Commercial Beer Brewing Systems: Key Features and Considerations

Craft beer and microbreweries have become increasingly popular in recent years, leading to a surge in demand for high-quality commercial beer brewing systems. These systems are essential to the beer industry, allowing brewers to produce large quantities of beer efficiently and on a consistent basis. With so many options available, choosing the right commercial beer brewing system can be a daunting task.

In this post, we will provide an overview of the key features and considerations to keep in mind when selecting a commercial beer brewing system. Whether you are a small-scale microbrewery or a large production brewery, this guide will help you make an informed decision and choose a system that meets your specific needs.

Introduction to Commercial Beer Brewing Systems

Beer brewing has a rich history dating back to ancient times. Today, the beer industry is a booming market, with craft beer and microbreweries becoming increasingly popular. Commercial beer brewing systems are essential to this industry, as they allow brewers to produce large quantities of high-quality beer efficiently.

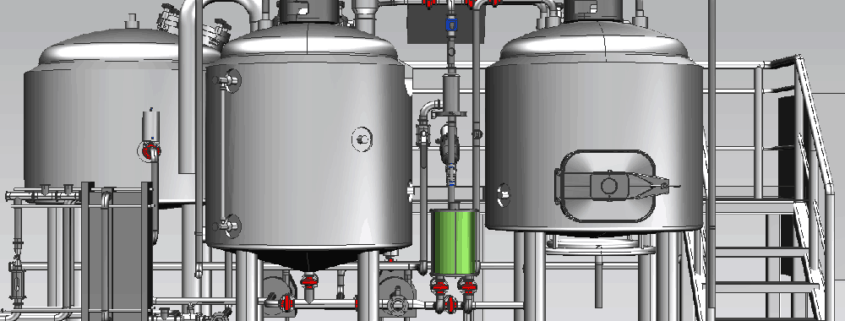

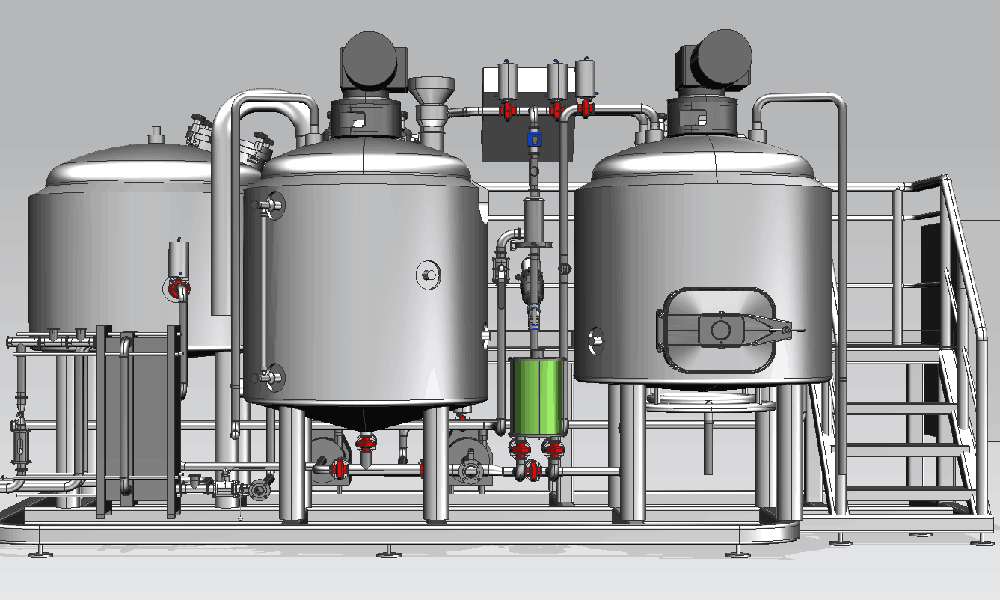

A commercial beer brewing system typically consists of several components, including a mash tun, boil kettle, fermenter, and bottling/canning equipment. These systems can vary in size and complexity, with some being designed for small-scale production, while others are capable of producing thousands of gallons of beer per day.

Key Features of Commercial Beer Brewing Systems

The process of commercial beer brewing involves several key components, each with its own unique function. In this section, we will explore the key features of commercial beer brewing systems, including the mash tun, boil kettle, fermenter, and bottling/canning equipment.

