How to choose beer brewing equipment?

What are some typical questions when setup a brewery? looking more closely at equipment needs. Brewhouses are all different, but certain questions can be applied to the majority of brewing projects.

By this point we know the size of brewhouse needed, number of beers to brew, styles for the core range and what pack types will be used. It’s then a case of tailoring the equipment list to the particular needs of the project.

If it is homebrew, there are three ways to choose from: brewing box brewing, malt leaching brewing and whole malt brewing.

Brewing box brewing: Just mix the syrup fluid and water, and can make a barrel of beer quickly after fermentation. Simple operation, only a simple brewing equipment can be completed, such as a fermented barrel (can be supplied), a specific gravity, a tube, a siphon, a stirring spoon, a thermometer, a pressure barrel, and brewing kettle.

Malt leaching brewing: Malt leaching is required to be added to water. According to the type of beer, the paste is added to the batch, and the obtained wheat sauce will be cooled and transferred to the fermentation barrel. The required equipment is a little bit more, such as the fermenter (configurable air plug), specific gravity, tube, siphon, stirring spoon, thermometer, pressure barrel, boiled pot, said, timer, cooling coil, or refrigerator If you need to add a special cereal, you need a cereal bag.

Narutomal malt Brewing: The Mash Tun, Lauter Tun, Kettle, Yeast activation, fermentation, BBT. More equipment, techniques, and knowledge are needed. Such as: boiling pot, called, thermal insulation pot (bottom water valve), stirring spoon, washing tube, cooling coil, measure cup, fermenter, tube, specific gravity, pressure barrel, a small malt mill. etc. . .

If it is plan to open a brewery, you need to consider:

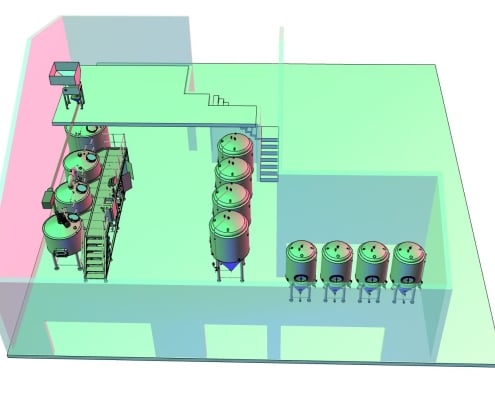

Relative to Home Brewing, a complete equipment requires some equipment to complete the entire brewing and fermentation process: malt meter, malt crushing, Mash Tun, Lauter Tun, Kettle / WhirlPool, Plate heat exchanger, oxygenating device, fermenter, BBT , CIP, hot water tank or water heater, refrigerator, GWT, KEG, gas cylinder, refrigerator, steam boiler (optional), air compressor (optional), etc.

What Automation do you Need For your brewery?

One of the first steps is deciding how much automation is required for the project. Automation costs money so depending on the overall budget, there could be need to prioritize a few key areas.

Here are some of main areas where automation is used in craft beer brewing:

- Control mash and sparge water temperature and volumes

- Setting the wort collection temperature so it automatically adjusts itself on collection to FV.

- Foam sensor to cut off of boil so avoiding boil overs and automatic temperature set for the brew kettle.

- Control for rake speed and height

- Inline flowmeter from the lauter to the kettle, with screen readout and volume set.

- Mash tun temperature control and recipe input for automatic step mashing

- Wort speed control from lauter to kettle

The above list are the key areas I highlight, when a clients ask about automation. They’ll help improve beer quality, brewhouse safety and are not so expensive. Depending on the budget, we can prioritize where automation is best used to fit a particular project needs.

According to the actual situation of the steam, gas and electricity of the site. Select a suitable heating method.

Are you having brew questions?

We can help!

There are so many variables to consider when open a brewery. You need to be methodical in your planning. So after I’ve asked my initial starting a brewery questions, covering the above issues in follow-up discussions allows us to begin putting an equipment list together.

Every project has a budget, so, when opening a brewery,Understanding the fund budget is an important prerequisite for successfully opening a brewery. In this way, we can choose the right brewing target and equipment according to the situation at the beginning.

YoLong Brewtech has been engaged in consulting, design and manufacture of professional beer brewing equipment since 2004. And are actively sharing our expertise on more brewing and equipment. If you have any questions or requirements about brewing equipment, you can contact our professional technical engineers to find the answer.

Estimating the cost of brewery equipment

From equipment costs to brewery size, construction costs and licensing, brewery operating costs can vary widely depending on your specific operation.

When estimating the price of your investment, We have Multiple types of equipment are available as well as brewery equipment financing options to help you start up and running.

- Nano Brewery Equipment (1BBL-5BBL)

- Brewpub Brewing Equipment(5BBL-10BBL)

- Microbrewery Equipment (10BBL-20BBL)

- Commercial Brewery Equipment(20BBL-50BBL)

Contact us to learn more about of brewing equipment or submit a request for brewery pricing using the button below.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!