the difference between APA and IPA(APA vs IPA)2025

*Last update: 22 February 2022 BY YoLng Brewtech

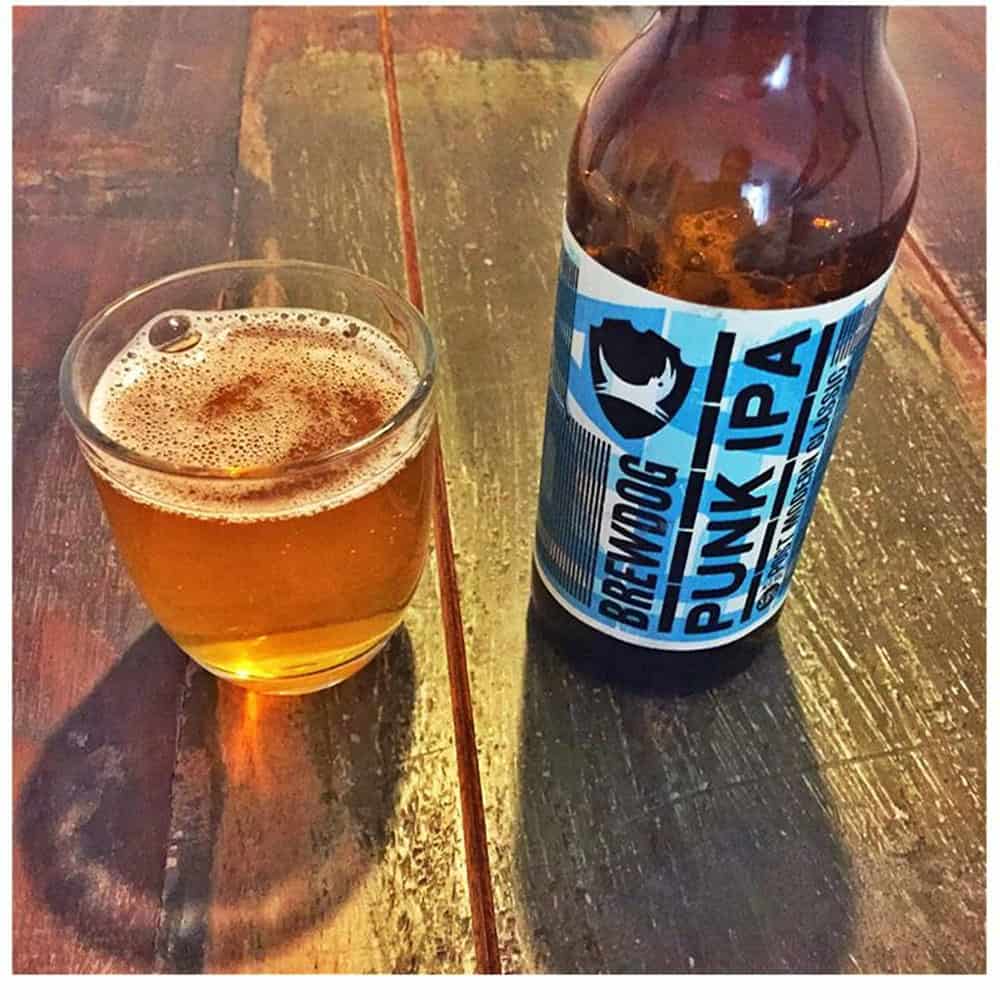

If you love the bitterness of beer, the aroma of your beer, and the freshness it brings to you, the Pale Ale family must be your best bet. Have you ever seriously thought about what “pale” means in “pale al” ? Or is it different from India Pale Ale?

You might wonder if you could simply use the color of beer to distinguish between Pale Ale or India Pale Ale, because Pale Ale is indeed mostly “Pale”, and most of the double Indian Pale Ale, with its strong bouquet, is actually darker. But the color of beer can only serve as a reference, and even the same beer can have different colors.

Pale Ale

As for why Pale Ale is called, it’s actually because it USES a lighter roast malt. In a typical pale ale, malt and hops are well balanced. Simply put, the sweetness of malt and the bitterness of hops are well combined. And pale ale’s hops, though clearly expressed, can be very mild.

English India Pale Ale (IPA)

The IPA was originally made with a large number of hops, designed to ensure that beer does not rot quickly on long voyages from England to India, because the hops are so preservative that they keep the beer fresh. IPA used to be, and still is, British hops (not necessarily now), and tends to reflect the aroma of soil, wood and spices.

