Size Matters: How much headspace do you need in a fermenter?

What is “Head Space”? How is it defined? What is its use?

I think these questions will come to mind when you see that concept for the first time.

The concept of “headspace” usually appears in the description of the tank and is read by the customer as a parameter.

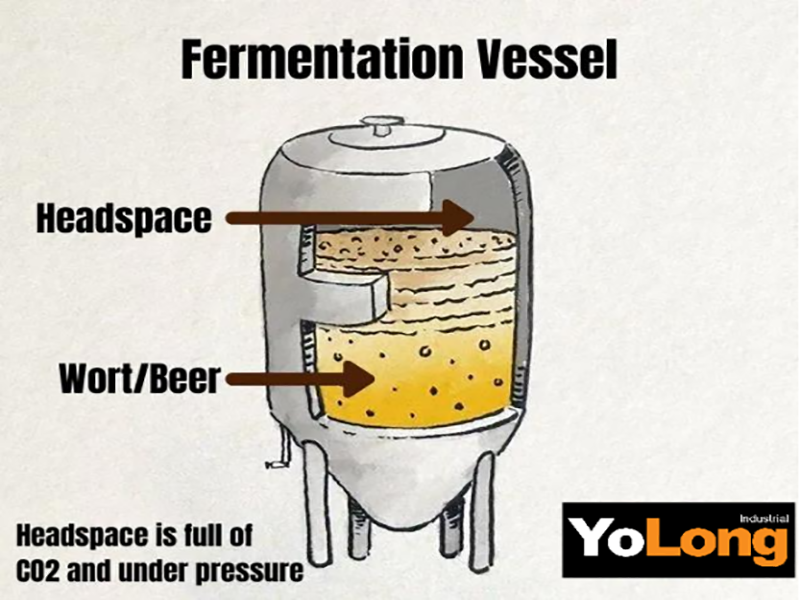

- What is “headspace”?

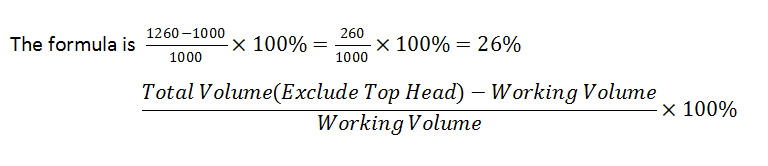

That is a concept used to describe the empty space in the fermentation tanks. That space should not be full of any material. It’s the safe margin of the tank. The pressure tanks must have enough head space to ensure security. - How is it defined?①Regular HeadspaceFor Example: 10HL Fermentation Vessel (Regular Headspace:25% exclude top head)

Working Volume: 1000L

Total Volume (Exclude Top Head): 1260L

Grand Total Volume (Include Top Head): 1416L

Head Space (Exclude Top Head): 26%

This is Yo Long’s standard of headspace for fermentation vessels.

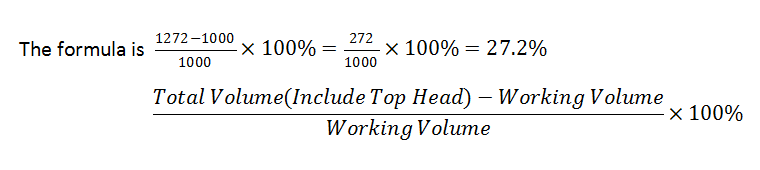

②Small Headspace

Also, there is another formula to calculate headspace:

10HL Fermentation Vessel (Small Head Space:25% include top head)

Working Volume: 1000L

Total Volume (Exclude Top Head): 1136L

Grand Total Volume (Include Top Head): 1272L

Headspace (Include Top Head): 27%

The only difference between these two formulas is the total volume, which includes the top head.

Choosing the appropriate headspace fermentation vessel depends on what the brewer thinks about the beer he would like to create.

- What’s its use?

The head space is used to:

Digitally define the empty space in the tank.

Maintain normal use of the spray ball.

Maintain the normal pressure safety factor of the tank.

There will be a spray ball at the top of the tank for CIP cleaning which should not be submerged in liquid. The position of the CIP spray ball is slightly higher than the sidewall. So the liquid level should not be beyond the sidewall, not to mention reaching the top dished head.

You need enough space to allow gases to safely escape the fermenter without leading to an explosion while simultaneously giving the foam produced enough space to expand before sinking back into the beer.

There are other gases that are produced during the fermentation process, but CO2 is by far the most abundant. In the early growth stage, within the first couple of days of fermentation, CO2 will rise out of your beer and combine with other compounds in the beer to form a foamy layer.

When the foamy layer sinks back into the beer later in fermentation, it gives us back some of those compounds which form it. These compounds, proteins for example, will help contribute to things like the head retention of your beer.

Frequently Asked Questions (FAQ)

1) How much headspace do I need for different beer styles?

- Ales 15–25%; high-gravity or heavily dry-hopped beers 20–30%; lagers under pressure 12–20% if blow-off capacity is ample; wheat/Belgian strains tend to need 20–30% due to high krausen.

2) Does pressure fermentation change required headspace?

