YoLong Brewtech-Brewery Equipment

One-stop Brewing Equipment Manufacturer. Free Consulting & Design Service, Factory Price. Cost-effective, Avant-arde Design.

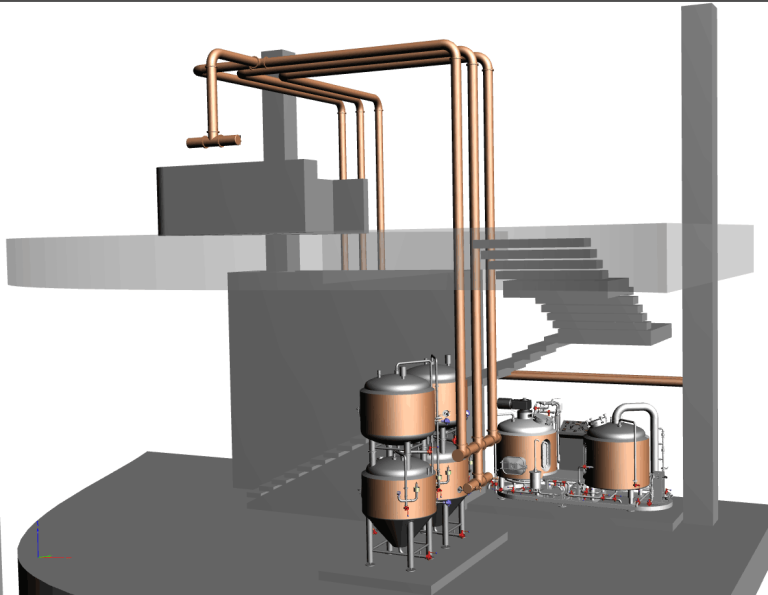

Microbrewery Equipment Brewing System for sale

Categories

- MALT TECHNOLOGY (1)

- BREWERY TANK (8)

- BREWING SYSTEM (6)

- HOP TECHNOLOGY (2)

- YEAST TECHNOLOGY (2)

- SS TANK (5)

- CONTROL SYSTEM (2)

- PROCESS SYSTEMS (1)

- PACKAGE MACHINE (1)

What equipment is needed to start a microbrewery?

To start a microbrewery, you will need various equipment and tools for the brewing process, as well as for packaging, storage, and serving. Here’s a list of essential equipment:

