Thinking about expansion plan for your brewery? Do it like the pros

/Update October 16, 2022 / By YoLong Brewtech

Start Today

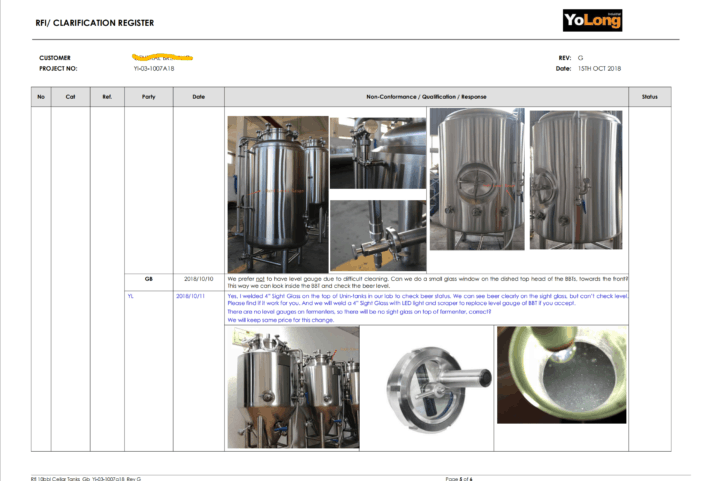

10bbl cellar tanks

With the rapid grow of the craft beer market, more and more microbreweries are considering their expansion plans. It’s a great problem to have for microbrewery or brewpub owners (as demand is increasing), and for us too! But as a brewery equipment supplier, we need to pay more attention as to how to accommodate the future needs of the microbrewery.

Let’s view a project we recently finished of additional 10bbl we installed as part of the expansion plan of a brewery. Hopefully this brewery expansion project can offer some suggestion for any brewery owners who are planning to upgrade their brewery or brewpub.

A. Spend enough time on communication and be patience

We received an inquiry from one client that would like to improve his lauter, increase to four 10bbl fermenters, two brite beer tanks and some accessories for his brewing company.

The client to do/add list included:

- 5bbl Brewhouse

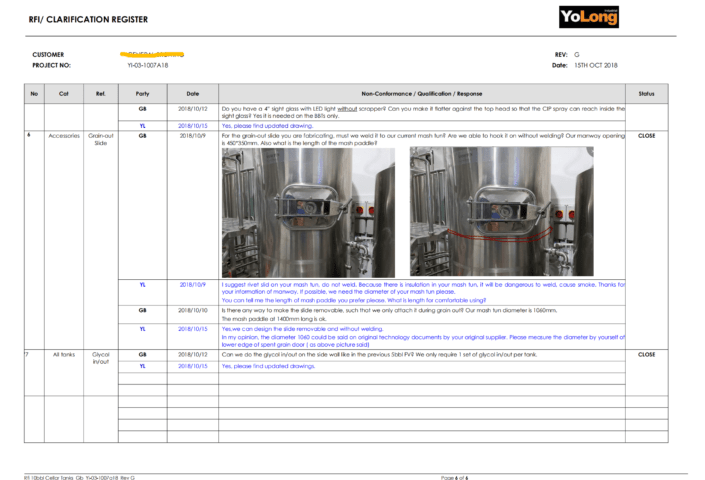

- Add one grain out slide on his lauter tun.

- Add one hops blocker in his kettle.

- Custom fabricate one stainless steel mash paddle for his 5bbl mash tun.

- Cellar Tanks

- Add four 10bbl fermenters

- He has several 5bbl fermenters in his brewery, and in order to keep them all looking good (it can really help with the marketing later on) after installation we designed same level glycol inlet and outlet for the new 10bbl fermenters and existed 5bbl fermenters.

