Brewhouse Setup: A Comprehensive Guide

Are you planning to set up your own brewery, but you’re not sure where to start? Look no further! In this article, we will walk you through the basics of brewhouse setup, including different configurations, essential equipment, and additional considerations to help you create the perfect brewing space. So grab a pint, sit back, and let’s dive into the world of brewhouse setup!

Types of Brewhouse Configurations

When setting up a brewhouse, one of the first decisions you’ll need to make is the configuration of your brewing system. The three most common configurations are two-vessel, three-vessel, and four-vessel systems.

Two-Vessel System

A two-vessel system combines the functions of a mash tun and lauter tun into one vessel and a boil kettle and whirlpool into another. This setup is ideal for small-scale brewers or those with limited space, as it requires less equipment and a smaller footprint.

Three-Vessel System

In a three-vessel system, the mash tun, lauter tun, and boil kettle are separate vessels, while the whirlpool function is incorporated into the boil kettle. This configuration provides greater control over the brewing process and is suitable for larger-scale operations.

Four-Vessel System

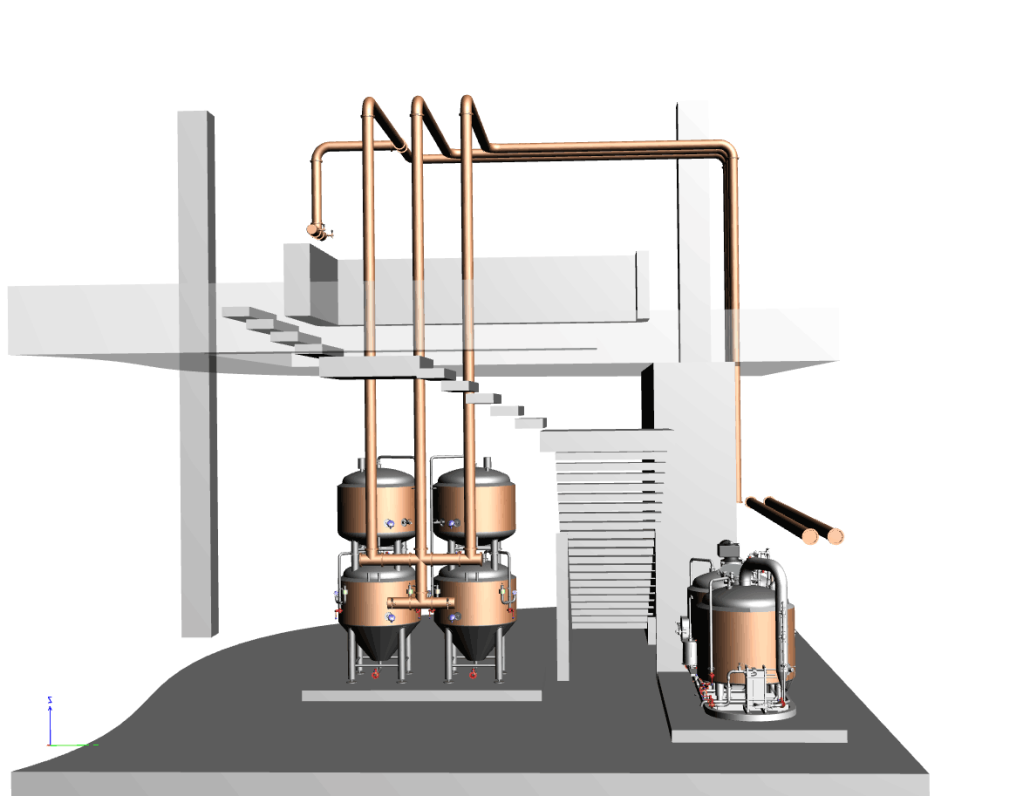

A four-vessel system includes separate vessels for the mash tun, lauter tun, boil kettle, and whirlpool. This configuration allows for maximum efficiency and control over the brewing process, making it ideal for larger breweries or those seeking to optimize their production.

Essential Brewhouse Equipment

Regardless of the configuration you choose, there are four essential pieces of equipment needed for a successful brewhouse setup.

Mash Tun

The mash tun is where the brewing process begins. It’s used to mix crushed grains with hot water, creating a mash that will later be separated into wort and spent grains.

Lauter Tun

The lauter tun is used to separate the wort from the spent grains. This process, called lautering, involves draining the wort through a false bottom while rinsing the grains with hot water to extract as much sugar as possible.

Boil Kettle

In the boil kettle, the wort is heated and boiled

to sterilize it and extract flavors from hops. This stage of the brewing process is crucial for developing the desired taste and aroma of the finished beer.

Whirlpool

The whirlpool is used after boiling to separate hop particles, proteins, and other solid matter from the wort. By creating a vortex in the liquid, the solids are forced to the center of the vessel, making it easier to transfer the clear wort to the fermentation tanks.

