What Brewhouse System should I use?

In addition to obligatory sensors, such as sensors that are integrated into the system to monitor temperature and reduce errors during operation, brewing is made more convenient and controllable when other types of sensors are introduced into the equipment.

With this in mind, YoLong has begun production on two new and practical sensors: (1) flow switches and (2) pressure switches. Not only is this technology cutting edge innovation, but we produce the sensors to the very highest quality and make them available to you at the best price.

The YoLong pressure switch sensor:

There are many types of pressure switches. At present, integrated into our saccharification equipment, a pressure sensor switch is used to detect compressed air. The most commonly used sensor types are electronic and mechanical.

Pressure sensor switch below / Image copyright: YoLong Brewtech

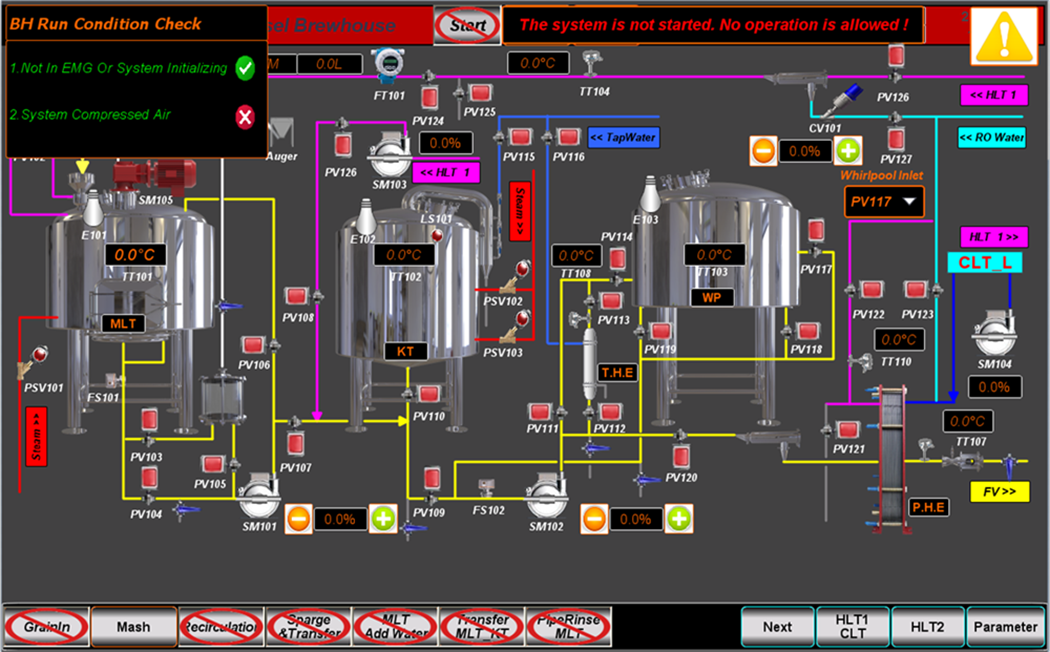

For any Brewhouse System with pneumatic valves, integrating a pressure switch can enhance equipment performance by continuously monitoring operating conditions.

Such a pneumatic system setup is ideal for winemakers. Why? Because it is often easy to forget to turn on the system’s compressed air before brewing. With the integration of a YoLong compressed air detection sensor into the system, the compressed air pressure value of the system will be lower than the set value. This means the Brewhouse System sensors are in place as both a fail-safe and a reminder.

Brewhouse system insufficient compressed air problems are so easily to avoid when you get a YoLong pressure switch sensor installed.

The YoLong Flow Switch Sensor:

