What equipment is needed to build a brewery?

/Update October 8, 2022 / By YoLong Brewtech

“What equipment is needed to build a brewery?” This is the question that many owners want to enter the craft brewing industry are concerned about. There are many beer lovers and homebrew all over the world. Some of them are looking to turn their hobby into a business. Others see successful craft breweries and want to be a part of it themselves.

Therefore, this article will help explain the basic equipment needed to set up a commercial brewery.

Start Today

The main equipment is setup a brewhouse system.

The mash+lauter+kettle+whirlpool tank, you maybe need a 2V,3V,4V, even the 5V brewhouse, if you just want to start the micro brewery to start business, and brewhouse capacity is small that 15HL, we suggest that the 2V-MLT+KWPT is a suitable brewhouse choice.

Of course, if your budget and capacity inquiry is bigger, the 3V and 4V is better brewing effiency.

The Brewhouse normally included the follow equipments, The 4V brewhouse as a sample:

- Mash Tun

- SS304 material, Insulation, Steam Jacket for heating , With agitator

- CIP

- Lauter Tun

- SS304 material, Insulation, With rake stir system for loose the grain bed, False milled bottom for lauter process, Wort collect coil and wort grant, Circulation pipes

- CIP

- Spent grain auto-discharge system

- Kettle Tun

- SS304 material, Insulation, Steam Jacket for heating

- CIP

- Over-boil protect unit

- Whirlpool Tun

- SS304 material, Insulation

- CIP

- Tangentialinlet

- The sloping bottom

- Brewhouse workdeck, wort/CIP pipes, steam pipes etc.

- Brewhouse control system

- Control the brewhouse temp

- Control all the agitator

- Control all the pump, transfer

- Etc

The mash tun is where you mix the water and malt that will turn starch into sugar

The lauter tun is the vessel where you transfer you sugar liquid (wort) from; going to the brew kettle leaving the malt behind.

The brew kettle is where you boil your liquid, sterilizing it, there is a color change and also where you add the hops that give you beer bitterness.

The whirlpool is a vessel where you create centrifugal forces to create a cone of matter to be left behind when you collect your wort to the fermentation vessel.

Water treatment and supply system

The brewery need the clean water for brewery, so the most tap water can not use as brew water directly, so it will need the RO filter systen to offer the stable clean water for the brewery.

The RO water system.

- Filter

- Pure water stock tank

- Supply pump

The Hot water system

- Hot water tank, the capacity will double of the brewhouse

- Water supply pump

- Steam pipes connected for heating the water

The cold water system

- cold water tank, the capacity will double of the brewhouse

- Water supply pump

- Glycol pipes connected for cooling the water

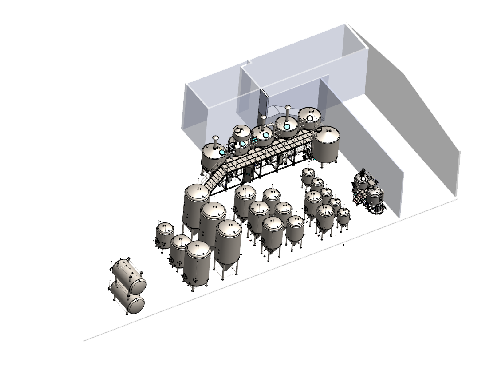

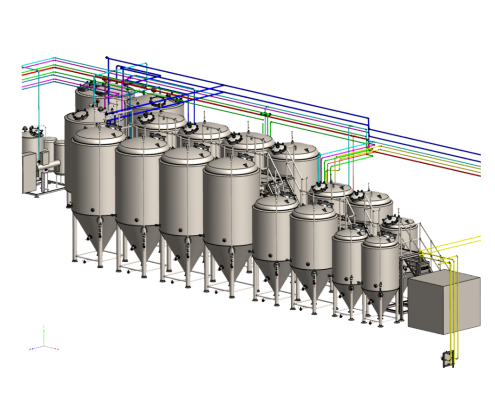

Brewhouse Cellar System

- Fermenter

Most breweries have uni-tanks. These tanks are for the fermentation and maturation of the beer.

You ferment the beer, then cool it to drop the yeast to the bottom of the tank. Then dump or save the excess yeast for the next brew.

The beer is stored in the tank until it’s ready with a little bit of yeast still in suspension. For ale it may be a few days or for lager it can be 28 days.

- The bright tank

A brighter beer tank is for the clear beer to be sent to after fermentation. It’s the tank where you package the beer from. You can clear the beer a number of ways from fining, filtering or with a centrifuge.

- The Cellar Control System

Control the glycol cooling work for the fermenter and bright tank

The temp automatic control

- The Glycol Supply System

- Industrial Chiller

- Glycol supply/circulation pump

- glycol pipes connected to fermenter and bright tank

When you brew beer, temperatures are very important. The way you control temperature is with a glycol system. This is a tank of cold glycol that has its own pipe work to pump cold glycol (around -3 to 4C) to where it is needed.

So, for example FV’s have a “cooling Jacket” they have an inner tank wall and a cavity that has houses insulation and also glycol pipework.

The glycol goes through this pipework and can cool the FV down when it gets hotter during fermentation. The glycol doesn’t come into contact with the beer as it is inside the glycol pipework between the FV inner and outer walls.

- The Steam Supply System

- Industrial Boiler

- steam pipes connected to brewhouse and hot water tank

- The other accessory equipments

- The malt mill, auger and conveyor as option.

- CIP station-2V-4V

- Portable transfer pump cart

- Keg Washer/Filler

- Bottle Filler

- Bottle Washer

- Bottle/Can label machine

- Yeast brink

- Transfer Hose

Start Today

BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to nano brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- 1:Help expand your recipes.

2:Learn how the Nano brewing system works

3:Convince potential clients that you are on the right track.

4:Be your most reliable “brewery problem solver” partner

5:Make your commercial brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!