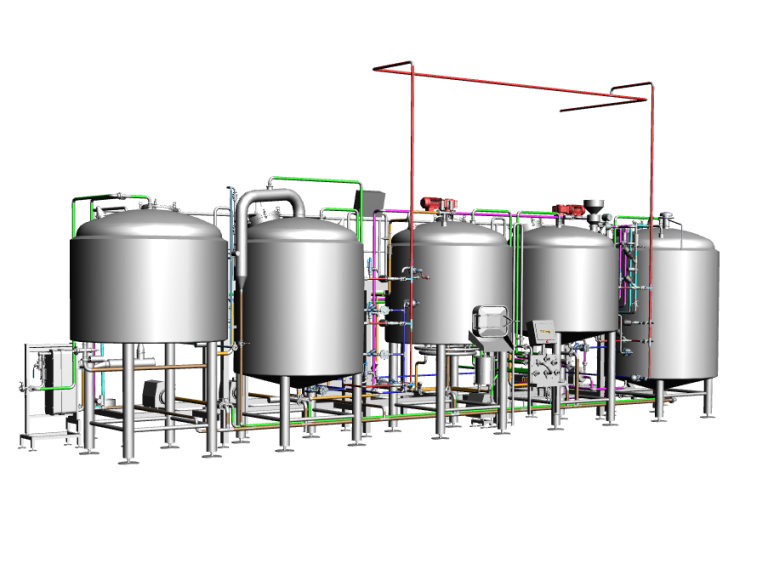

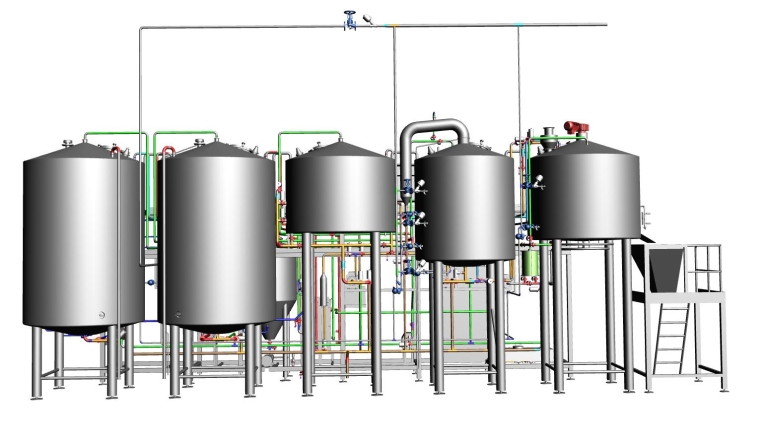

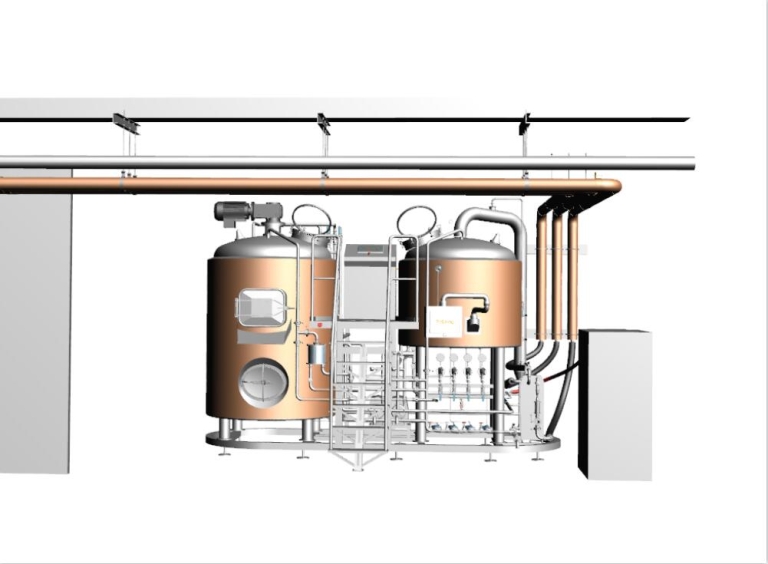

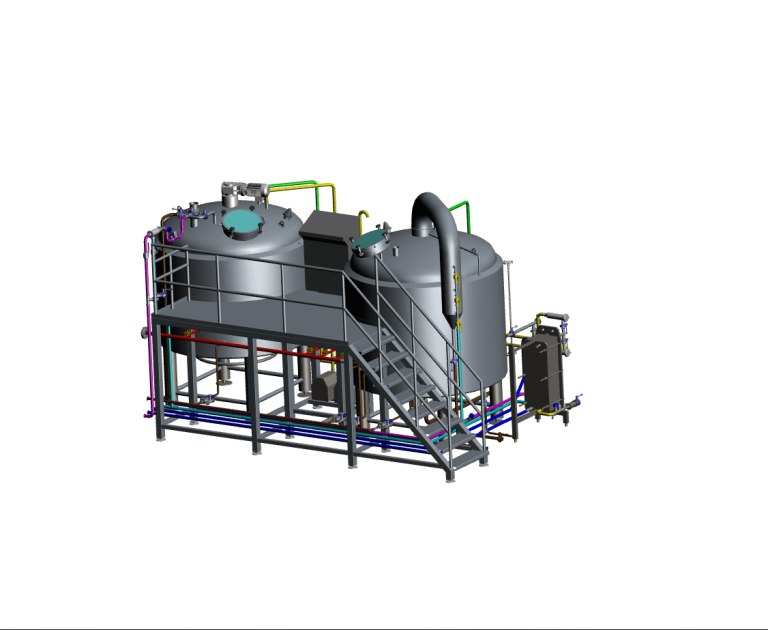

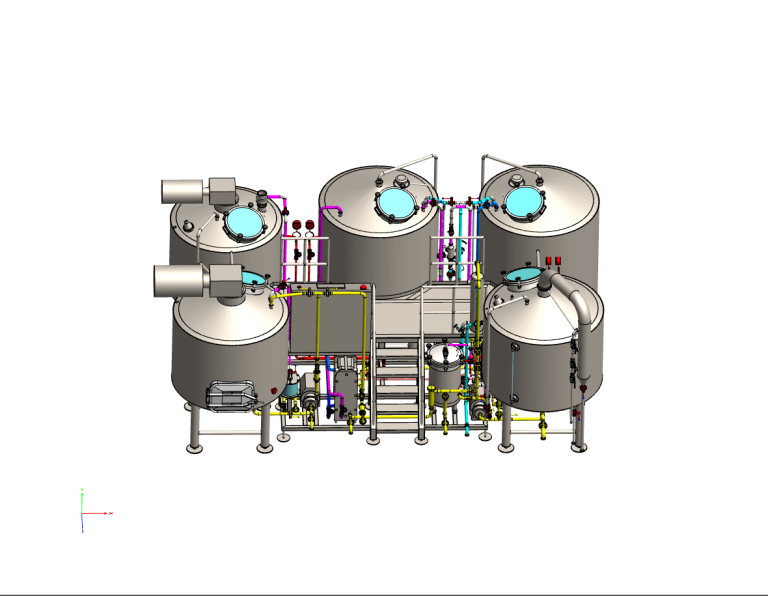

- Brewing system: A complete brewing system typically includes a mash tun (for mashing), a lauter tun (for lautering), a brew kettle (for boiling), and a whirlpool tank (for separating hops and trub from the wort).

- Fermentation tanks: These tanks are where the wort will ferment into beer, with the help of yeast. There are various types of fermentation tanks, such as conical fermenters and cylindrical fermenters.

- Brite tanks or serving tanks: After fermentation, the beer is transferred to these tanks for maturation, clarification, and carbonation before it is ready for packaging or serving.

- Cooling and temperature control systems: A glycol chiller system is used to maintain the proper fermentation temperature and regulate the temperature of the brite tanks.

- Hot liquor tank: This tank is used to store and heat water for mashing and sparging during the brewing process.

- Grain mill: A grain mill is used to crush malted grains before mashing.

- Heat exchanger: A heat exchanger, or wort chiller, is used to cool the wort quickly after boiling to prepare it for fermentation.

- Pumps and piping: Pumps and hoses are necessary for transferring liquids between various vessels throughout the brewing process.

- Kegs, bottles, or cans: Depending on your preferred packaging method, you will need kegs, bottles, or cans to store and distribute your finished beer.

- Kegging or bottling/canning equipment: This equipment is necessary for filling, sealing, and labeling your beer containers.

- Cleaning and sanitizing equipment: Proper cleaning and sanitation are crucial to maintain hygiene and prevent contamination. You will need equipment like brushes, chemical sanitizers, and a clean-in-place (CIP) system for larger tanks.

- Quality control and testing equipment: Various instruments, like hydrometers, thermometers, and pH meters, are essential for monitoring and maintaining the quality of your beer during the brewing process.

- Storage and handling equipment: This includes shelving, pallets, and forklifts for storing raw materials and finished products.

- Taproom equipment: If you plan to operate a taproom, you’ll need serving equipment like draft systems, glassware, and refrigeration units.

