How to configure CIP for your brewhouse

To clean microbrewery equipment—especially the brewhouse—CIP equipment and pipelines should be properly configured. When designing a CIP system, key factors to consider include ease of operation, cleaning efficiency, and cost.

Below are some tips for configuring your CIP system based on brewhouse size and automation level:

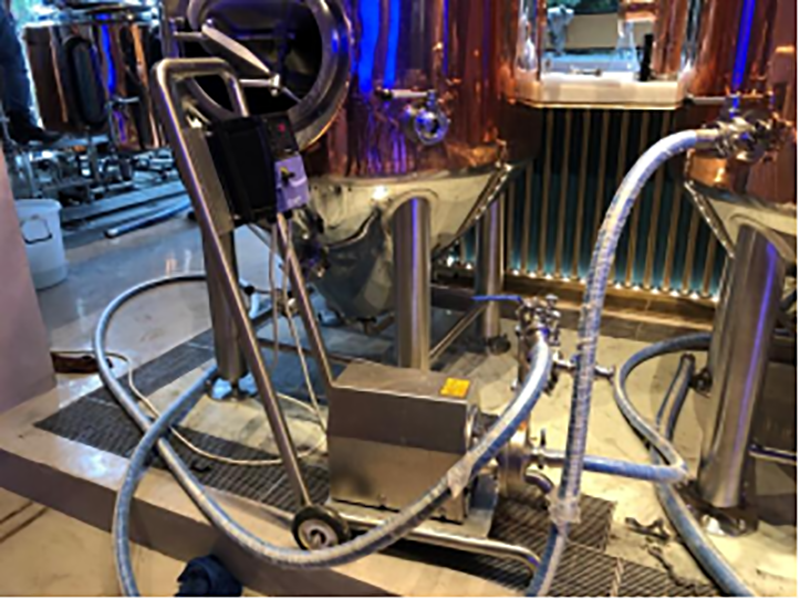

1. Use a Portable Pump as a CIP Cart

This option is suitable for brewpubs or microbreweries with brewhouse sizes below 5 BBL and low brewing activity.

- Use the boil kettle as a CIP tank to mix CIP liquid.

- Use the portable pump as a CIP pump to clean the brewhouse and cellar tanks.

Pros:

- Saves money

- Saves space

- Easy to move

Cons:

- Cannot brew while the boil kettle is being used for CIP liquid mixing

- Requires deep cleaning of the boil kettle after mixing CIP liquid

- Risk of boil kettle damage after long-term usage

2. How to Configure CIP Pipelines When CIP Cart is Available

A CIP cart is suitable for microbreweries with brewhouse sizes above 5 BBL and high brewing activity. The CIP cart can function as a CIP station and is a cost-effective solution.

1) Simple Manual Brewhouse with 2V Combination

For a simple manual brewhouse, especially those below 10 BBL in size, a basic CIP arm configuration is recommended. In this setup:

- A single CIP arm is installed on the tank.

- Hoses are used as temporary CIP supply and return pipelines.

This setup is cost-saving but requires more manual labor and poses a risk of injury during frequent valve and hose connections or disconnections.

2) Semi-Auto Brewhouse with 3V/4V Combination or More

For semi-automatic brewhouses with a 3V/4V combination or larger, integrated CIP pipelines are recommended. In this configuration:

- CIP supply and return pipelines are permanently installed and connected to a valve panel.

- During cleaning, the brewer simply operates the valves to CIP each brewhouse vessel without repeatedly connecting or disconnecting hoses.

This design significantly reduces labor and simplifies the CIP process, with only a slight increase in investment.

3) High-Automation Brewhouse with 3V/4V Combination or More

For a highly automated brewhouse with a 3V/4V combination or larger, integrated CIP pipelines are strongly recommended. This configuration includes:

- Fully automatic CIP valves

- Specialized CIP pump

- RO water pipelines and HLT pipelines connected with CIP pipelines

This setup enables a full-automatic CIP process, ensuring:

- Complete sanitation

- No dead space

- No mixing of CIP liquid with wort or water

- Minimal manual intervention to avoid operational errors

Although the initial investment is higher, the benefits are significant, including improved safety, efficiency, and reduced risk of contamination or human error.

For any other enquiry you may have, please search and read our FAQ section. If you still haven’t found what you are looking for, our support team is always ready with an answer at [email protected], now also available on WhatsApp.

Frequently Asked Questions (FAQ)

- Q1: What CIP cycle parameters are recommended for brewhouse vessels?

A1: Typical ranges: pre-rinse 5–10 min at ambient–40°C; caustic wash 20–40 min at 1.5–3.0% NaOH at 60–75°C; intermediate rinse to conductivity endpoint; acid wash 10–20 min at 0.5–1.0% nitric/phosphoric at 40–60°C (as needed); final rinse and 0.1–0.2% peracetic acid (PAA) sanitize 5–10 min, drain to dry. - Q2: How do I size a CIP pump for effective spray coverage?

A2: Match pump flow/pressure to spray device spec. For static spray balls, target 1.5–2.5 m/s line velocity and 1.5–2.0 bar at the ball; for rotary jet devices, 6–10 bar with adequate flow (often 7–15 m³/h per head). Maintain turbulent return (Re > 4000) in lines. - Q3: Can I reuse CIP solutions to cut cost without risking hygiene?

