as cleaning length of time or caustic cleaning agents temperature.

Installation

- Installation requirements: An electricity source, a water source, an air venting outlet source, CO2, and drainage facilities.

- Place your YoLong keg washer machine on its dedicated work station; adjust footing screws for correct balance.

- Connectors from left to right are as follows: hot water, sterile steam/clean water (Ro water), CO2, sterile air.

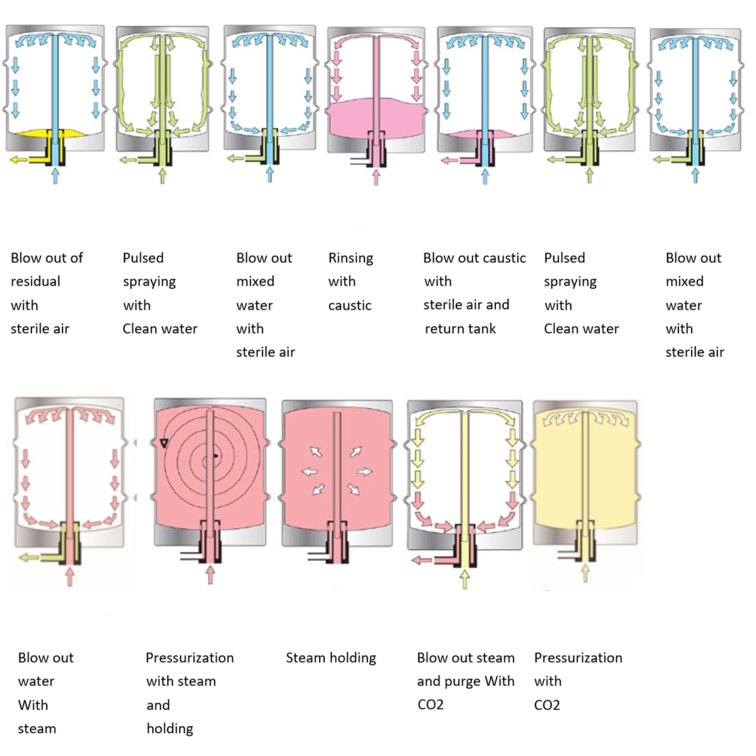

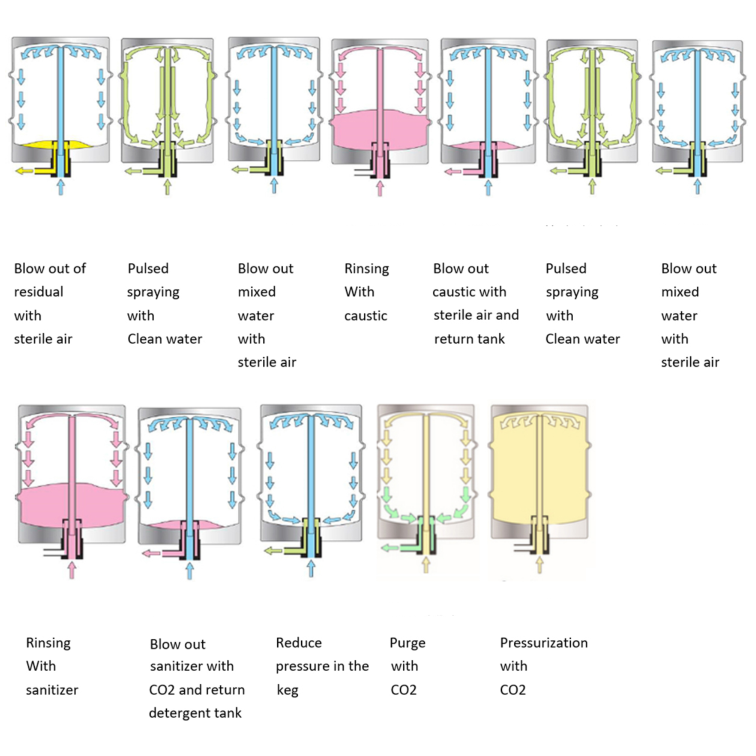

Keg washer cleaning process schematics

Plan A: Cleaning process with steam

Steam Heated Cleaning Process

Plan B: Cleaning process with electric

Electric Heated Cleaning Process

gallery

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!