The Art of Brewery with Copper Vessels

/Update October 22, 2022 / By YoLong Brewtech

Start Today

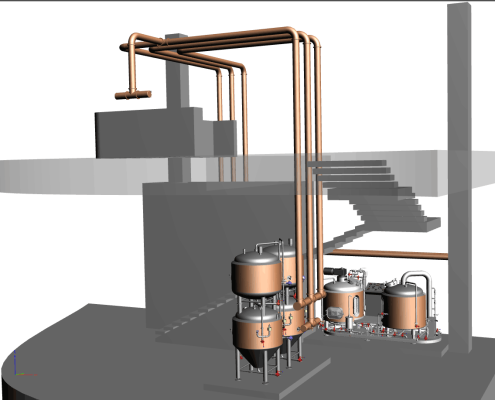

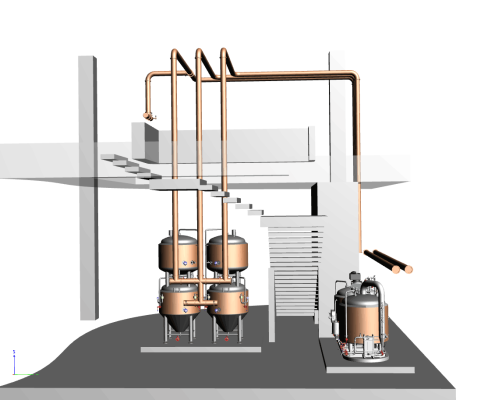

Copper Brewery vessels is another form of brewing equipment, combining brewing and branding, reflecting a different brewing culture.

In most of the brewery equipment,the material of the brew tanks like brewhouse,fermentation tanks or brite beer tanks are alway stainless steel 304.It’s fairly enough for some big industrial brewery project.And it’s also have lower cost for building a new one.However,for microbrewery equipment,if our client have a high-end hotel or pub.YoLong must provide a solution to meet our customer’s the higher demand.

The mainly idea of this is how to make our brewery equipment looks fantastic and let every one who have see them can not forget the beauty and high quality.Using copper to instead the stainless steel is one suitable way. YoLong have the enough experience to make a perfect brewery copper tank.And even can give better suggestion and make progress in building a brewery project.So let’s see how YoLong can do that work.

The change of high end consumption marketing—- From concentration to experience

With the rise of new consumer groups, the original form of product sales with a single brand has been unable to meet the diversified needs of consumers, and “experience” has gradually become a major standard for brands to compete for potential business opportunities.

Diversified consumers not only pay attention to the quality of the product itself, but also pay attention to whether the brand can provide additional high-quality service experience.

For high-end automobile brands, setting up experience stores can not only enrich customers’ experience contacts of brands, shorten the distance between brands and customers by immersive experience, and gradually complete the cultural value output of brands. At the same time, the experience store is also the contact point for brands to understand the consumption needs of diversified customers. In addition, the experience store is an innovative move of brand crossover, which can increase the topic discussion degree of the brand and create a more rich and three-dimensional image for the brand.

Start Today

Restaurant Plus Automobile Culture, create a new one-stop fashion living space

Mercedes me is a new service brand launched by Mercedes Benz in 2014. Mercedes me is different with 4S stores where does not selling cars, but attaching importance to life experience. It is a trendy new life space integrating quality catering, boutique retail, event exhibition, car display and test drive. Now, the first Mercedes Benz Mercedes me experience store in South China officially opened in Shenzhen Vientiane world, which is also the fourth Mercedes me experience store in China and the ninth in the world.

Mercedes Me Chengdu Mercedes Me Shenzhen

“YoLong Brewtech is proud of customizing & manufacturing brewhouse for Mercedes me Chengdu and Shenzhen. It was a challenge to let such big equipment coincide with overall design, we have to finish every details perfectly to make sure brewhouse to be a luxurious and sensitive art which can match up to Mercedes. I am glad to say YoLong did it very well. After the successful experience for two Mercedes me, YoLong Brewtech received a new challenge which is to design and turn key a brewlab for Lamborghini Experience Store in Shenyang. Currently equipment was finished installation and would open this year. It’s interesting that the animal of Lamborghini is ox and this year is Chinese lunar year of ox. ” said by YoLong Brewtech.

ARE YOU HAVE BREWING QUESTIONS?

BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to nano brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- 1:Help expand your recipes.

2:Learn how the Nano brewing system works

3:Convince potential clients that you are on the right track.

4:Be your most reliable “brewery problem solver” partner

5:Make your commercial brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!