7 Barrel Brewing System: Everything You Need to Know

If you’re planning to start a microbrewery, then you need to know about the equipment that goes into it. One of the most critical pieces of equipment is the brewing system. While there are different types and sizes of brewing systems, the 7 barrel brewing system is one of the most popular choices. In this article, we’ll cover everything you need to know about the 7 barrel brewing system.

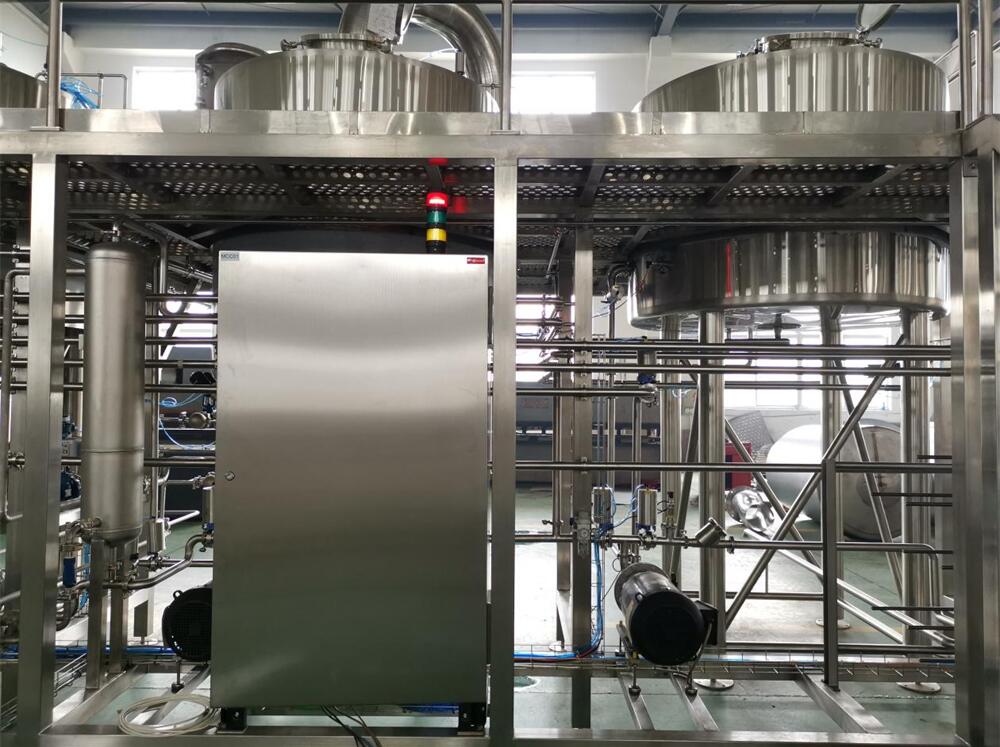

What is a 7 barrel brewing system?

A 7 barrel brewing system is a type of brewing equipment used for producing beer. The term “barrel” in the brewing industry refers to a volume measurement equivalent to 31 US gallons or 26 imperial gallons. Therefore, a 7 barrel brewing system can produce 217 US gallons or 181 imperial gallons of beer in one batch.

How does a 7 barrel brewing system work?

A 7 barrel brewing system works by following a series of steps. Firstly, the grains are milled and added to the mash tun. Water is added to the mash tun, and the mixture is heated to a specific temperature to activate the enzymes in the grains that convert the starches to sugar. The resulting liquid, called wort, is transferred to the boil kettle, where it is boiled with hops to add flavor and bitterness to the beer. After boiling, the wort is cooled in the wort chiller and transferred to the fermenters, where yeast is added to ferment the sugar into alcohol.

Benefits of a 7 barrel brewing system

There are many benefits of a 7 barrel brewing system, which makes it a popular choice for many microbreweries. Here are some of the benefits:

Economical

Compared to larger brewing systems, a 7 barrel brewing system is more economical as it requires less space, water, and power. It also has a lower initial investment cost and is easier to operate and maintain.

Efficient

A 7 barrel brewing system is designed to be efficient, with a high level of automation, which makes it easier to use and reduces the risk of errors. It also has a shorter brewing time, which means you can produce more beer in less time.

Versatile

A 7 barrel brewing system can produce a wide range of beer styles, from light lagers to heavy stouts. It also allows for experimentation with different ingredients and brewing techniques.

