Commercial Beer Brewing Systems: Key Features and Considerations

Craft beer and microbreweries have become increasingly popular in recent years, leading to a surge in demand for high-quality commercial beer brewing systems. These systems are essential to the beer industry, allowing brewers to produce large quantities of beer efficiently and on a consistent basis. With so many options available, choosing the right commercial beer brewing system can be a daunting task.

In this post, we will provide an overview of the key features and considerations to keep in mind when selecting a commercial beer brewing system. Whether you are a small-scale microbrewery or a large production brewery, this guide will help you make an informed decision and choose a system that meets your specific needs.

Introduction to Commercial Beer Brewing Systems

Beer brewing has a rich history dating back to ancient times. Today, the beer industry is a booming market, with craft beer and microbreweries becoming increasingly popular. Commercial beer brewing systems are essential to this industry, as they allow brewers to produce large quantities of high-quality beer efficiently.

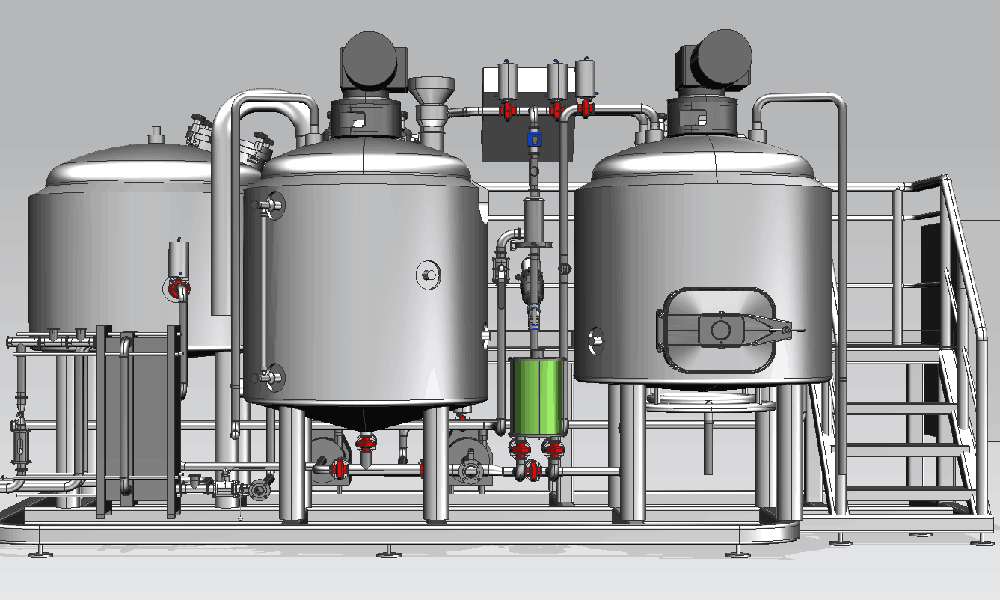

A commercial beer brewing system typically consists of several components, including a mash tun, boil kettle, fermenter, and bottling/canning equipment. These systems can vary in size and complexity, with some being designed for small-scale production, while others are capable of producing thousands of gallons of beer per day.

Key Features of Commercial Beer Brewing Systems

The process of commercial beer brewing involves several key components, each with its own unique function. In this section, we will explore the key features of commercial beer brewing systems, including the mash tun, boil kettle, fermenter, and bottling/canning equipment.

Mash Tun

The mash tun is a critical component of the beer brewing process, where the malted barley is mixed with water and heated to create a sweet liquid called wort. This process, known as mashing, involves breaking down the starches in the barley and converting them into fermentable sugars.

In addition to heating the water and malted barley, the mash tun must also have the ability to mix the ingredients thoroughly. This ensures that the enzymes in the malted barley are distributed evenly and can break down the starches effectively. Furthermore, the mash tun should have a temperature control system to maintain a consistent temperature throughout the mashing process. Moreover, it should be easy to clean to prevent contamination and ensure consistent quality.

Boil Kettle

After the wort has been created in the mash tun, it is transferred to the boil kettle. This is where the wort is boiled with hops to add bitterness and flavor to the beer.

In addition to adding hops, the boil kettle must have the ability to boil the wort effectively to achieve a desired bitterness level. Additionally, it should have a filtration system to remove any impurities from the wort. Consequently, this will improve the clarity and flavor of the beer. Therefore, the boil kettle should be equipped with a heating and cooling system to control the temperature and prevent overheating.

Fermenter

The fermenter is where the wort is transferred after it has been boiled and cooled. Yeast is added to begin the fermentation process, which converts the sugar in the wort into alcohol.

Subsequently, the fermenter must have the ability to maintain a consistent temperature and provide adequate aeration to ensure optimal yeast growth and fermentation. As a result, the fermenter should have a temperature control system and aeration equipment. In conclusion, it should also be designed to prevent contamination and ensure consistent quality.

