The Best Price Automated Medium Brewing Systems of 2022

/Last Update May 19,2022 /By YoLong Brewtech

With the continuous application of Industry 4.0, today we are talking about the best priced automated small and medium brewing systems.

Of course, whether you are a senior brewing master or a new brewing apprentice, today we will provide you with part of the application of automation technology in brewing equipment. YoLong Brewtech is willing to share with anyone who likes to brew and become your most loyal brewing equipment partner.

Small breweries face unique challenges that larger breweries do not. They have limited resources, including space, equipment, and staff. They must also be able to produce high-quality beer consistently in order to maintain their reputation and compete with larger breweries. Automation technology can help small breweries overcome these challenges by streamlining processes, increasing efficiency, and reducing the risk of human error.

How is Automation in Small Breweries Different from Large Breweries?

Large breweries typically have a high degree of automation, with complex systems that control everything from the temperature of the mash to the filling and packaging of the beer. Small breweries, on the other hand, can benefit from automation technology without requiring the same level of investment. They can focus on automating the processes that will have the biggest impact on their efficiency and quality, without automating everything.

Benefits of Automation for Small Breweries

There are many benefits to automating processes in small breweries. Here are just a few:

- Increased Efficiency: Automating processes can significantly reduce the amount of time and effort required to produce beer. For example, an automated brewing system can control the temperature and timing of the mash, freeing up staff to focus on other tasks.

- Consistent Quality: Automation can help ensure that beer is brewed to the same high quality every time. By controlling variables such as temperature, pH, and yeast pitching rates, the brewer can ensure that each batch of beer tastes the same.

- Reduced Risk of Human Error: Even the most experienced brewers can make mistakes. Automation technology can help reduce the risk of human error by controlling the brewing process and ensuring that each step is completed correctly.

- Cost Savings: By reducing the time and effort required to produce beer, automation technology can help small breweries save money on labor costs. It can also help reduce waste by ensuring that each batch of beer is brewed correctly.

YoLong: A Budget-Friendly Brewing System for Small Breweries

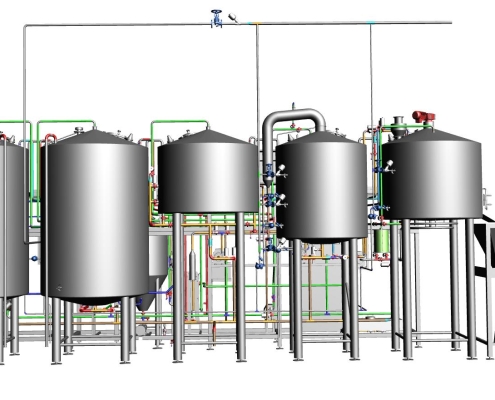

YoLong is a brewing system that is specifically designed for small breweries on a budget. It is a compact and fully automated system that can produce up to 5,000 liters of beer per batch. YoLong’s brewing system is modular, which means that it can be expanded over time as the brewery grows.

In conclusion, Automation technology is revolutionizing the brewing industry, and small breweries can benefit just as much as large breweries. By automating processes, small breweries can increase efficiency, produce high-quality beer consistently, reduce the risk of human error, and save money on labor costs.

Start Today

Estimating the cost of brewery equipment

The YoLong difference

High quality customized brewing system solution provider

Since 2004, YoLong Brewtech has communicated with thousands of breweries around the world, learned from each other, summarized and designed control modes and methods suitable for micro breweries. We are proud to be able to design and optimize customized brewing systems for micro breweries. Provide customized solutions.

what do you need to know about custom brewery systems as a brewer?

As a professional equipment manufacturer, YL technical team can provide a complete service from design to installation according to your site.

1:Customized design of brewery and cellar tank layout and specific specifications

When it comes to designing a custom brewery system, the layout of the brewery and cellar tanks is critical. The layout must be designed to suit the space available and the brewer’s unique brewing process. Customized specifications are also required to ensure that the system meets the specific needs and requirements of the brewer.