Scalable

A 7 barrel brewing system is scalable, which means you can increase your production capacity by adding more fermenters or upgrading to a larger brewing system.

Consistent

A 7 barrel brewing system is designed to produce consistent beer batches, which means you can maintain the quality and flavor of your beer from batch to batch. This is important for building a loyal customer base and maintaining your brand reputation.

Features of a 7 barrel brewing system

A 7 barrel brewing system is composed of several key components. Here are some of the features you can expect from a typical 7 barrel brewing system:

Mash Tun

The mash tun is where the grains are mixed with water to activate the enzymes that convert the starches to sugar. The mash tun is insulated to maintain a constant temperature and can be heated using direct fire, electric, or steam.

Boil Kettle

The boil kettle is where the wort is boiled with hops to add flavor and bitterness to the beer. The boil kettle is also insulated and can be heated using direct fire, electric, or steam.

Hot Liquor Tank

The hot liquor tank is used to store hot water that is used in the brewing process. It can also be used to preheat the water before it is added to the mash tun.

Wort Chiller

The wort chiller is used to cool the boiled wort before it is transferred to the fermenters. It can be cooled using either water or glycol.

Fermenters

The fermenters are where the yeast is added to ferment the sugar into alcohol. Fermenters come in various sizes and can be made from stainless steel, plastic, or wood.

Factors to consider when choosing a 7 barrel brewing system

When choosing a 7 barrel brewing system, there are several factors to consider:

Space

A 7 barrel brewing system requires a significant amount of space, both for the brewing equipment and for storing the finished beer. Ensure that you have enough space before investing in a 7 barrel brewing system.

Budget

A 7 barrel brewing system can be a significant investment, so it’s essential to have a budget in mind before making a purchase.

Production needs

Consider your production needs before choosing a 7 barrel brewing system. If you plan to expand your business in the future, you may want to choose a system that is scalable.

Power requirements

Different types of 7 barrel brewing systems have different power requirements. Ensure that your facility can accommodate the power needs of your chosen system.

Maintenance and care of a 7 barrel brewing system

Maintaining and caring for your 7 barrel brewing system is crucial to ensure that it operates efficiently and produces high-quality beer. Here are some tips for proper maintenance and care:

Regular Cleaning

Regular cleaning is essential to remove any dirt, debris, or bacteria that may be present in the brewing system. Ensure that you clean all parts of the system thoroughly, including the mash tun, boil kettle, hot liquor tank, wort chiller, and fermenters. Use a cleaning solution that is specifically designed for brewing equipment and follow the manufacturer’s instructions.

Sanitization

Sanitization is critical to prevent contamination and ensure that your beer is safe to drink. Use a sanitizer that is appropriate for brewing equipment, and ensure that you follow the manufacturer’s instructions. Sanitize all parts of the system, including hoses, valves, and fittings.

Maintenance

Regular maintenance is necessary to ensure that your brewing system operates efficiently and produces high-quality beer. Check all parts of the system regularly for signs of wear and tear and replace any damaged parts immediately. Lubricate any moving parts as needed and tighten any loose bolts or fittings.

Spare Parts and Supplies

Ensure that you have spare parts and supplies on hand in case of equipment failure. This includes replacement hoses, valves, and fittings, as well as cleaning and sanitizing solutions. Keeping spare parts on hand will help you avoid any downtime in production and keep your brewing system operating efficiently.

In conclusion, regular cleaning, sanitization, maintenance, and having spare parts and supplies on hand are essential to maintaining and caring for your 7 barrel brewing system. By following these tips, you can ensure that your brewing system operates efficiently and produces high-quality beer consistently.

Conclusion

A 7 barrel brewing system is an excellent choice for a microbrewery. It’s economical, efficient, versatile, scalable, and produces consistent beer batches. When choosing a 7 barrel brewing system, consider factors such as space, budget, production needs, and power requirements. Finally, remember to maintain and care for your equipment to ensure that it operates efficiently and produces high-quality beer.

Thank you for reading this blog about 7 barrel brewing system. If you’re looking for a high-quality, durable, and easy-to-use 7 barrel brewing system, we recommend the brewing equipment brand Yolong Brewtech. Yolong brewing equipment has a good reputation in the market, and their products’ quality and reliability have stood the test of time. To learn more, visit our product page and browse our brewing system products.