Bottling/Canning Equipment

Once the beer has finished fermenting, it is transferred to a bottling or canning line, where it is packaged and prepared for distribution.

Furthermore, the bottling/canning equipment should have the ability to fill, seal, and label bottles or cans efficiently and accurately. Additionally, it should be easy to clean and maintain to ensure consistent quality. Moreover, it should have a quality control system to detect any defects or contamination in the finished product.

In conclusion, each component of a commercial beer brewing system plays a critical role in producing high-quality beer. When choosing a system, it is important to consider factors such as capacity, quality control, cost, and ease of use. By selecting the right system for your brewery, you can create delicious beer that meets the high standards of your customers and helps your business thrive.

Considerations When Choosing a Commercial Beer Brewing System

- Capacity: One of the most important considerations when choosing a commercial beer brewing system is the capacity of the system. This will depend on the size of your brewery and the amount of beer you plan to produce.

- Quality Control: Quality control is essential in the beer brewing industry, and a commercial beer brewing system should be designed with this in mind. Look for systems that have built-in quality control features, such as temperature control and monitoring.

- Cost: Commercial beer brewing systems can vary significantly in cost, with some systems costing tens of thousands of dollars. Consider your budget carefully when choosing a system and look for options that offer good value for your money.

- Ease of Use: A commercial beer brewing system can be complex and require specialized knowledge to operate. Look for systems that are user-friendly and offer training and support to help you get started.

Common Types of Commercial Beer Brewing Systems

- Brewpub Systems: Brewpub systems are designed for small-scale production and are often used by microbreweries and brewpubs. These systems typically have a capacity of 3-10 barrels and are designed to be compact and efficient.

- Craft Brewery Systems: Craft brewery systems are designed for larger-scale production and can have a capacity of up to 100 barrels or more. These systems are often custom-built and can be tailored to the specific needs of the brewery.

- Production Brewery Systems: Production brewery systems are designed for the largest-scale production and can have a capacity of several hundred barrels or more. These systems are often fully automated and require a significant investment in equipment and infrastructure.

Conclusion

Commercial beer brewing systems are essential to the beer industry, allowing brewers to produce high-quality beer efficiently and on a large scale. When choosing a commercial beer brewing system, it is essential to consider factors such as capacity, quality control, cost, and ease of use. With the right system in place, brewers can create delicious beer that satisfies their customers and keeps them coming back for more.

Thank you for reading this blog about Commercial Beer Brewing Systems. If you’re looking for a high-quality, durable, and easy-to-use Commercial Beer Brewing Systems, we recommend the brewing equipment brand Yolong Brewtech. Yolong brewing equipment has a good reputation in the market, and their products’ quality and reliability have stood the test of time. To learn more, visit our product page and browse our brewing system products.

- automated brewing system

- professional beer brewing

- brewhouse setup

- micro brewery startup

- brewery design

- 7 Barrel Brewing System

Additional FAQs about Commercial Beer Brewing Systems

- Q: What brewhouse size fits a new microbrewery with a taproom?

A: Common start points are 7–15 bbl brewhouses with 2–4× cellar capacity in fermenters (e.g., four 15–30 bbl FVs). Size to expected weekly turns, available utilities, and future expansion. - Q: Should I choose steam, electric, or direct-fire heating?

A: Steam offers the best control and scalability; electric is cleaner and often easier to permit but limited by power availability; direct-fire can be cost-effective with good venting. Model total cost of ownership (TCO) across utilities, maintenance, and control precision. - Q: What level of automation is worth it at production scale?

A: For 15 bbl+ systems, semi-automation (recipe steps, temperature/PID, flow/pump interlocks) typically pays back via repeatability and labor savings. Full PLC/SCADA adds CIP automation, alarms, and traceability for larger plants. - Q: How do I plan cellaring for mixed fermentation and lagers?

A: Combine pressure-rated unitanks for ales/lagers with at least one horizontal lagering or BBT for faster clarification. Include spunding, DO monitoring, and cold-side O2 control for shelf stability. - Q: What certifications and compliance should the system meet?

A: Look for ASME/PED for pressure vessels, UL/CE for electrical panels, local gas/steam code compliance, and food-contact documentation (materials traceability and weld/passivation records).

2025 Industry Trends for Commercial Beer Brewing Systems

- Energy and water efficiency: heat recovery on wort cooling, insulated vessels, and optimized CIP cut utilities by 10–25%.

- Data and traceability: affordable PLC/SCADA with batch records, alarm histories, and digital QA logs become standard from 10 bbl upward.

- Oxygen control: closed transfers, CO2-purged dry-hopping, and routine DO checks (<50–100 ppb in package) are widespread.

