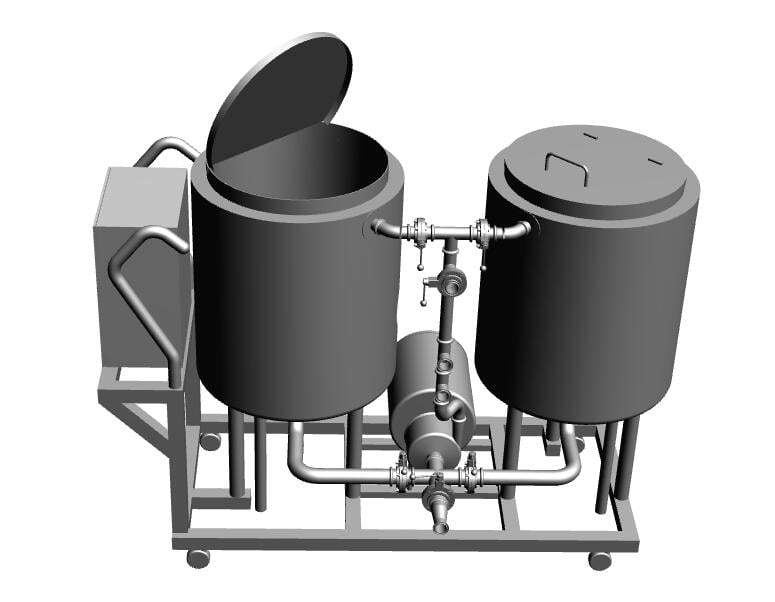

Portable CIP

If you want to know more about what is a portable CIP and what are its applications in a brewery, we have all the answers for you right here. CIP stands for Clean-In-Place and just like every other beverage production company, breweries rank cleanliness with equal importance to product quality.

It doesn’t matter if you brew beer at home or as a craft or commercial beer company: your reputation stands on the line every time someone drinks your product. The best and easiest way to ensure your beer is delicious and drinkable, you have to have a thorough, systematic, and consistent cleaning routine in place.

cip skid,brewery

cip skid,brewery 50L CIP

50L CIP CIP panel

CIP panel elements

elements portable CIP

portable CIP clean in place brewery

clean in place brewery cabinet

cabinet electric heating tube

electric heating tube

What Makes a Successful CIP Program?

Cleaning in place or CIP is when a systematic process of cleaning your professional brewing equipment occurs with the need to disassemble your setup. CIP has huge benefits over manual cleaning methods (although traditional manual cleaning is fine for homebrew setups).

Cleaning brewery equipment eliminates the possibility of human error or neglect. It has become brewery industry standard practice because not only does it save on intensive labor and the potential to be exposed to excoriating chemicals, but it also saves on the cost of chemicals.

Advantages of CIP

When used correctly, CIP cleaning agents reduce the surface tension of water which makes it easier for cleaning solutions to penetrate every surface. Even without the recommended chemical additives, a CIP system still achieves a reasonable level production safety and cleanliness due to the amount of time, the action of the equipment, and the temperature.

A Clean-in-Place system uses holding tanks to store the cleaning chemicals. When needed, the CIP can manually or automatically pump out the chemicals from the storage tanks straight into the tanks that require cleaning.

A spray ball is the device used to coat the tank interior with cleaning chemicals. When the job is completed, the chemicals are pumped out back into the storage tank for reuse. This cycle can be repeated several times before the need for new chemicals arises. Water is then sprayed into the tank interior for thorough rinsing.

Typically, a brewery CIP cycle will involve the following functions.

Why the YoLong team place such emphasis on the smooth finish of tank interiors and welds is because this guarantees there is no place for soil to embed itself or hide from the CIP spray ball. After Cleaning-in-Place, your brewery setup is ready for another batch of delicious beer to be made.

If you require a different CIP system, please contact our customer service to discuss your needs.

Portable CIP Skid specifications

| Specification Item | Details / Description | Additional Notes |

|---|---|---|

| Capacity | 50L to 150L | Various options available |

| Electric Control | Electric panel for temperature | Precise control during cleaning |

| Construction Material | Stainless Steel 304 (SS 304) | Durable and corrosion resistant |

| Pump | One pump included | For fluid circulation |

| Lid | Top removable lid | Easy access for maintenance |

| Heating Element | Heating tube | Supports temperature regulation |

| Temperature Monitoring | Temperature gauge | For accurate heat tracking |

| Insulation | Mineral wool insulation | Improves thermal efficiency |

| Internal Surface Finish | 2B finish inside | Smooth and cleanable |

| External Surface Finish | #4 finish outside | Brushed stainless steel look |

| Weld Finish | Inside and outside welds polished to #4 | Sanitary and aesthetic |