American India Pale Ale (American IPA)

Today in the UK, winemakers are still brewing the traditional IPA, while American winemakers have incorporated their own unique ideas into the IPA, and the American IPA has changed. The American IPA tends to reflect a more intense and exciting bouquet. In the balance between malt and hops, American winemakers are more willing to highlight the bouquet. The typical American IPA is characterized by the aroma of resin, tropical fruit and grapefruit.

American Double IPA

The American double IPA, also known as the American Imperial IPA, is a unique American style that seeks to add more wine and flowers. Double IPA is produced in twice or even three times the amount of IPA, and more malt is added to balance the bitterness. The result is a stronger bouquet of hops and a higher alcohol content due to increased malt use.

English Pale Ale

English Pale Ale can be traced back to the town of burton on the river trent, which is rich in hard water. Hard water can make the body clear and make the hops more bitter. British pastel colours can range from gold to brownish red and are usually quite blistering. Usually you can taste the aroma and taste of fruit, hops, soil, butter and malt when you taste the British pale ale. Most of the materials used to make a typical British pale al come from the UK.

American Pale Ale (APA)

Originating from English Pale Ale, APA is now popular with beer lovers around the world, brewed with native American or imported materials. The product features a strong regional character. In general, APA tries to balance malt and hops. The fatty and creamy flavors of fruit and diacetyl in APA can range from zero to medium, and hops can range from light floral aromas to intense spicy aromas.

For information about the best beer brewing equipment and tanks contact us now!

When you taste your favorite beer, know that brewers are always testing new hop varieties and brewing methods.

Next year’s Indian Pale Ales and American Pale Ales may not be comparable to this year’s, as brewers continue to explore and experiment with new hop varieties and interesting ingredients.

Brewing Equipment for Producing Light Ale Beer

Brewing your own light ale beer can be one of the most satisfying ventures. Whether you’re a hobbyist or running a microbrewery, selecting the right brewing equipment is critical to achieving the perfect batch. This guide provides a detailed roadmap, covering everything from equipment selection to installation, operation, and maintenance, ensuring you can produce high-quality light ale beer consistently.

Overview of Brewing Equipment for Light Ale Beer

Brewing light ale beer involves a delicate balance of ingredients, timing, and equipment. Unlike heavier ales or lagers, light ales demand precise temperature control, proper aeration, and attention to detail in the mashing, fermentation, and packaging phases. The equipment plays a starring role in achieving the right flavor profile, clarity, and consistency.

Whether you’re upgrading your setup or starting fresh, the right tools will not only improve your brew but also streamline your brewing process, saving time and effort.

Essential Brewing Equipment Guide

Brewing equipment varies based on batch size, complexity, and customization needs. Below is a comprehensive guide to essential equipment for brewing light ale beer.

Mashing Equipment

The mashing process involves steeping crushed grains in hot water to convert starches into sugars. A mash tun is the primary tool here.

- Mash Tun: An insulated vessel designed to hold mash temperatures consistently.

- Mash Paddle: Used to stir the mash, ensuring even temperature and enzyme activation.

Boiling Equipment

The wort must be boiled to sterilize and extract flavors from hops.

- Kettle: A stainless-steel pot with a volume tailored to your batch size. Features like built-in thermometers and spigots improve efficiency.

- Burner or Heating Element: Provides a consistent heat source.

Fermentation Equipment

Fermentation transforms sugars into alcohol, and the right equipment ensures the beer develops its intended characteristics.

- Fermenters: Food-grade plastic, glass, or stainless-steel vessels equipped with airlocks.

- Temperature Control System: Ensures fermentation occurs at optimal temperatures.

Filtration and Clarification

For the crisp, clear appearance light ales are known for, filtration and clarification are crucial.

- Filters: Plate or inline filters remove sediment.

- Finings: Additives like Irish moss help in sedimentation.

Packaging

Once fermentation is complete, beer needs to be packaged for storage and distribution.

- Kegs or Bottles: Options depend on scale and preference.

- Carbonation System: Adds the right amount of fizz, crucial for the light ale experience.

