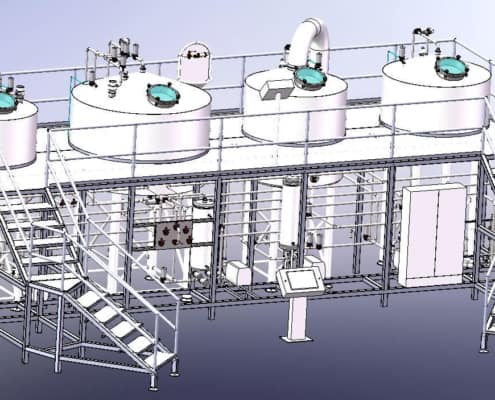

What Is the Best Source to Buy Commercial Equipment to Create A Micro-Brewery?

If you are allegedly into brewing beers, likely for yourself,…

Nano-Scale Brewing: Revolutionizing Craft Beer on a Micro Level

Nano-scale brewing is transforming the craft beer industry,…

Is It Cost Efficient to Have A Microbrewery at Home?

Even though the expression "microbrewery" was initially utilized…

Do Micro and Nano Breweries Generally Filter their Beer Before Kegging?

Microbrewery, also known as a craft brewery, is a small-scale…

How to brew commercial beer

Infusing Beer Commercially

In as much a significant number of…