The Basic Brewing Steps, Principles and Equipment Selection of Home Brewed Beer

Alcohol has in general, been an integral part of society for…

Top Beer Brewing Equipment for Beginners

Brewing beer is more than just a hobby—it's an art, a science,…

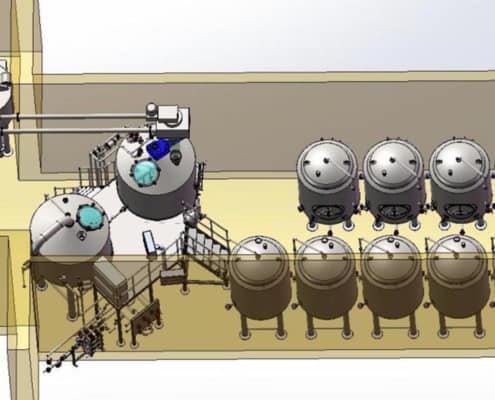

Micro-Brewing Equipment

Overview: What is Micro-Brewing Equipment?

Micro-brewing…

Home Brewing Equipment

Overview: What is Home Brewing Equipment?

Home brewing equipment…

Advice on home brewery equipment for making light beer

People who used to make light beer at home must have had some…

How to start a beer brewing business?

Beer brewing is more like an art. It is an art that has a tweak…