How to recycle the yeast of the brewery ?

In brew industry the water, hops, malt are the consumptions of disposables except for yeast, Not only will help save the cost also be beneficial for other business developments, Certainly that will be depend on is this kind of yeast will be deserve able to recycle….

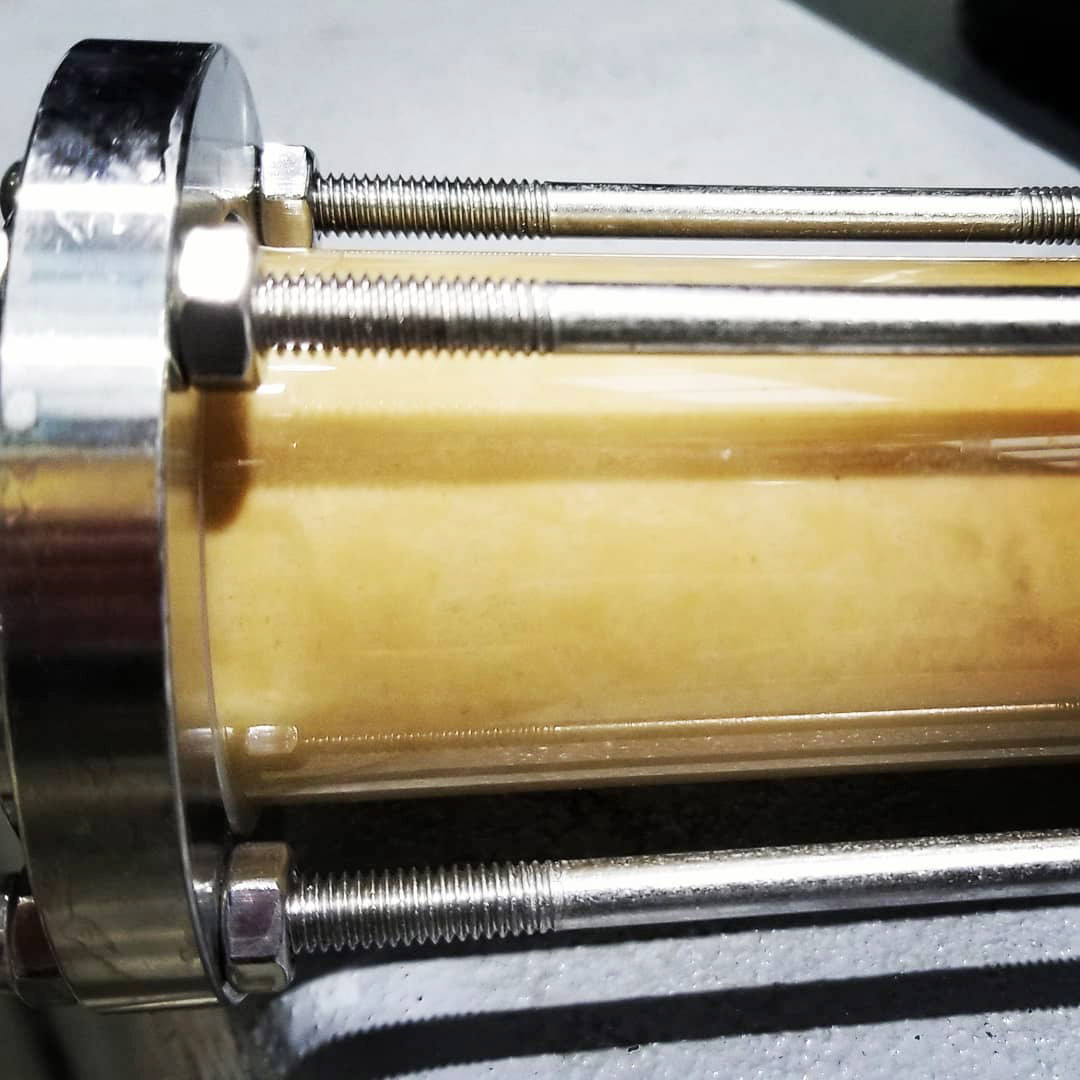

The ideal recycle time is the 1 – 2 days after beer cold crash and what part of yeast we should recycle is the middle layer and means the amount we can acquire could up to 60-75%.