Remember that specific equipment requirements may vary depending on the scale of your microbrewery and the types of beers you plan to produce.

How do I choose the right size and capacity for my microbrewery equipment?

Choosing the right size and capacity for your microbrewery equipment depends on several factors, including your production goals, available space, budget, and growth plans. Here are some steps to help you make the right decision:

- Determine your production goals: Start by estimating the volume of beer you want to produce annually. This decision will be influenced by factors such as your target market size, distribution plans, and local demand. Your production volume will help determine the brewing system size and the number of fermentation and brite tanks you’ll need.

- Consider batch size and brewing frequency: Decide on the size of each batch and how often you plan to brew. Smaller batch sizes allow for more experimentation and variety in your beer offerings, while larger batches can provide cost efficiencies. Your desired batch size and brewing frequency will help determine the capacity of your brewing system and fermentation tanks.

- Assess available space: Measure the space available in your brewery location, taking into account the ceiling height, floor space, and any restrictions for installing and operating the equipment. Make sure there’s enough space for brewing, fermentation, storage, packaging, and any other operations, as well as room for future expansion if needed.

- Factor in future growth: When selecting equipment, consider your plans for scaling up your production in the future. Investing in slightly larger equipment from the start can save you money in the long run if you plan to expand your operations. However, be cautious not to oversize your equipment too much, as this can lead to inefficiencies and higher energy costs.

- Evaluate budget constraints: Your budget will play a significant role in determining the size and capacity of your microbrewery equipment. Balance the need for quality equipment with affordability, and consider options such as used equipment, leasing, or financing to help manage your budget.

- Research equipment suppliers: Compare different equipment suppliers, taking into account factors like product quality, customization options, after-sales support, and shipping costs. Read reviews, ask for recommendations from fellow brewers, and attend industry events to gather information about different suppliers.

