Wort Aeration & Oxygenation-Brew Your Best Craft Beer

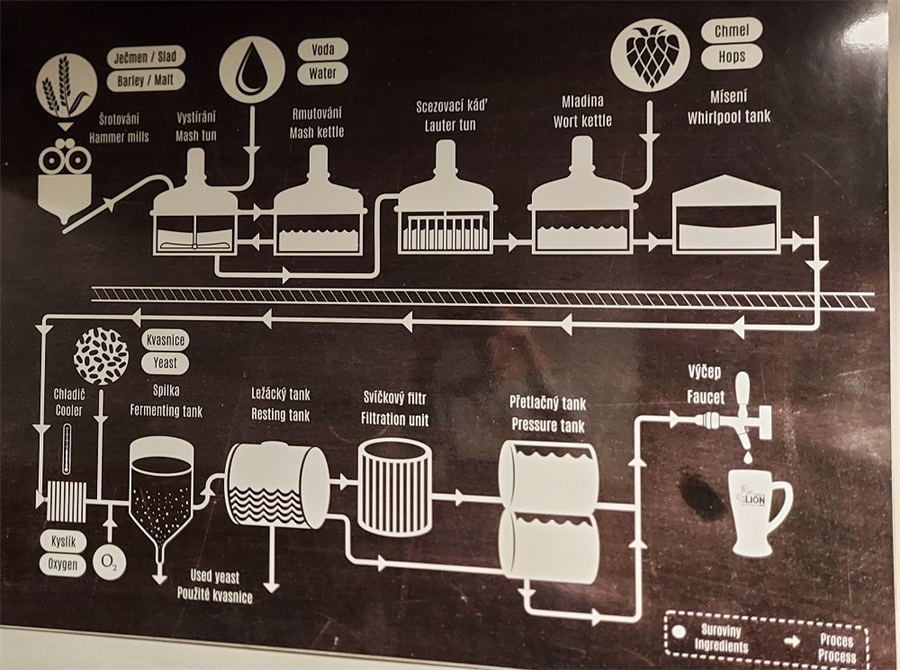

Whether you use small brewing equipment, or medium-sized 10BBL-20BBL brewing equipment, or commercial brewing equipment above 30BBL. In the beer production process, the brewing masters are trying their best to prevent beer or fermentation broth from contacting air. The main reasons are:

- Worry about the oxygen in the air oxidizing the beer, causing the beer to become turbid, darker in color, and produce unpleasant smells and tastes.

- Worry about the uncontrollable transformation of various microorganisms in the air to beer fermentation in the fermenter.

- Worry about that leads to an increase in beer spewing and bottle bursts.

However, neither the expanded cultured yeast nor the recovered yeast after fermentation is sufficient to form the amount of yeast required for beer fermentation. Therefore, after the yeast is added, in order to propagate the yeast, the yeast must be activated, so it is necessary to provide enough for the yeast. In order to avoid the oxidation of wort caused by oxygenation, oxygenation is performed after the wort is cooled to a certain temperature and the oxygen content of the wort is appropriately controlled.

After the wort is boiled, there is basically no pollution. All related containers and pipes have also been CIP cleaned. Therefore, the first consideration for wort is that the added air is sterile, so it will pollute the fermentation during the oxygenation process. The main consideration is: the aseptic filter of the air itself from the outlet of the sterile filter to the sterility of the air adding wort pipeline (here in addition to the design of the pipeline system that needs to consider CIP, in-situ steam sterilization is also required .)

According to the brewing process and brewing experience, the oxygenation of wort is generally in the range of 6-10mg/L wort, less than 6mg/L. It is generally believed that insufficient oxygenation will cause poor yeast reproduction and affect sugar reduction and fermentation. Not vigorous, prolong the fermentation time, etc…

Above 10mg/L, it is generally considered that over-oxygenation will easily increase fatty acids and sterols.

The plan of wort oxygenation:

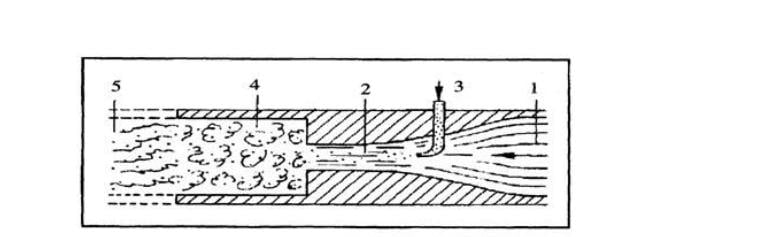

- Device using venturi method

The venturi tube is a section of tube with different cross-sections, narrowing from both ends to the middle, and its smallest part is called the throat. When the wort flows through, the flow rate increases and the pressure decreases due to the reduced cross-section of the tube. The flow rate at the neck of the throat is the largest and the pressure is the smallest. Here the branch pipes with sterile air are introduced, and the high-speed wort can inhale and disperse the sterile air into small bubbles, which is the close contact between gas and liquid, so as to achieve the purpose of dissolving oxygen in the wort.

- Device using sintered material method with surface micropores

The air passes through the titanium rod or other sintered materials with micro-pores on the surface, so that the air escapes from the surface in the form of tiny bubbles, and then it is in contact with the wort and merged into the wort. Due to the micro-holes, it is relatively difficult to clean in CIP. After a period of use, it may cause the need to increase the pressure of the supply air, or need to be disassembled and soaked for thorough cleaning.

For any other enquiry you may have please search and read our FAQ section. If you still haven’t found what you are looking for our support team is always ready with an answer at [email protected] , now also available on WhatsApp.

Frequently Asked Questions (FAQ)

1) How much dissolved oxygen (DO) should I target in wort for Craft Beer?