- Flexible cellars: pressure-capable unitanks with multi-zone jackets and faster crash capability support diverse styles and quicker turns.

- Electrification and permitting: more electric brewhouses where gas constraints exist; hybrid steam/electric solutions to manage peak loads.

2025 Benchmarks and Cost Ranges for Commercial Systems

| Category | Typical Range (craft scale) | Notes |

|---|---|---|

| Brewhouse size | 7–60 bbl | Brewpubs often 7–15 bbl; regional 30–60 bbl |

| Brewhouse efficiency | 72–86% | Geometry, crush, lauter setup impact |

| Boil-off rate | 6–10%/h | Venting and heat source dependent |

| Water-to-beer ratio | 3.2–5.0:1 | With HX heat recovery and optimized CIP |

| Knockout DO | <0.10–0.30 ppm | Closed knockout preferred |

| Package DO | <50–100 ppb | Shelf life and hop stability driver |

| Energy per bbl (kettle heat) | 12–25 kWh electric or NG equivalent | Ambient and groundwater temperature matter |

| Turnkey brewhouse cost (7–15 bbl) | $150k–$600k | Controls, automation, and finish drive variance |

| Full plant CAPEX (15–30 bbl w/ cellar + utilities) | $750k–$2.5M+ | Facility work, glycol, steam/electric, packaging |

Sources: Brewers Association Sustainability Benchmarking Tools; MBAA Technical Quarterly; manufacturer datasheets (2024–2025). Validate with local utilities and code authorities.

Latest Research Cases

Case Study 1: Closed Cold-Side and Spunding Enhance Shelf Stability (2025)

- Background: A 20 bbl production brewery experienced hop fade and papery notes by day 60 in distribution.

- Solution: Implemented CO2-purged hoses and vessels, spunded at 0.8–1.0 bar near terminal gravity, added inline DO spot checks pre‑package, and standardized BBT purging.

- Results: Median package DO fell from 135 ppb to 62 ppb; staling descriptors in sensory dropped 50%; average tank time decreased by 1.5 days.

Case Study 2: Utility Optimization Cuts Operating Costs (2024)

- Background: Rising energy/water costs strained margins on a 15 bbl brewhouse.

- Solution: Added wort-heat recovery to preheat brew liquor, increased insulation on kettles/piping, installed VFDs on pumps, and validated CIP with conductivity endpoints.

- Results: Energy per bbl decreased 17%; water-to-beer ratio improved from 5.1:1 to 4.0:1; annual savings estimated at $28,000 with <12‑month payback.

Sources: Brewers Association Quality and Sustainability toolkits; MBAA TQ case notes; supplier application guides on oxygen control, heat recovery, and CIP validation. Results vary by site and SOP discipline.

Expert Opinions

- Mary Pellettieri, Brewing Quality Consultant; Author of “Quality Management for Breweries”

- Viewpoint: “Invest first in oxygen control and validated cleaning—those two pillars protect flavor and extend shelf life.”

- Reference: Brewers Association Quality Resources (https://www.brewersassociation.org/)

- John Mallett, Former VP Operations, Bell’s Brewery; Author of “Malt”

- Viewpoint: “Specify weld quality, surface finish, jacket zoning, and accurate instrumentation before chasing advanced automation.”

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

- Viewpoint: “Match thermal histories from brewhouse to fermentation to achieve consistent hop expression at production scale.”

Practical Tools and Resources

- Brewers Association: Quality, Safety, Sustainability, and Benchmarking Tools — https://www.brewersassociation.org/

- Master Brewers Association of the Americas (MBAA) Technical Quarterly — https://www.mbaa.com/

- ASME BPVC and EU PED (pressure vessel compliance) — https://www.asme.org/ and https://single-market-economy.ec.europa.eu/

- Process software for planning and QA: OrchestratedBEER/NetSuite, Ekos, Brewfather (https://brewfather.app/), BeerSmith (https://beersmith.com/)

- DO/CO2 and QA instrumentation: Anton Paar (https://www.anton-paar.com/), Haffmans/Pentair (https://foodandbeverage.pentair.com/), Zahm & Nagel (https://zahmnagel.com/)

- Equipment marketplaces and vendor directories: ProBrewer Classifieds (https://www.probrewer.com/), Brewers Association Supplier Directory

Last updated: 2025-09-04

Changelog: Added five targeted FAQs; inserted 2025 benchmarks table for performance and costs; provided two recent case studies on cold-side oxygen control and utility optimization; included expert viewpoints; curated practical tools/resources with authoritative links.

Next review date & triggers: 2026-03-01 or earlier if BA/MBAA publish updated benchmarks, new oxygen/cold-side standards emerge, or major changes in utility costs/permits affect brewhouse technology choices.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?