How to choose beer brewing equipment?

What are some typical questions when setup a brewery? looking more closely at equipment needs. Brewhouses are all different, but certain questions can be applied to the majority of brewing projects.

By this point we know the size of brewhouse needed, number of beers to brew, styles for the core range and what pack types will be used. It’s then a case of tailoring the equipment list to the particular needs of the project.

First, it is necessary to determine that

Home brewing?

If it is homebrew, there are three ways to choose from: brewing box brewing, malt leaching brewing and whole malt brewing.

Brewing box brewing: Just mix the syrup fluid and water, and can make a barrel of beer quickly after fermentation. Simple operation, only a simple brewing equipment can be completed, such as a fermented barrel (can be supplied), a specific gravity, a tube, a siphon, a stirring spoon, a thermometer, a pressure barrel, and brewing kettle.

Malt leaching brewing: Malt leaching is required to be added to water. According to the type of beer, the paste is added to the batch, and the obtained wheat sauce will be cooled and transferred to the fermentation barrel. The required equipment is a little bit more, such as the fermenter (configurable air plug), specific gravity, tube, siphon, stirring spoon, thermometer, pressure barrel, boiled pot, said, timer, cooling coil, or refrigerator If you need to add a special cereal, you need a cereal bag.

Narutomal malt Brewing: The Mash Tun, Lauter Tun, Kettle, Yeast activation, fermentation, BBT. More equipment, techniques, and knowledge are needed. Such as: boiling pot, called, thermal insulation pot (bottom water valve), stirring spoon, washing tube, cooling coil, measure cup, fermenter, tube, specific gravity, pressure barrel, a small malt mill. etc..

If it is plan to open a brewery, you need to consider:

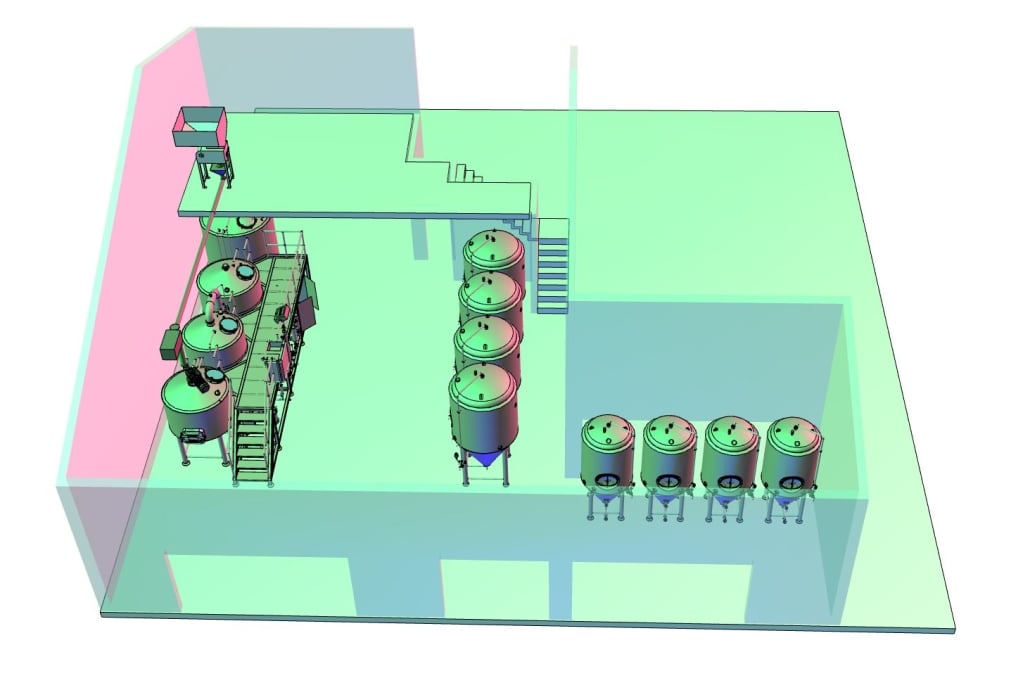

Relative to Home Brewing, complete equipment requires some equipment to complete the entire brewing and fermentation process: malt meter, malt crushing, Mash Tun, Lauter Tun, Kettle / WhirlPool, Plate heat exchanger, oxygenating device, fermenter, BBT, CIP, hot water tank or water heater, refrigerator, GWT, KEG, gas cylinder, refrigerator, steam boiler (optional), air compressor (optional), etc.

What Automation do you Need For your brewery?

One of the first steps is deciding how much automation is required for the project. Automation costs money so depending on the overall budget, there could be need to prioritize a few key areas.

Here are some of main areas where automation is used in craft beer brewing:

- Control mash and sparge water temperature and volumes

- Setting the wort collection temperature so it automatically adjusts itself on collection to FV.

- Foam sensor to cut off of boil so avoiding boil overs and automatic temperature set for the brew kettle.

- Control for rake speed and height

- Inline flowmeter from the lauter to the kettle, with screen readout and volume set.

- Mash tun temperature control and recipe input for automatic step mashing

- Wort speed control from lauter to kettle

The above list are the key areas I highlight, when a client ask about automation. They’ll help improve beer quality, brewhouse safety and are not so expensive. Depending on the budget, we can prioritize where automation is best used to fit a particular project needs.

According to the actual situation of the steam, gas and electricity of the site. Select a suitable heating method.

Frequently Asked Questions (FAQ)

1) How do I right-size beer brewing equipment for projected demand?

- Translate annual volume into weekly brewdays and turns. Aim for 4–6x brewhouse volume in cellar tanks, with a mix of 1× and 2× FVs for double-batching core beers.