Additional Brewing Equipment

In addition to the essential brewhouse equipment, there are several other pieces of equipment that can enhance your brewing process.

Heat Exchanger

A heat exchanger is used to cool the wort quickly after boiling, which is essential for preventing off-flavors and promoting proper yeast activity during fermentation.

Fermentation Tanks

Fermentation tanks, also known as fermenters or unitanks, are where the cooled wort is mixed with yeast to initiate fermentation. These tanks come in various sizes and materials, with stainless steel being the most common.

Pumps and Piping

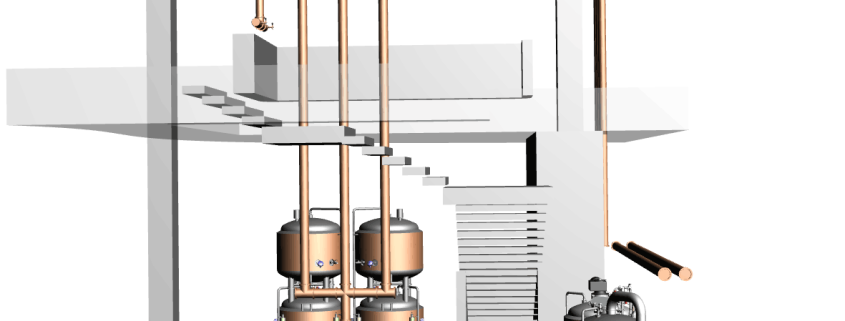

Efficient pumps and piping are crucial for transferring liquid between vessels during the brewing process. Investing in high-quality pumps and well-designed piping systems will ensure smooth operations and reduce the risk of contamination.

Brewhouse Automation and Control Systems

Automation and control systems can significantly improve the consistency and efficiency of your brewing process. These systems can range from simple temperature and flow control devices to more advanced systems that fully automate the entire brewing process. Choosing the right level of automation will depend on your budget, production goals, and brewing experience.

Choosing the Right Brewhouse Size

The size of your brewhouse will depend on factors such as your production goals, available space, and budget. Start by determining your expected brewing capacity, measured in barrels (BBL), and consider future growth when making your decision. It’s generally better to invest in a slightly larger system to accommodate future expansion rather than outgrowing your brewhouse too quickly.

Brewhouse Setup Costs

Setting up a brewhouse can require a significant financial investment, which varies depending on factors such as the size of the operation, equipment quality, and automation level. To give you a general idea, brewhouse setup costs can range from $100,000 to $1 million. Nevertheless, remember that there are ongoing expenses to consider, such as maintenance, raw materials, and labor.

Firstly, the size of your brewing operation plays a crucial role in determining the overall cost. Generally, larger systems demand a higher investment, but they can also increase your production capacity. Therefore, it’s essential to find a balance between your budget and production goals.

Secondly, the quality of the equipment is a vital factor to consider. Although investing in high-quality equipment might seem expensive upfront, it usually leads to more reliable and consistent brewing results. Moreover, it can save you money on maintenance and replacements in the long run.

Next, the level of automation you choose can significantly impact the cost of your brewhouse setup. While basic control systems are more affordable, advanced automation systems can be pricey. However, these systems can improve efficiency, consistency, and ease of operation, which may offset the initial investment over time.

Lastly, don’t forget about ongoing costs, as they are a critical aspect of your brewhouse budget. Regular maintenance, purchasing raw materials, and employing skilled labor are all expenses that you need to factor in when planning your brewhouse setup.

In conclusion, thoroughly assessing your requirements, researching different equipment options, and consulting with industry professionals can help you make informed decisions regarding the costs associated with your brewhouse setup.

Tips for a Successful Brewhouse Setup

- Plan your space carefully, taking into account workflow, storage, and future expansion.

- Invest in high-quality equipment to ensure reliable and consistent brewing results.

- Consult with experienced brewers and industry professionals to gain valuable insights and advice.

- Prioritize safety and sanitation to protect your product and employees.

- Be prepared for unexpected challenges and be willing to adapt as you learn and grow.

Conclusion

Setting up a brewhouse can be a complex and challenging endeavor, but with careful planning and attention to detail, you can create a successful brewing operation. By understanding the different brewhouse configurations, investing in essential equipment, and considering factors like automation and size, you’ll be well on your way to brewing your first batch of delicious beer!

Thank you for reading this blog about Brewhouse Setup. If you’re looking for a high-quality, durable, and easy-to-use Brewhouse for Sale, we recommend the brewing equipment brand Yolong Brewtech. Yolong brewing equipment has a good reputation in the market, and their products’ quality and reliability have stood the test of time. To learn more, visit our product page and browse our brewing system products.