- Yes. With spunding (8–15 psi) foam height may reduce slightly, but gas accumulation risk increases. Keep conservative headspace or ensure oversized PRV and blow-off piping.

3) Should headspace be calculated including the top dished head?

- For safety and CIP coverage, base “usable headspace” on straight-side volume. Many vendors quote headspace including the top head; validate both figures to avoid submerging the spray ball.

4) How do dry-hop charges affect headspace needs?

- Pellets nucleate CO2 and can trigger “hop volcanoes.” Plan 5–10% extra headspace on big charges or use a purged hop doser/torpedo and dose post-peak fermentation.

5) What’s the impact of under-sizing headspace?

- Risks include blow-off loss, clogged PRVs, contaminated ceilings, inconsistent gravities, and DO pickup from emergency interventions. It can also compromise CIP if spray devices get submerged.

2025 Industry Trends: Headspace Planning in Modern Fermentation

- Pressure-capable unitanks with spunding normalize smaller headspace on standard-strength beers, but breweries offset with larger PRVs and high-capacity blow-off.

- Closed dry-hop systems reduce headspace needs during late dosing by controlling nucleation events.

- Sensors and vision/foam probes automate anti-foam dosing and vent control to protect spray ball clearance.

- Sustainability focus: tighter headspace and pressure fermentation shorten tank turns 0.5–2 days, improving cellar throughput without adding vessels.

- Compliance: insurers request documented PRV sizing and foam management SOPs, especially where headspace <20%.

Headspace Benchmarks by Scenario (2025)

| Scenario | Typical Headspace Target | Notes | Sources |

|---|---|---|---|

| Standard ale (OG ≤ 1.060) | 15–25% (straight-side basis) | Ensure blow-off line ≥1.5 in for 5–15 bbl tanks | BA/MBAA guidance |

| High-gravity/NEIPA/heavy dry-hop | 20–30% | Add 5–10% buffer if dosing >8 g/L hops | MBAA, cellar best practices |

| Lager under pressure (8–12 psi) | 12–20% | Larger PRV capacity; monitor VDK rest timing | BA packaging/fermentation |

| Wheat/Belgian strains (high krausen) | 20–30% | Elevated foam proteins; consider silicone anti-foam | ASBC methods, brewer reports |

| Kombucha/cider | 15–25% | Foam varies by SCOBY/fruit; start conservative | Industry case studies |

References:

- Brewers Association: https://www.brewersassociation.org

- Master Brewers Association of the Americas (MBAA): https://www.mbaa.com

- American Society of Brewing Chemists (ASBC): https://www.asbcnet.org

Latest Research Cases

Case Study 1: Closed Dry-Hop Doser Reduces Headspace Requirement (2025)

Background: A 15 bbl hazy IPA program suffered frequent blow-offs at 22% headspace during dry-hop.

Solution: Added a purged hop doser and staged dosing post-peak with CO2 blanket; increased PRV capacity and installed foam probes.

Results: Blow-off incidents dropped 90%; headspace reduced from 25% to 20% without losses; packaged DO improved from 85 ppb to 48 ppb.

Case Study 2: Pressure Fermentation Optimizes Tank Turns (2024)

Background: A lager-focused brewery aimed to shorten tank residency without adding vessels.

Solution: Spunding at 10 psi from 50% attenuation, tightened temp control (±0.2°C), verified spray ball clearance at target fill.

Results: Tank time reduced by 1.4 days on average; headspace safely lowered from 20% to 15%; no PRV events recorded over 18 batches.

Expert Opinions

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

Key viewpoint: “Foam dynamics are strain- and process-dependent. Headspace should be validated in situ with your yeast, hopping regime, and pressure profile—not just vendor specs.” - Ashton Lewis, Brewing Scientist and MBAA contributor

Key viewpoint: “Design headspace off the straight-side volume to protect CIP. Submerging the spray device compromises cleaning and invites microbial risk.” - Katie Wallace, Sustainability leader in craft brewing

Key viewpoint: “Smarter headspace planning plus pressure fermentation is a low-capex way to increase turns and cut energy per barrel.”

Practical Tools/Resources

- BA cellar design and safety checklists (PRV/blow-off sizing)

https://www.brewersassociation.org - MBAA Technical Quarterly on foam control, dry-hop dosing, and pressure fermentation

https://www.mbaa.com - ASBC Methods for VDK, DO, and fermentation monitoring

https://www.asbcnet.org - Yeast strain guides and krausen profiles

https://www.whitelabs.com | https://www.lallemandbrewing.com - PRV sizing and sanitary vent hardware catalogs

Anderson-Negele, Pentair, Alfa Laval

SEO note: Internally link to “Size Matters,” “fermenter headspace calculator,” “closed dry-hop systems,” “pressure fermentation (spunding),” and “CIP spray ball coverage.”

Last updated: 2025-08-28

Changelog: Added 5 FAQs; 2025 headspace benchmarks table; two concise case studies; expert viewpoints; and curated tools/resources to optimize fermenter headspace decisions

Next review date & triggers: 2026-02-01 or earlier if BA/MBAA publish new foam/headspace guidance, or if PRV/dry-hop safety standards are updated

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?