Everything You Need to Know About Kettle Souring

What Is Kettle Souring?

What is kettle souring? It is a brewing technique which allows the brewer to sour unfermented wort very quickly, between 24 and 72 hours in most cases.

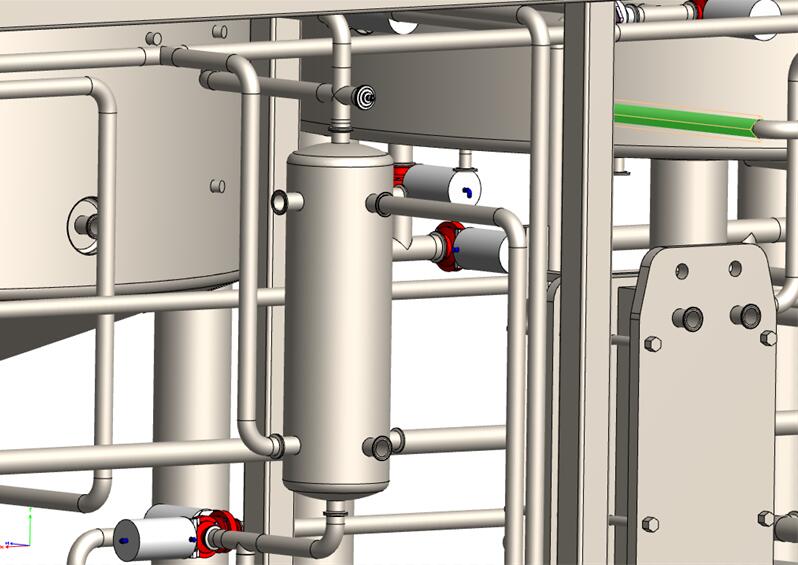

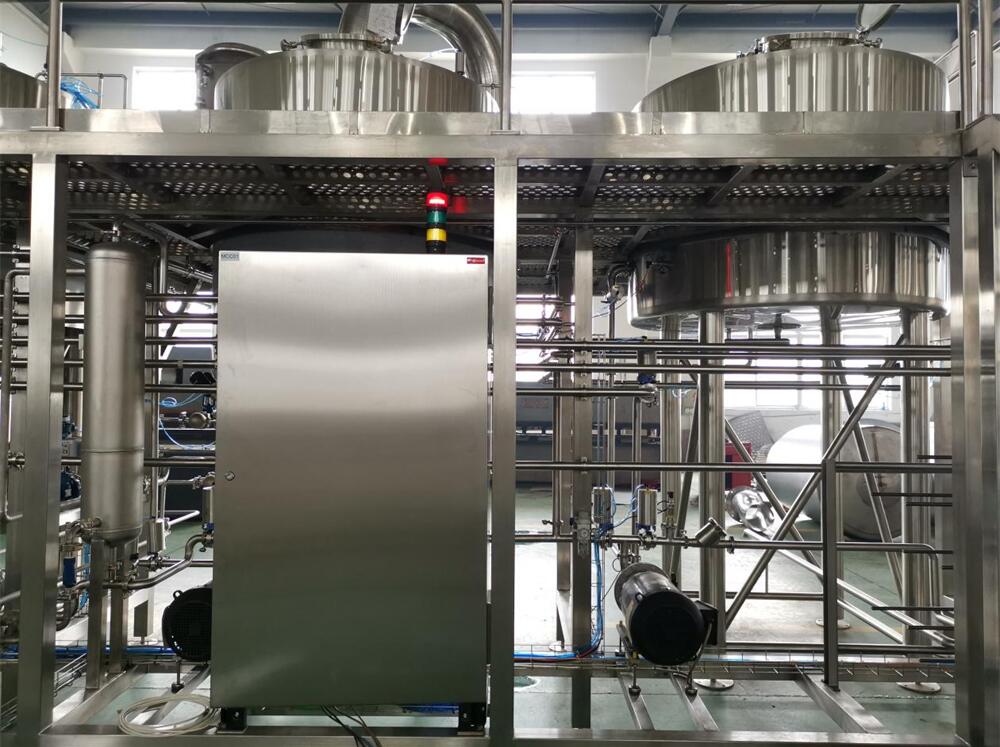

The “kettle” is a piece of brewery equipment called the brew kettle, the vessel in which the beer is soured. It is a stainless-steel mash tun where the souring process takes place, and then the beer is left to ferment in a tank. The key difference between kettle sours and traditional sours is that a steel vessel is used, as opposed to a barrel.

