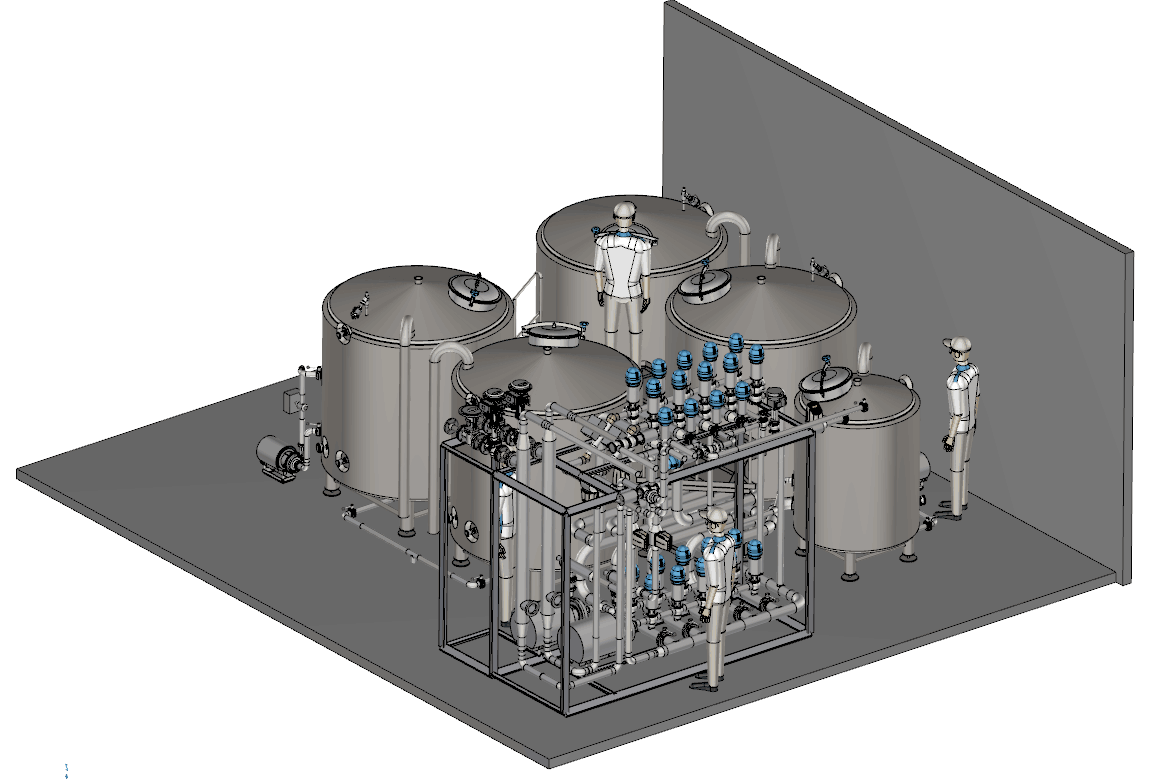

CIP STATION

CIP System

YoLong supplied kinds of food processing equipment and beverage processing equipment, mainly including processing tanks, CIP system, dairy processing equipment and milk processing equipment.

CIP(clean in place) station is a important part in the brewing system, which is mainly used to clean wort and other trubs in the brewing tanks. YoLong will design and custom the CIP system.

The CID system including different vessels to use chemical clean brewery tanks, including acid tank, caustic tank, hot water tank, recovery tanks, ect, which can be combined single vessel to four vessel CIP station.

CIP System

Specifications

- Top conical head with manway

- Capacity from 2bbl to 50bbl

- CIP capable

- Overflow tube

- Temperature sensor in thermowell

- Optional liquid level sensor

- Cone bottom with discharge

- Mineral wool insulation

- Mounted on three cylindrical legs with adjustable feet

- Design pressure, atmospheric

- Material, 304 stainless steel

- Inside finish, #2B, Ra<32

- External finish, #4

- Insides welds, removed and polished to #4

- Outside welds, clean with heat stain removed

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!