- Consult with experts: Reach out to experienced brewers, consultants, or industry professionals for advice on choosing the right equipment size and capacity for your microbrewery. They can provide valuable insights based on their experience and knowledge of the industry.

Once you’ve considered all these factors, you’ll be better equipped to select the right size and capacity for your microbrewery equipment, ensuring a balance between your production goals, space, budget, and growth plans.

What is the difference between commercial brewery equipment and microbrewery equipment?

Commercial brewery equipment and microbrewery equipment both serve the same purpose of producing beer. The main differences between the two lie in their scale, capacity, complexity, and cost. Here are some key distinctions:

- Scale and capacity: Commercial brewery equipment is designed for larger-scale beer production, typically found in regional or national breweries. These breweries produce higher volumes of beer compared to microbreweries, which are smaller-scale operations, often focused on craft beers and serving local markets. Consequently, commercial brewery equipment has a higher brewing capacity than microbrewery equipment.

- Complexity: Commercial breweries often utilize more complex and automated systems for various stages of the brewing process. These advanced systems can provide better control and consistency in beer production but come at a higher cost. In contrast, microbreweries often use simpler, more manual systems that allow for more hands-on control and flexibility in brewing, which can be beneficial for experimenting with unique beer recipes and styles.

- Cost: Due to the larger scale and higher complexity, commercial brewery equipment is typically more expensive than microbrewery equipment. Microbrewery equipment is designed to cater to smaller budgets and operations, making it more accessible for those looking to start a craft brewery or brewpub.

- Customization and flexibility: Microbrewery equipment is often more customizable and flexible, as it caters to the diverse needs of small-scale brewers who may want to experiment with different beer styles and recipes. Commercial brewery equipment, on the other hand, is generally designed for more standardized, high-volume beer production.

- Space requirements: Commercial brewery equipment requires more space for installation and operation due to its larger size and capacity. Microbrewery equipment is designed to fit into smaller spaces, making it suitable for urban settings or locations with limited square footage.

In summary, the main differences between commercial brewery equipment and microbrewery equipment are their scale, capacity, complexity, cost, and space requirements. The commercial brewery equipment is designed for large-scale beer production with more automation and higher costs, while microbrewery equipment is tailored for smaller-scale operations with simpler systems, lower costs, and greater flexibility for experimentation.

How much does microbrewery equipment cost?

The cost of microbrewery equipment can vary significantly depending on factors such as the size and capacity of the equipment, the quality and brand of the equipment, the level of automation, and whether you are purchasing new or used equipment. Here’s a rough cost estimate for some key microbrewery equipment:

- Brewing system: A small-scale brewing system (1-10 barrels) can range from $10,000 to $150,000 or more, depending on the size, material, level of automation, and brand. Larger systems (10-30 barrels) can cost from $100,000 to $500,000 or more.

- Fermentation tanks: The cost of fermentation tanks depends on their size and material. For example, a 1-10 barrel stainless steel fermentation tank can range from $2,000 to $10,000 or more, while larger tanks (10-30 barrels) can cost from $6,000 to $20,000 or more.

- Brite tanks: Similar to fermentation tanks, the cost of brite tanks depends on their size and material. A 1-10 barrel stainless steel brite tank can range from $2,000 to $8,000 or more, while larger tanks (10-30 barrels) can cost from $5,000 to $18,000 or more.

- Cooling and temperature control systems: A glycol chiller system for a small microbrewery can cost between $5,000 and $15,000, depending on the size and capacity of the system.

- Grain mill: A grain mill for a small microbrewery can range from $500 to $3,000 or more, depending on the quality and brand.

- Kegging or bottling/canning equipment: Manual kegging or bottling equipment can cost from $1,000 to $10,000, while more automated systems can range from $10,000 to $100,000 or more, depending on the level of automation and throughput.

- Other equipment: Additional costs for items like heat exchangers, pumps, hoses, cleaning and sanitizing equipment, and quality control equipment can add several thousand dollars to your total investment.

These are rough estimates, and the actual cost of microbrewery equipment can vary widely based on your specific needs, equipment choices, and supplier options. It’s essential to research various equipment suppliers, compare prices, and consider factors like warranty, after-sales support, and shipping costs before making a decision.

Additionally, keep in mind that there will be other costs associated with starting a microbrewery, such as building and infrastructure, permits and licensing, raw materials, labor, marketing, and distribution. Considering used equipment, leasing, or financing options can help manage the initial costs of setting up your microbrewery.