- Ale wort: 8–10 mg/L DO. Lager wort: 10–12 mg/L DO. High-gravity (>18°P): up to 12–14 mg/L via staged oxygenation. Avoid >14 mg/L to limit lipid/sterol overproduction.

2) When should I oxygenate the wort?

- After knockout and chilling to fermentation temperature (typically 10–20°C), during transfer into the fermenter. Do not oxygenate hot wort (oxidation risk) or after yeast growth phase begins.

3) Air vs. pure O2—what’s better?

- Sterile air can reach ~8 ppm at 20°C; pure O2 can achieve 10–12+ ppm quickly. Air is economical; O2 offers precise control for strong ales/lager pitching rates. Always use sterile filtration regardless.

4) Which oxygenation device is best: venturi, sintered stone, or inline mixer?

- Venturi: low-cost, simple, moderate mass transfer. Sintered stone (titanium/SS): high transfer, requires rigorous CIP/SIP. Static inline mixer: excellent dispersion with lower gas use; higher upfront cost.

5) How do I verify I’m hitting my DO setpoint?

- Use a calibrated DO meter inline or at the fermenter inlet; log temperature, flow, and gas rate. Validate with step tests (vary gas flow) and correlate with fermentation kinetics (lag time, VDK).

2025 Industry Trends: Wort Aeration & Oxygenation for Craft Beer

- Precision oxygen dosing: mass-flow controllers linked to Plato and flow sensors set DO automatically per recipe.

- Inline analytics: dissolved oxygen probes and optical Brix sensors at knockout standardize yeast growth and reduce batch-to-batch variance.

- Sterility assurance: SIP-able gas trains with 0.2 μm sterile filters and integrity testing before each brew.

- Energy and gas efficiency: static mixers and pulsed O2 reduce gas consumption 15–30% vs. continuous sparge.

- Yeast health programs: oxygenation tailored to pitch rate, glycogen/trehalose status, and repitch generation count.

2025 Benchmarks and Settings

| Parameter | Ales | Lagers | High-Gravity Ales (≥18°P) | Notes/Sources |

|---|---|---|---|---|

| Target DO at knockout | 8–10 mg/L | 10–12 mg/L | 12–14 mg/L (staged) | ASBC/MBAA guidance |

| Gas type | Sterile air or O2 | O2 preferred | O2 required | Air caps near 8 ppm at 20°C |

| Stone pore size | 0.5–2 μm | 0.5–1 μm | 0.5 μm | Smaller pores = finer bubbles |

| Typical gas flow (per hL) | 0.5–1.5 L/min | 0.8–2.0 L/min | 1.5–3.0 L/min | Adjust by wort temp/flow |

| Verification | Inline DO + grab sample | Inline DO + grab sample | Inline DO + staged re-dose at 2–4 h | Document in brewsheets |

References:

- American Society of Brewing Chemists (ASBC): https://www.asbcnet.org

- Master Brewers Association of the Americas (MBAA): https://www.mbaa.com

- Brewers Association (BA): https://www.brewersassociation.org

Latest Research Cases

Case Study 1: Mass-Flow Controlled Oxygenation Improves Consistency (2025)

Background: A 15 bbl Craft Beer brewery saw variable lag times and VDK in lagers.

Solution: Added inline DO probe, static mixer, and mass-flow O2 tied to Plato and wort flow; sterile gas filtration with integrity checks.

Results: Lag time variance reduced 48%; average packaged DO down from 80 to 52 ppb (via cleaner fermentation and closed transfers); 0.9-day reduction to terminal gravity.

Case Study 2: Staged Oxygenation for High-Gravity Stouts (2024)

Background: High-gravity (22°P) stout stalled at 66% ADF with single-dose O2.

Solution: Implemented two-step oxygenation: 12 mg/L at knockout, 6 mg/L at 6 hours post-pitch; increased pitch rate by 15%.

Results: Apparent attenuation improved to 78%; ester profile within spec; no increase in diacetyl incidents.

Expert Opinions

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

Key viewpoint: “Right-size oxygen to wort gravity and yeast physiology. Over-oxygenation wastes gas and can alter lipid metabolism; under-oxygenation prolongs fermentations.” - Ashton Lewis, Brewing Scientist and MBAA contributor

Key viewpoint: “Inline measurement at knockout is the single best upgrade. If you don’t measure DO, you’re guessing—and guesses add days and defects.” - John Mallett, Brewing Operations Leader, author of Malt

Key viewpoint: “Tie oxygenation to repeatable procedures—calibrated meters, verified sterile filters, and documented gas flows—so results scale from 10 bbl to 100 bbl.”

Practical Tools/Resources

- ASBC Methods for Dissolved Oxygen and Wort Analysis

https://www.asbcnet.org - MBAA Technical Quarterly: oxygenation best practices, device comparisons

https://www.mbaa.com - Brewers Association safety and cellar guides (SIP, sterile filtration)

https://www.brewersassociation.org - DO instrumentation and gas control vendors

Anton Paar, Hamilton, Pentair Haffmans, Mettler Toledo, Zahm & Nagel - Yeast health and pitching calculators

https://www.whitelabs.com | https://www.lallemandbrewing.com

SEO note: Internally link to “Craft Beer wort oxygenation,” “inline DO measurement,” “static mixer oxygenation,” “sterile air filtration,” and “high-gravity fermentation.”

Last updated: 2025-08-28

Changelog: Added 5 FAQs; 2025 trends with benchmark table and references; two recent case studies; expert viewpoints; and practical resources focused on wort aeration/oxygenation for Craft Beer

Next review date & triggers: 2026-02-01 or earlier if ASBC/MBAA publish new DO targets, major equipment innovations emerge, or yeast-management guidance changes

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?