< Top layer includes too much protein and impurities and the bottom layer includes too much dead cells.>

We can confirm if the yeast could be still using for follow brews by following characteristics:-

Appearance: Looks purity with fresh surface & flavour, Firmly but not sticky

If the color is dark, it means that the wort filtration quality is poor, or the cold and hot coagulates are not discharged completely; the yeast mud is thin and thick, in general, the middle yeast mud discharged should be thick, if it is thin, it may be contaminated with bacteria.

Smell and taste: It should have an inherent yeasty taste, without bitterness, sourness and other peculiar smells.

Microscopic examination of yeast mud.

Microscopically examined yeast should be neat, plump and shiny, with thin cell walls, small vacuoles, inconspicuous contents, and no abnormal cells: Yeast cell activity is more than 95%~97% (0.1% methylene blue) The cells were stained in dark blue, and the cells were less than 3%~5%); the storage time in cold water (1~2℃) should not exceed 3 days.

A few points to note when recycling yeast:

- Yeast is very sensitive to the accumulation of CO2, so the yeast should be recovered in time;

- Usually fresh yeast can be used for 6 generations, and it is recommended to use no more than 4 generations for craft beer;

- Washing and sieving reduces yeast activity and also brings the risk of microbial infection. Yeast washing and sieving should be abandoned as much as possible;

- The fermentation performance of brewer’s yeast in the previous round of production was normal, such as hypoglycemia, diacetyl reduction, fermentation degree and brewer’s yeast sedimentation.

- Yeast should be re-added as quickly as possible. If the yeast is only stored for 2-3 hours, it is not necessary to cool it. During the shutdown period, yeast should also be stored at low temperature (0°C) in a certain concentration of beer or wort.

The usage rate of brewer’s yeast is generally not more than 5 generations, and craft beer is usually used for 4 times. Therefore, learning to recycle brewer’s yeast can reduce costs accordingly and improve your brewing level.

In addition, although the discarded yeast is no longer used in the brewing process of beer, it can be used in other aspects. The yeast cell contains almost no fat, starch and sugar, but contains excellent protein, complete B vitamins, a variety of Bio-minerals and high-quality dietary fiber. “Three low and four excellent” is a high-level summary of its nutritional characteristics: low-fat, low-sugar, low-calorie (no cholesterol), high-quality complete protein (containing 8 essential amino acids), complete B vitamins, 14 kinds of High-quality minerals and high-quality functional dietary fibers in the combined state of life. Various nutrients extracted from it are widely used in food processing, health care, biopharmaceutical industry and feed industry, and have broad prospects. The utilization and development of brewer’s yeast mud can not only reduce pollution and resource waste, but also generate additional economic benefits.

BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to nano brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- Help expand your recipes.

- Learn how the Komhucha brewing system works

- Convince potential clients that you are on the right track.

- Be your most reliable “brewery problem solver” partner

- Make your commercial Kombucha brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

Frequently Asked Questions (FAQ)

1) When is the best time to harvest yeast in a brewery?

- Harvest 24–48 hours after crash-cooling when the cone has stratified. Collect the dense, creamy middle layer; discard the top (proteins/foam) and bottom (dead cells/trub).

2) How many generations can I safely repitch ale yeast?

- Many breweries target 4–6 generations for consistent flavor. Track performance (attenuation, VDK, flocculation) and retire the crop if deviations or contamination occur.

3) What cell counts and viability should I aim for when repitching?

- Typical pitch for ales: 0.5–1.0 million cells/mL/°P; lagers: 1.0–1.5 million. Aim for ≥90–95% viability (methylene blue or methylene violet) when pitching.

4) How should harvested yeast be stored before reuse?

- Store cold at 0–2°C in sanitized brink under slight CO2 pressure, with periodic gentle agitation. Use within 72 hours; sooner is better to limit glycogen depletion.

5) Should I wash or rinse yeast with water?

- Generally no. Washing reduces viability and invites contamination. Prefer clean harvest and immediate reuse. If clarification is essential, use sterile isotonic wort and strict asepsis.

2025 Industry Trends in Brewery Yeast Recovery

- Data-driven repitching: small breweries adopt affordable cell counters and pH/VDK monitoring to qualify yeast crops batch-by-batch.