Mash Tun

The mash tun is a critical component of the beer brewing process, where the malted barley is mixed with water and heated to create a sweet liquid called wort. This process, known as mashing, involves breaking down the starches in the barley and converting them into fermentable sugars.

In addition to heating the water and malted barley, the mash tun must also have the ability to mix the ingredients thoroughly. This ensures that the enzymes in the malted barley are distributed evenly and can break down the starches effectively. Furthermore, the mash tun should have a temperature control system to maintain a consistent temperature throughout the mashing process. Moreover, it should be easy to clean to prevent contamination and ensure consistent quality.

Boil Kettle

After the wort has been created in the mash tun, it is transferred to the boil kettle. This is where the wort is boiled with hops to add bitterness and flavor to the beer.

In addition to adding hops, the boil kettle must have the ability to boil the wort effectively to achieve a desired bitterness level. Additionally, it should have a filtration system to remove any impurities from the wort. Consequently, this will improve the clarity and flavor of the beer. Therefore, the boil kettle should be equipped with a heating and cooling system to control the temperature and prevent overheating.

Fermenter

The fermenter is where the wort is transferred after it has been boiled and cooled. Yeast is added to begin the fermentation process, which converts the sugar in the wort into alcohol.

Subsequently, the fermenter must have the ability to maintain a consistent temperature and provide adequate aeration to ensure optimal yeast growth and fermentation. As a result, the fermenter should have a temperature control system and aeration equipment. In conclusion, it should also be designed to prevent contamination and ensure consistent quality.

Bottling/Canning Equipment

Once the beer has finished fermenting, it is transferred to a bottling or canning line, where it is packaged and prepared for distribution.

Furthermore, the bottling/canning equipment should have the ability to fill, seal, and label bottles or cans efficiently and accurately. Additionally, it should be easy to clean and maintain to ensure consistent quality. Moreover, it should have a quality control system to detect any defects or contamination in the finished product.

In conclusion, each component of a commercial beer brewing system plays a critical role in producing high-quality beer. When choosing a system, it is important to consider factors such as capacity, quality control, cost, and ease of use. By selecting the right system for your brewery, you can create delicious beer that meets the high standards of your customers and helps your business thrive.

Considerations When Choosing a Commercial Beer Brewing System

- Capacity: One of the most important considerations when choosing a commercial beer brewing system is the capacity of the system. This will depend on the size of your brewery and the amount of beer you plan to produce.

- Quality Control: Quality control is essential in the beer brewing industry, and a commercial beer brewing system should be designed with this in mind. Look for systems that have built-in quality control features, such as temperature control and monitoring.

- Cost: Commercial beer brewing systems can vary significantly in cost, with some systems costing tens of thousands of dollars. Consider your budget carefully when choosing a system and look for options that offer good value for your money.

- Ease of Use: A commercial beer brewing system can be complex and require specialized knowledge to operate. Look for systems that are user-friendly and offer training and support to help you get started.

Common Types of Commercial Beer Brewing Systems

- Brewpub Systems: Brewpub systems are designed for small-scale production and are often used by microbreweries and brewpubs. These systems typically have a capacity of 3-10 barrels and are designed to be compact and efficient.

- Craft Brewery Systems: Craft brewery systems are designed for larger-scale production and can have a capacity of up to 100 barrels or more. These systems are often custom-built and can be tailored to the specific needs of the brewery.

- Production Brewery Systems: Production brewery systems are designed for the largest-scale production and can have a capacity of several hundred barrels or more. These systems are often fully automated and require a significant investment in equipment and infrastructure.

Conclusion

Commercial beer brewing systems are essential to the beer industry, allowing brewers to produce high-quality beer efficiently and on a large scale. When choosing a commercial beer brewing system, it is essential to consider factors such as capacity, quality control, cost, and ease of use. With the right system in place, brewers can create delicious beer that satisfies their customers and keeps them coming back for more.

Thank you for reading this blog about Commercial Beer Brewing Systems. If you’re looking for a high-quality, durable, and easy-to-use Commercial Beer Brewing Systems, we recommend the brewing equipment brand Yolong Brewtech. Yolong brewing equipment has a good reputation in the market, and their products’ quality and reliability have stood the test of time. To learn more, visit our product page and browse our brewing system products.