A3: Yes, with controls. Reuse caustic until conductivity, soil load (COD), or pH falls below setpoints; filter particulates (bag filters 50–100 µm), monitor temperature, and cap reuse cycles (e.g., 5–10 turns). Never reuse final sanitizer; verify with ATP or micro swabs. - Q4: How do I prevent cross-contamination between CIP and product lines?

A4: Use double-seat mix-proof valves or physical breaks, dedicated CIP headers, non-return valves on CIP returns, hard interlocks (PLC) that block product transfer when CIP active, and valve seat-lift cleaning routines. - Q5: What validation proves my CIP is effective?

A5: Combine measurable endpoints: conductivity and temperature curves, contact time logs, flow/pressure at spray head, visual inspections of shadow areas, ATP bioluminescence (<10–30 RLU targets depending on site), and periodic micro testing (swab/rinse).

2025 Industry Trends: CIP

- Heat and water minimization: Wider adoption of heat recovery on CIP return and smart rinse-to-endpoint control to cut water 20–35%.

- Sensor-driven verification: Inline conductivity, temperature, turbidity, and pressure at the spray device logged to SCADA/MES for audit trails.

- Safer chemistries: Optimized PAA dosing with real-time ppm monitoring; reduced nitric usage in favor of blended acids to protect stainless and drains.

- Automation and interoperability: OPC UA/MQTT data models standard in new skid controls; recipe-based CIP with QR-coded vessels.

- Hygiene by design: Tanks specified with validated drainability (<15 min to 99.5% empty), weld Ra ≤ 0.8 µm, and removable shadow-creating internals.

2025 CIP Benchmarks and Cost/Performance Signals

| KPI | 2021 Baseline (typical) | 2025 Target/Best-in-Class | Why it Matters | Sources |

|---|---|---|---|---|

| Water per CIP cycle (brewhouse vessel) | 400–700 L | 250–450 L | Endpoint rinsing saves water | Brewers Association sustainability; MBAA TQ |

| Caustic concentration (NaOH) | 2.0–3.0% | 1.5–2.5% with heat | Lower chem with better temp/flow | ASBC Sanitation resources |

| Caustic temp | 50–60°C | 60–75°C | Higher temp → faster soil removal | MBAA Best Practices |

| Energy per CIP cycle | 8–14 kWh | 5–9 kWh with heat recovery | OPEX reduction | DOE Better Plants |

| ATP RLU post-CIP target | <50–100 RLU | <10–30 RLU | Verifies hygiene quickly | AHA/MBAA guidance |

| CIP cycle time (vessel) | 90–120 min | 55–85 min | Throughput and tank availability | Vendor FAT/SAT data |

Selected references: Brewers Association — https://www.brewersassociation.org; MBAA Technical Quarterly — https://www.mbaa.com; ASBC Methods — https://www.asbcnet.org; U.S. DOE Better Plants — https://www.energy.gov

Latest Research Cases

Case Study 1: Endpoint-Controlled Rinses Cut Water and Time (2025)

Background: A 30 bbl brewhouse used fixed-time rinses, high water, and long tank downtime.

Solution: Added inline conductivity and turbidity sensors with PLC logic to terminate rinses at endpoint; upgraded spray balls and insulated CIP lines.

Results: Water per cycle reduced 32%; average CIP time per vessel cut by 22 minutes; annual utility savings ~$9,800; no increase in micro fails over 6 months.

Case Study 2: Heat Recovery on CIP Return Lowers Energy (2024)

Background: Rising steam costs made hot caustic cycles expensive.

Solution: Installed plate heat exchanger to reclaim heat from hot CIP return to preheat incoming rinse and make-up solutions; added chem reuse with filtration.

Results: CIP energy intensity down 28%; caustic make-up reduced 15% via reuse; payback in 18 months; stainless surface inspection showed no corrosion increase.

Expert Opinions

- Mary Pellettieri, Brewing Quality Consultant; Author, “Quality Management for Breweries”

Viewpoint: “Validate CIP with measurable endpoints—conductivity, temperature, and ATP—not just time. Hygienic design and verification prevent chronic flavor issues.” - Dr. Tom Shellhammer, Professor, Oregon State University

Viewpoint: “Residues and oxygen exposure compound flavor instability. Effective CIP paired with closed transfers meaningfully extends shelf life.” - John Blichmann, Founder, Blichmann Engineering

Viewpoint: “Good spray coverage and pump sizing beat brute-force chemistry. Design CIP for flow, pressure, and drainability first.”

Practical Tools/Resources

- Brewers Association: CIP and sustainability toolkits — https://www.brewersassociation.org

- MBAA Best Practices & Technical Quarterly — https://www.mbaa.com

- ASBC Methods (sanitation, microbiology) — https://www.asbcnet.org

- EHEDG & 3-A sanitary design guidance — https://www.ehedg.org | https://www.3-a.org

- DOE Better Plants (heat recovery, insulation) — https://www.energy.gov

- OPC Foundation (OPC UA specs for skid integration) — https://opcfoundation.org

Last updated: 2025-09-01

Changelog: Added 5 focused CIP FAQs; introduced 2025 trends with benchmark table; provided two case studies on endpoint rinsing and heat recovery; included expert viewpoints and practical resources

Next review date & triggers: 2026-02-15 or earlier if BA/MBAA sanitation guidance updates, new OPC UA profiles for CIP skids release, or significant chemical safety regulations change

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?