- Oxygen-conscious handling: low-oxygen transfers and CO2-blanketed brinks to maintain viability and reduce staling precursors.

- Strain-specific programs: tailored generation limits and cone harvest heights per strain (e.g., hazy ale vs. lager) to stabilize sensory.

- Sustainability KPIs: tracking repitch rate, crop utilization %, and lab-confirmed viability as cost and waste reduction metrics.

- Microbiome screening: periodic plating or PCR screens to detect wild yeast/bacteria creep in multi-generation programs.

Yeast Harvest & Repitch Benchmarks (2024–2025)

| Metric | Typical Range | 2025 Best Practice Target | Notes / Sources |

|---|---|---|---|

| Harvest window post-crash | 1–3 days | 24–48 hours | Best middle-layer purity |

| Viability at pitch | 85–95% | ≥90–95% | Methylene blue/violet; Trypan blue |

| Generations (craft ales) | 3–8 | 4–6 | Retire on sensory/QA drift |

| Storage time before pitch | 0–5 days | ≤72 hours | 0–2°C, CO2 blanket |

| Pitch rate (cells/mL/°P) | 0.5–1.5M | Ales 0.75–1.0M; Lagers 1.25–1.5M | ASBC yeast guidance |

| Contamination threshold | <10^3 CFU/mL | “None detected” on routine plates | ASBC Micro methods |

Authoritative sources:

- ASBC Methods of Analysis (Yeast-4C, Micro): https://www.asbcnet.org/

- Brewers Association QA and yeast handling best practices: https://www.brewersassociation.org/

- White Labs/Wyeast technical notes on pitch rates and repitching: https://www.whitelabs.com/ and https://wyeastlab.com/

Latest Research Cases

Case Study 1: Cone Harvest Optimization Improves Consistency (2025)

Background: A 15 bbl brewery saw drifting attenuation and diacetyl spikes by generation 5–6 in a flagship pale ale.

Solution: Standardized crash protocol, timed harvest at 36 hours, collected only 30–60% of cone slurry (middle fraction), implemented bench viability counts and VDK checks before repitch.

Results: Apparent attenuation variance dropped from ±2.2% to ±0.7%; diacetyl holds decreased by 80%; usable generations stabilized at 6 with no sensory defects.

Case Study 2: Cold Storage and CO2-Blanketed Yeast Brink (2024)

Background: Repitch viability fell below 85% after weekend holds, causing slow starts and ester variability.

Solution: Added insulated 1 hL brink with 0–2°C glycol jacket, CO2 headspace purge, and gentle recirc prior to pitch; reduced average hold to 48 hours.

Results: Mean viability at pitch increased to 93–96%; first 24-hour gravity drop improved by 15–20%; reduced need for dry yeast supplementation, saving ~$2,400/quarter.

Expert Opinions

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

“Harvest the right fraction and measure what matters—viability, VDK, and attenuation. Quantifying the yeast crop transforms repitching from art into repeatable practice.” - Chris White, Founder, White Labs

“Healthy yeast starts with proper pitch rates and storage. Keep it cold, limit oxygen, and repitch quickly to maintain glycogen reserves and performance.” - Ashton Lewis, Technical Support Director, BSG

“Consistency in your yeast program—standard harvest timing, sanitation, and lab checks—pays back in fewer stuck ferments and tighter flavor windows.”

Practical Tools/Resources

- ASBC Methods (yeast viability, microbiology): https://www.asbcnet.org/

- Brewers Association Quality Manual (cellar and yeast handling): https://www.brewersassociation.org/

- Keg/yeast brink hardware and CIP guidelines from vendors (GEA, Pentair, Alfa Laval)

- Affordable lab tools: hemocytometers or automated cell counters, methylene blue/violet kits, VDK (diacetyl) test protocols

- White Labs and Wyeast pitch rate calculators and strain-specific repitch advice

Last updated: 2025-08-29

Changelog: Added 5 yeast-recycling FAQs, 2025 trends with benchmark table, two case studies on cone harvest optimization and cold storage brinks, expert viewpoints, and practical QA resources for brewery yeast programs.

Next review date & triggers: 2026-02-28 or earlier if ASBC/BA update yeast handling methods, contamination rates rise above thresholds, or average viability at pitch falls below 90%.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?