Table of Equipment Types with Key Details

| Equipment Type | Function | Material | Special Features | Approximate Cost |

|---|---|---|---|---|

| Mash Tun | Converts starch to sugars | Stainless steel/plastic | Insulation, built-in thermometer | $200 – $2,000 |

| Kettle | Boils wort | Stainless steel | Volume indicators, spigot | $100 – $5,000 |

| Fermenter | Alcohol fermentation vessel | Glass/plastic/steel | Airlocks, temperature control options | $50 – $3,000 |

| Filtration System | Removes sediment and impurities | Stainless steel/plastic | Plate or inline filters | $150 – $1,500 |

| Packaging Equipment | Bottling or kegging beer | Stainless steel/glass | Automated or manual options | $300 – $5,000 |

Brewing Process for Light Ale Beer

The brewing process consists of five main stages: mashing, boiling, fermenting, conditioning, and packaging.

1. Mashing

Malt grains are steeped in a mash tun with hot water, usually at 65–70°C, to extract fermentable sugars. The duration typically spans 60 minutes. Consistency in temperature and proper stirring are essential for even sugar extraction.

2. Boiling

The sweet wort is transferred to the kettle and boiled for 60–90 minutes. Hops are added at specific intervals to develop bitterness, aroma, and flavor. A robust burner ensures a vigorous boil without scorching.

3. Fermentation

The boiled wort is rapidly cooled and transferred to the fermenter. Yeast is pitched, and the mixture ferments for 1–2 weeks at controlled temperatures. This stage is critical for achieving the signature taste of light ale.

4. Conditioning

Post-primary fermentation, the beer is conditioned to refine flavors and reduce off-notes. Secondary fermentation may occur in a separate vessel or during the packaging stage.

5. Packaging

The beer is carbonated and transferred to kegs or bottles. For light ales, achieving the right carbonation level is critical for enhancing its refreshing profile.

Customization and Space Considerations

| Feature | Details |

|---|---|

| Capacity | Batch sizes range from 1 gallon (homebrew) to 30+ barrels (commercial). |

| Space | Compact setups are available for small spaces, while large systems require dedicated rooms. |

| Design | Modular designs allow for upgrades and expansions. |

| Customization | Custom tanks, heating elements, and filtration systems are widely available. |

Suppliers and Price Ranges

| Supplier Name | Product Range | Price Range | Customer Support |

|---|---|---|---|

| Blichmann Engineering | Homebrewing to commercial equipment | $200 – $15,000 | Excellent post-purchase service |

| SS Brewtech | Premium stainless steel products | $300 – $20,000 | Known for durability |

| Grainfather | All-in-one systems | $800 – $5,000 | Intuitive designs for beginners |

| Spike Brewing | Customizable systems | $500 – $25,000 | Highly customizable solutions |

Installation, Operation, and Maintenance

| Aspect | Details |

|---|---|

| Installation | Follow manufacturer guidelines; some setups require professional assistance. |

| Operation | Automated systems simplify processes; manual setups demand close monitoring. |

| Maintenance | Regular cleaning prevents contamination; periodic inspections ensure longevity. |

How to Choose the Right Supplier

Choosing the right supplier is critical for a successful brewing operation. Factors to consider include reliability, customization options, and customer support.

| Parameter | Considerations |

|---|---|

| Reputation | Look for positive reviews and industry certifications. |

| Range of Products | Ensure the supplier offers compatible components. |

| Pricing and Warranty | Balance cost with warranty terms and after-sales service. |

| Customization | Check for tailored solutions for your specific needs. |

Comparing Pros and Cons of Brewing Equipment

| Aspect | Advantages | Limitations |

|---|---|---|

| Stainless Steel Equipment | Durable, easy to clean, professional appearance | Higher upfront cost |

| Plastic Equipment | Affordable, lightweight | Limited lifespan, potential for staining |

| Glass Fermenters | Non-reactive, visually appealing | Fragile, requires careful handling |

FAQ

| Question | Answer |

|---|---|

| What is the best material for brewing equipment? | Stainless steel is preferred for its durability and non-reactive properties. |

| How much space do I need for a homebrew setup? | A compact setup can fit in a small corner, requiring roughly 5–10 square feet. |

| Is automation necessary for brewing light ale? | Not essential, but it simplifies temperature control and consistency. |

| How often should equipment be cleaned? | Clean immediately after use to prevent contamination and residue buildup. |

Estimating the cost of brewery equipment

From equipment costs to brewery size, construction costs and licensing, brewery operating costs can vary widely depending on your specific operation.

When estimating the price of your investment, YoLong build each brewhouse on a case by case basis. The size and capacity of the brewhouse depends on what scale beer production is planned by the client. The brewhouse has different level of automatic control levels. We have Multiple types of equipment are available as well as brewery equipment financing options to help you get up and running.