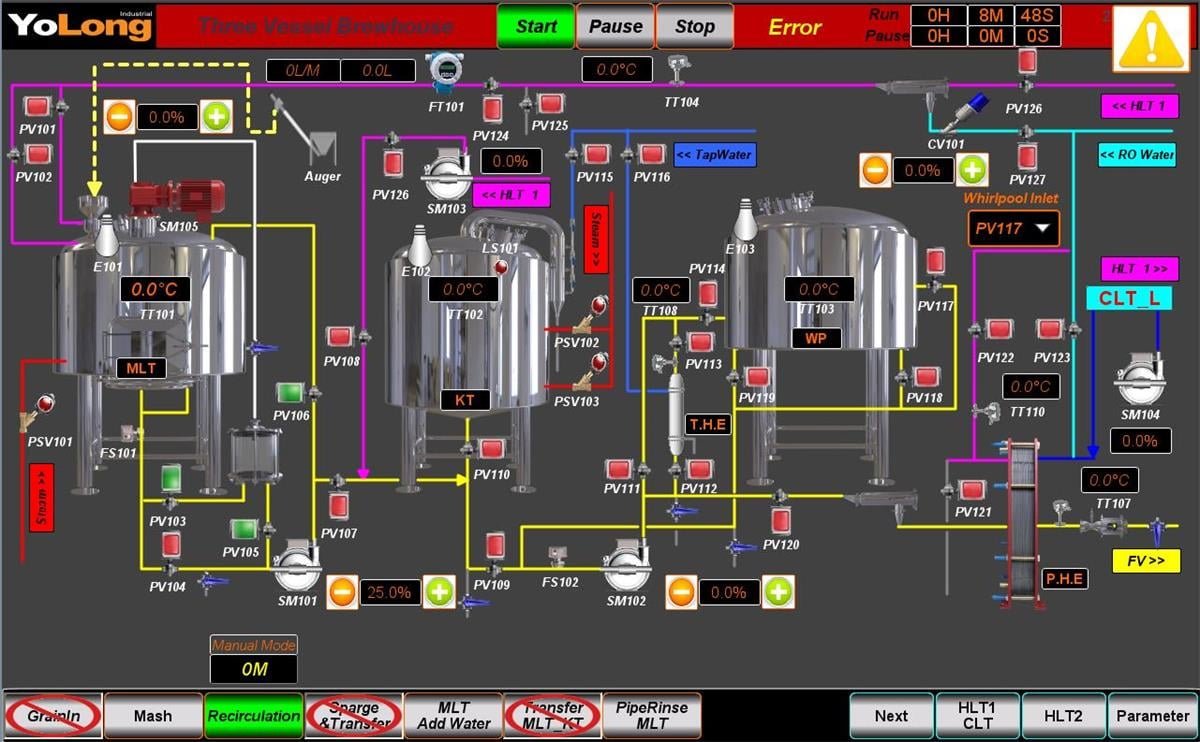

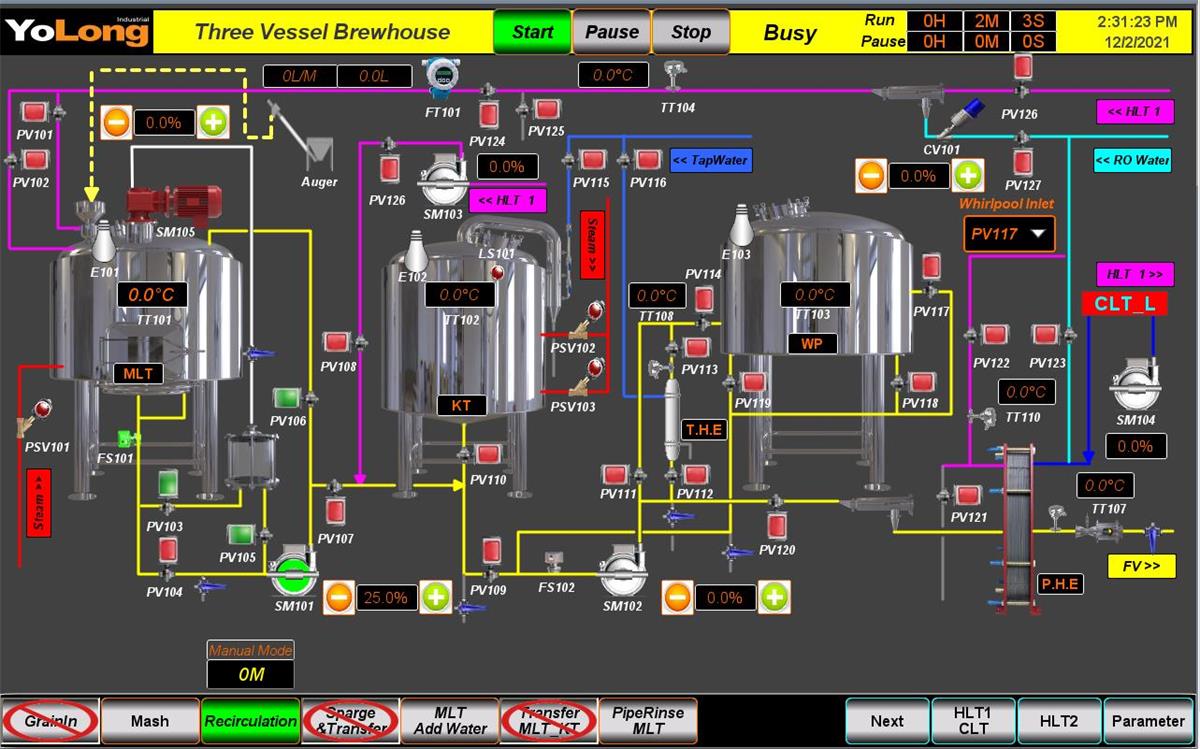

When the brewing system has a flow switch, it can helps to monitor the automatic processes of the system, and stop the process automatically once the material has been transferred.

A YoLong flow switch sensor also prevents the motor from stopping or starting if the valve is opened or closed incorrectly. This helps prevent long term damage to the motor seal caused by the dry rotation of the motor.

Image copyright: YoLong Brewtech

Image copyright: YoLong Brewtech

Additionally, with the HMI, the system error information automatically sends a text message, meaning the winemaker will be immediately alerted if an error has occurred. Instant troubleshooting and problem solving at your fingertips – and improved winemaking efficiency!

Brewing is made more fun when you have easy access to successful monitoring and automation!

With the development of brewing-related science and technology happening so quickly, you can bet that more Brewhouse System sensors will be invented; when they are, YoLong will proudly integrate more sensors and switches into our brewing systems.

YoLong customers can select which is the best sensor for immediate equipment enhancement and easier monitoring of the brewing process. Please contact us if you would like to discuss and plan according to your budget.

Remember: Sensors not only improve productivity and efficiency, but they also increase the equipment’s longevity and viability.

Both the pressure sensor and flow sensors are YoLong most popular equipment update installations: they have the greatest effect on productivity at the smallest price. Keep your ear on the ground for news about other YoLong sensors in the pipeline. We plan on making winemaking easier for you today and in the future.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!