- ladder support

- Hose hooks

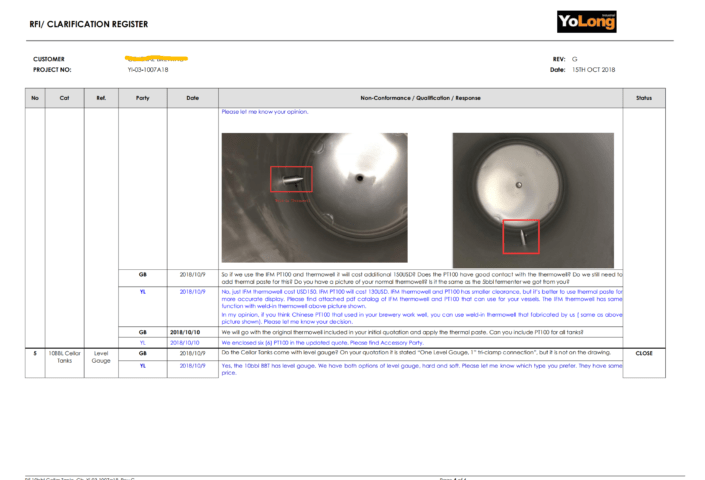

- Accurate size of thermowell

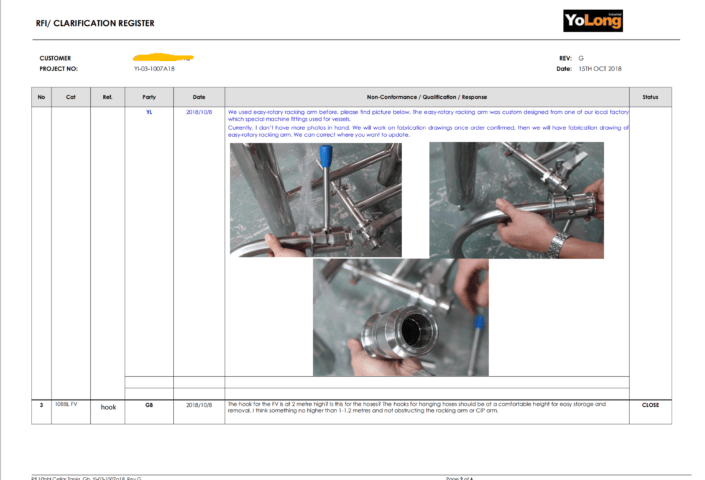

- Rotary racking arm

- Increase two 10bbl BBTs with:

- Same level of glycol outlet (again, to make it nicer)

- Ladder hook

- Electric room dehumidifier

- Add four 10bbl fermenters

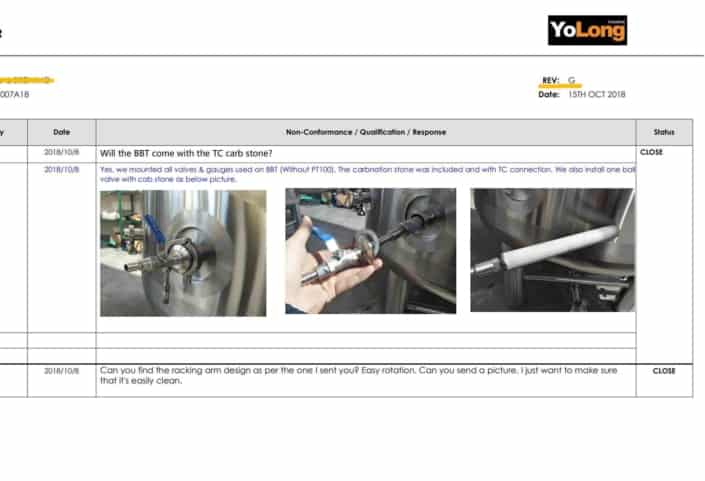

Lots of fittings and accessories were required, such as butterfly valves, sample tap, spunding valves, carb stone, sight glass, Tee, E blow, PT100, etc. We are capable of it and enjoyed this project very much. Transform a small business into a multi-million dollars business gives us a lot of pleasure.

For communication we used a few documents to process everything. Of course emails and phone calls are essential in every brewery expansion project. So be prepared for it.

Things we’re are taking into the account when offering the client a solution:

- What is the surface finish of the existed tanks in the brewery

- What is the layout (pictures required) of the brewery

- Is there enough space or we’re working under limited space in the brewery

- What’s the condition of the existing fermenters and BBTs

- What is the working pressure of tanks

- What is the dimension of all ports of the existing cellar tanks

- What’s the brewer have in mind? Any ideas or specific plans?

B. Strict Project Management

By now, the project manager has finished the big chunk of communication with the client and recorded all details. Project management is very important to make sure we execute the plan exactly how it was intended to be. All the differences that was found and marked by the project manager should be inspected by more people (the draftman, the production director, the inspector etc).

And of course all changes should be photoed and recorded and will be added to the general inspection documents.

1. Jacket and Ports Inspection

2. Jacket Pressure Test With 7bar pressure

3. Ports and Welding Inspection

4. Surface Finish Inspection

5. Tank Pressure Test

C. Purchased parties quality inspection

We carry the responsibility to make sure our products are made in the highest quality, and work well and smoothly.

Going back to our example- The client prefers to use rotary racking arm other suppliers showed him. We tried to find and custom fabricated four rotary racking arms from a new supplier, but we couldn’t promise the quality will be good enough. So we processed the pressure test after receiving the rotary racking arm, and had 3 leakages. Terrible experience. At that point we returned them to supplier for a replacement. After receiving it, we test it again and there was still one faulty rotary racking arm.

However, despite the disappointment from the equipment, the client was very happy to see that we didn’t skip any testing. He said he would have lost three or more tanks of beer if we hadn’t test the workmanship of the other supplier. And eventually he was happy to let us do what we do the best- We changed it to generic racking arms.

D. Packing & Shipment

In order to save the container room, we designed the tanks be packed in stack. Since the the forklift can’t drive through the door (1.7m x 2.3m), we used pallet jack.

Start Today

BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to nano brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- 1:Help expand your recipes.

2:Learn how the Nano brewing system works

3:Convince potential clients that you are on the right track.

4:Be your most reliable “brewery problem solver” partner

5:Make your commercial brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!