The design of the brewery and cellar tank layout is an essential aspect of a custom brewery system. The layout must be optimized to allow for maximum efficiency and output. This involves selecting the right size and number of tanks, as well as designing a layout that allows for the easy movement of materials and equipment. The layout should also be designed to prevent cross-contamination, ensuring that each beer produced is of high quality and consistent.

In addition to the layout of the brewery and cellar tanks, the specifications of the system must also be customized. This includes the size and capacity of the system, as well as the materials used to construct it. The specific needs of the brewer must be considered when selecting materials, such as stainless steel, to ensure that the system is durable and easy to maintain.

Customized specifications also include the selection of the right equipment and technology for the brewing process. This includes selecting the right brewhouse, mash tun, and fermenters, as well as the equipment required for cleaning and sanitizing the system. Customized specifications also include the selection of the right pumps, valves, and hoses, as well as the right heating and cooling systems to maintain the proper temperature throughout the brewing process.

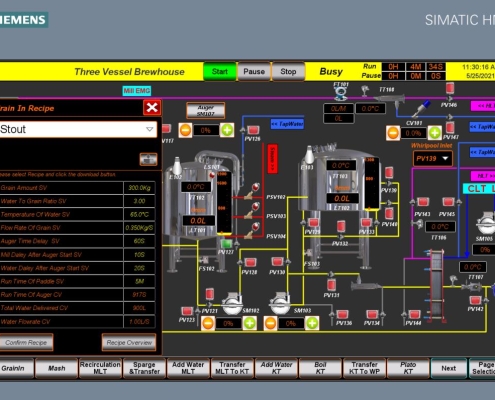

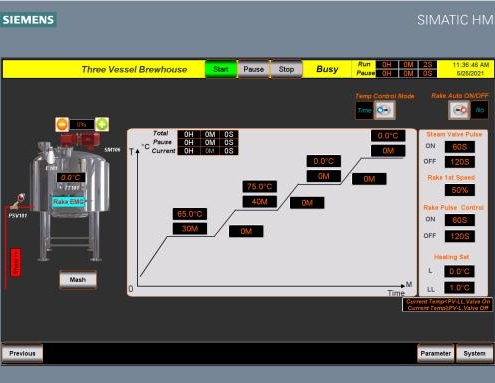

2:First-class control system, from optional automatic control options to fully automatic control

Custom brewery systems are equipped with a first-class control system that provides brewers with the flexibility to choose between optional automatic control options or fully automatic control. The control system allows the brewer to control the entire brewing process, from mashing to fermentation, with ease.

The control system is designed to provide precise control over the brewing process, ensuring that each step is carried out correctly. The control system is also designed to be user-friendly, allowing brewers to easily program the system to follow a specific brewing recipe or adjust the process as needed.

Optional automatic control options include semi-automatic control, which allows the brewer to control some aspects of the process manually while the system controls others automatically. For example, the brewer may manually add the ingredients to the mash tun, while the system controls the temperature and the flow of the liquid.

Fully automatic control, on the other hand, allows the brewer to program the entire brewing process, from mashing to fermentation, and the system controls all aspects of the process. This includes the temperature, the flow of liquid, and the timing of each step of the process.

The control system is also designed to provide real-time monitoring of the brewing process. This allows the brewer to monitor the progress of the process and make adjustments as needed. For example, if the temperature of the mash tun is too high or too low, the brewer can adjust the temperature using the control system.

ARE YOU HAVE BREWING QUESTIONS?

3:Visualization of brewing recipes and automatic brewing procedures

Custom brewery systems are designed to make the brewing process easy and efficient. One of the features of custom brewery systems is the visualization of brewing recipes and automatic brewing procedures. This means that the system can be programmed to follow a specific brewing recipe automatically. The brewer can also monitor the progress of the brewing process in real-time, ensuring that every step of the process is done correctly.

To start the brewing process, the brewer first confirms the brewing formula parameters. Once the parameters are confirmed, the brewer clicks the parameter confirmation button and selects “Yes” in the pop-up window to start the “Grain In” process.