2) Which heating method should I choose: steam, direct fire, or electric?

- Steam offers fastest ramp and even heat for multi-vessel systems; electric is cleaner for small/urban sites with sufficient power; direct fire lowers capex but needs strong ventilation and combustion controls.

3) What automation delivers the best ROI on a tight budget?

- PID temperature control, lauter rake/flow control, inline flowmeter to the kettle, basic batch logging, foam/boil-over sensors, and CIP endpoint verification via conductivity.

4) How should water treatment be handled for consistent beer quality?

- Start with sediment + carbon filtration; add RO with blending for style targets. Confirm chlorine/chloramine removal and maintain a water spec sheet tied to each recipe.

5) What are the “must-have” utilities before ordering beer brewing equipment?

- 3‑phase power (or adequate single-phase), steam or electric capacity, glycol chiller sized for concurrent fermentations and crash, floor drains, make-up air/venting, compressed air, CO2/N2, and data drops for controls.

2025 Industry Trends for Beer Brewing Equipment

- Semi-automation becomes standard: PLC/HMI, recipe libraries, interlocked valves, and inline sensors (gravity, DO) for small teams.

- Sustainability first: heat recovery to HLT, VFDs on pumps, thicker insulation, target water-to-beer ≤4.0 hL/hL.

- Modular scaling: smaller hot sides feeding larger unitanks and mobile canning to grow without replacing brewhouse.

- Low-DO practices: closed transfers, CO2 purged lines, and spunding to extend hop aroma shelf life.

- Compliance and traceability: QR-linked weld maps/material certs, improved FAT documentation to reduce commissioning risk.

2025 Benchmarks and Stats

| Metric | Typical Range/Benchmark (2025) | Notes / Source |

|---|---|---|

| Turnkey brewhouse (5–20 BBL, semi-auto) | $60,000–$300,000 | Aggregated OEM quotes 2024–2025 |

| Complete startup (hot side + cellar + glycol) | $150,000–$700,000 | Vendor estimates 2025 |

| Water-to-beer ratio (hL/hL) | 3.0–5.0 attainable; best-in-class <3.5 | Brewers Association Sustainability |

| Hot-side energy intensity | 10–22 kWh-eq/BBL | U.S. DOE AMO guidance |

| Brewhouse efficiency | 82–92% | Milling, mash/lauter control dependent |

| Packaged DO best practice | <50 ppb | ASBC/MBAA guidance |

| Custom tank lead time | 10–24 weeks | Vendor reports 2025 |

Selected references:

- Brewers Association research and sustainability tools: https://www.brewersassociation.org/industry/research

- ASBC Methods of Analysis (DO, VDK, pH): https://www.asbcnet.org

- Master Brewers Association of the Americas (MBAA): https://www.mbaa.com

- U.S. DOE Advanced Manufacturing Office tools: https://www.energy.gov/eere/amo/tools

Latest Research Cases

Case Study 1: Automation-First Upgrade for Consistency (2025)

Background: A 7 BBL brewpub faced OG variability and long brewdays with manual valve changes.

Solution: Added PLC/HMI with lauter rake/flow automation, inline flowmeter to kettle, foam sensor, and CIP conductivity endpoints; standardized water treatment with RO blending.

Results: Brew length reduced by 35–45 minutes; OG variance tightened to ±0.0015; brewhouse efficiency increased from 84% to 89%; caustic use reduced 12% per CIP.

Case Study 2: Water and Energy Optimization at Launch (2024)

Background: A new 10 BBL brewery in a water-restricted area targeted sustainability KPIs.

Solution: Installed heat recovery from wort chilling to HLT, VFD glycol pumps, improved tank/HLT insulation, and CIP reuse where validated.

Results: Water-to-beer improved from 5.3 to 3.7 hL/hL; hot-side energy/BBL down ~15%; annual utility spend reduced ~11% without throughput loss.

Expert Opinions

- Mary Pellettieri, Quality Consultant; Author of “Quality Management for Breweries”

“Lock in fundamentals early—water specs, pH and gravity checks, and validated CIP. These controls outperform ad‑hoc upgrades in driving consistent quality.” - John Mallett, Brewing & Quality Leader; Author of “Malt: A Practical Guide”

“Your beer brewing equipment is only as good as your milling and lauter control. Predictable wort quality starts with a repeatable grist and measured runoff.” - Laura Ulrich, Senior Brewer and Industry Educator

“Smart semi‑automation lets small teams manage fermentation and oxygen control reliably—key for shelf‑stable hop-forward beers.”

Practical Tools/Resources

- Brewers Association: startup checklists, cellar sizing, sustainability benchmarking: https://www.brewersassociation.org

- ASBC Methods (DO, VDK/diacetyl, pH, turbidity): https://www.asbcnet.org

- MBAA Technical Quarterly and webinars (CIP, hygienic design): https://www.mbaa.com

- DOE AMO calculators for process heating, motors/VFDs: https://www.energy.gov/eere/amo/tools

- Bru’n Water for water chemistry planning: https://sites.google.com/site/brunwater

- Brewfather and BeerSmith for recipe and production logging: https://brewfather.app | https://beersmith.com

SEO tip: Internally link the anchor text “beer brewing equipment” to related guides on water treatment, glycol sizing, and CIP validation to improve topical authority and conversions.

Last updated: 2025-09-05

Changelog: Added 5 FAQs, a 2025 trends section with benchmark table and authoritative sources, two recent case studies, expert viewpoints, and practical tools/resources relevant to choosing beer brewing equipment.

Next review date & triggers: 2026-02-01 or earlier if BA/ASBC guidance updates, DOE efficiency factors change, or equipment lead times/pricing shift materially.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?