Why Use Kettle Souring?

Souring a beer using the kettle souring technique offers the brewer several benefits.

-

- Time frame: Being able to turn a beer sour quickly, while maintaining all the other important key taste notes, is an obvious benefit of kettle souring.

- No contamination: The wort is soured and then boiled to kill off the Lactobacillus Acidophilus, and there’s no worries about contaminating other batches or infecting any other equipment in your fermentation area.

- Flavor control: The Lactobacillus is extremely sensitive to isomerized alpha-acids (as little as 2 IBUs!); this souring method allows you to make a beer packed full of hoppy flavor, far more so than what is possible when using the traditional method.

How to Prepare Sanitary Wort?

Before pitching the Lactobacillus, the wort must be prepared.

The wort is flash-boiled for about 10 minutes to kill off any organisms that have survived up to this point. This process also drives off oxygen introduced into the mix, and this helps protect against unwanted bacteria blooms.

What Should the Wort Temperature Be for Kettle Souring?

115°F (46°C) is the standard temperature for kettle souring with Lactobacillus, but brewers each have their own magic temperature, anywhere between 95°F (35°C) to 115°F (46°C). These temperatures provide the best mix of flavor and speed for a quick sour beer.

If the brewer is using a lactic acid bacteria obtained from a commercial provider (as opposed to getting it from natural sources), it’s always best to follow the pitching rate and temperature recommended by the provider.

After boiling, the wort has to be cooled down to around 95 – 115ºF (35-46ºC) in order to incubate the lactobacillus, depending on the strain. This is easily done by running the wort through a tube heat exchanger. Not only does this cool the wort, but also provides sanitization (although hot wort also provides a certain degree of protection from unwanted bacteria blooms).

What should the Wort Ph be for Kettle Souring?

Pre-acidification of the wort to pH 4.0-4.5, accomplished by using a food grade standard acid (lactic or phosphoric), does wonders when it comes to inhibiting other bacterial strains that may be present in the wort (such as enteric bacteria). Lactobacillus does not produce protease that breaks down foam proteins below pH 5.0.

This acidification also hampers the enzyme action Lactobacillus utilizes when it comes to breaking down proteins. This means the resulting beer will showcase all the head retention and body that you would expect from a beer fermented using only Saccharomyces.

During this time, CO2 can be added on top of the wort (or bubbled through it) to create a ‘bed’. This prevents any further aerobic bacterial action. Alternatively, another jacketed vessel, such as a fermenter or a wort receiver, can be purged with CO2 and the wort transferred into this vessel to free up your kettle for more brewing.

Pitching Lactobacillus Guide

For fresh grain, roughly 2L (roughly 2.5 lbs or 1.15 kg) of grain per 10/bbl in a mesh bag held at 115ºF (46ºC) will drop pH from 5.2 to 3.2 in about 14 hours.

For other methods, between 100ºF-118ºF (38ºC-48ºC) may work. Begin with a starter batch if you are uncertain.

Again, if you are using lactic acid bacteria from a commercial provider, follow the pitching rate and temperature they recommend.

What should the Wort Ph be After Kettle Souring?

The target final pH should be between 3.0 and 3.5, depending on the desired sour taste of your recipe.

Kettle Souring Tips and Hints

- Don’t forget to boil wort again after kettle souring.

- Don’t use any hops until the final boil. Hops severely inhibit Lactobacillus.

- Pitch plenty of yeast when you’re ready for fermentation. The yeast cells will have to fight a bit against the acidity.

That’s all the recommendations we have to give on this very interesting (and delicious!) process. Please contact the YoLong team if you would like any more advice on equipment.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!