The Grain In process controls the feeding process, and the system will automatically adjust the water temperature, water speed, and other parameters to better mix the material and water. This ensures that the ingredients are properly mixed, resulting in a high-quality beer.

The brewing recipe and automatic brewing procedures are visualized on the control system’s user interface, allowing the brewer to monitor the progress of the brewing process in real-time. The system provides alerts if any step of the process is not carried out correctly, allowing the brewer to make adjustments as needed.

Automatic brewing procedures also include the transfer of the wort from the mash tun to the kettle, the addition of hops, and the cooling of the wort before it is transferred to the fermenter. These steps are all carried out automatically by the system, ensuring that the brewing process is consistent and precise.

4:The application of PLC (Programmable Logic Controller) and HMI (Human Machine Interface) in the brewing process and cellar control

Custom brewery systems are equipped with advanced technology such as Programmable Logic Controller (PLC) and Human Machine Interface (HMI) to control the brewing process and cellar control.

PLC is an industrial computer used to control the process and monitor the system in custom brewery systems. It is used to automate the brewing process, controlling the timing and sequence of each step of the process. The PLC is programmed to follow a specific brewing recipe, ensuring that each batch of beer is consistent and of high quality.

The HMI is a user-friendly interface that allows the brewer to easily control the system. It provides real-time monitoring of the brewing process, allowing the brewer to monitor the temperature, flow rate, and other important parameters. The HMI also provides alerts if any step of the process is not carried out correctly, allowing the brewer to make adjustments as needed.

One of the advanced brewing techniques that can be achieved with the use of PLC and HMI is segmented leaching brewing. Segmented leaching brewing is a brewing technique that involves leaching the grains in several batches rather than all at once. This results in better control over the extraction of sugars from the grains, resulting in a more consistent and flavorful beer.

PLC and HMI also provide precise control over the cellar control system. This includes the temperature control of the fermenters and other equipment used in the brewing process. The system can be programmed to maintain a specific temperature range, ensuring that the beer ferments correctly.

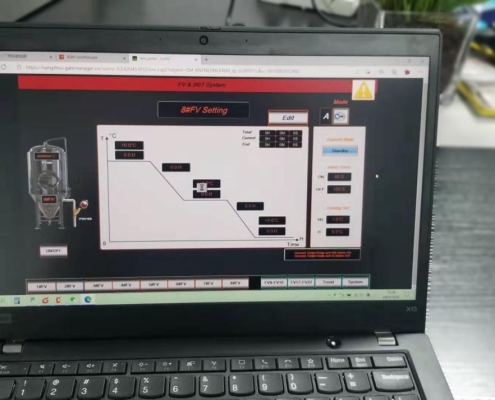

5:Off-site monitoring and remote access

Off-site monitoring and remote access are essential features of custom brewery systems that allow brewers to monitor and control the brewing process from a remote location. This is particularly useful for brewers who have multiple locations or who need to monitor the brewing process while away from the brewery.

Custom brewery systems can be accessed remotely through a secure internet connection. This allows the brewer to monitor the progress of the brewing process, including temperature, pressure, and flow rate, from any location. The system can also send alerts to the brewer if any aspect of the brewing process is not carried out correctly, allowing for timely adjustments to be made.

Remote access also allows the brewer to control the brewing process, adjusting the temperature or flow rate, for example, as needed. This means that the brewer can make changes to the brewing process in real-time, even when they are not physically present at the brewery.

Off-site monitoring and remote access also provide a level of security for the brewery. The system can be set up to send alerts if there is any unauthorized access to the system or if any equipment fails. This ensures that the brewing process is not compromised, and any issues can be addressed immediately.

BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to nano brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- 1:Help expand your recipes.

2:Learn how the Nano brewing system works

3:Convince potential clients that you are on the right track.

4:Be your most reliable “brewery problem solver” partner

5:Make your commercial brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!