Distillation Equipment

Thank you for visiting the dedicated YoLong Distillery Equipment Information page. When it comes to distillation, we understand you need the kind of premium quality product you can rely on to get the job done flawlessly and reliably every time. At YoLong, we focus on developing distillation equipment you can depend on forever. Our unique combination of beautiful, careful fabrication, helpful custom design, easy installation, and ‘always there for you’ customer service has made us the go-to manufacturers for micro or craft distilleries, home still kits, and commercial stills, deliverable anywhere in the world.

Our goal here is to provide you with high-quality, functional distilling equipment at a better price than our competitors. As a professional manufacturer of world-class products, YoLong has specialized in the fabrication, installation, and upgrading of specialist brewery and beverage equipment for almost 15 years. The preparation of custom-made copper and stainless steel vessels, etc. has long been our chosen area of expertise, and now we have added making distilling equipment to our inventory of high-grade products.

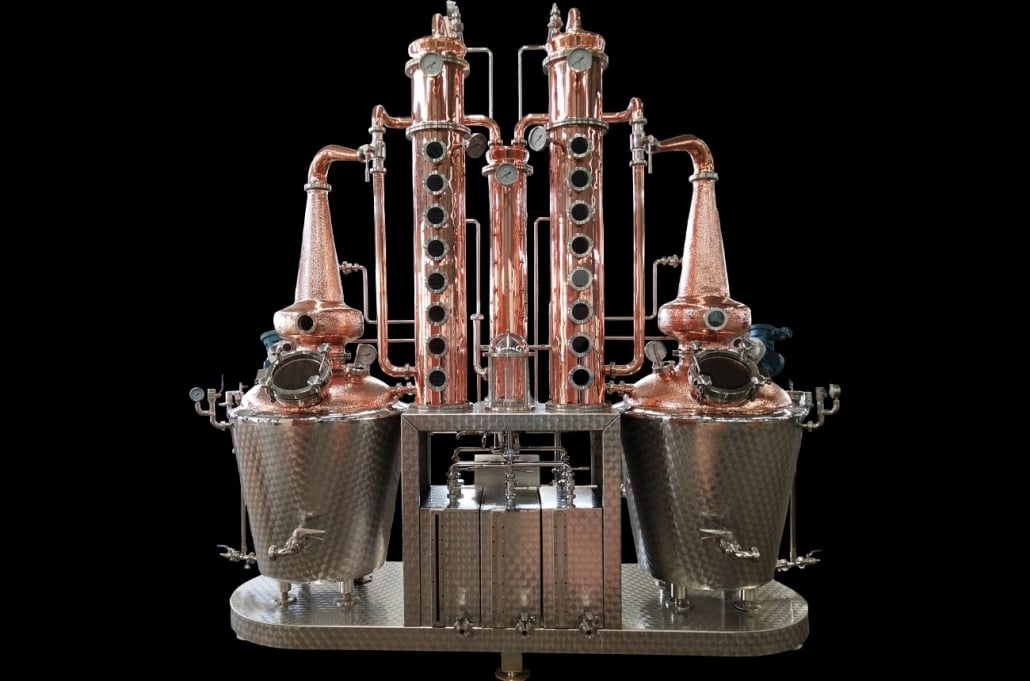

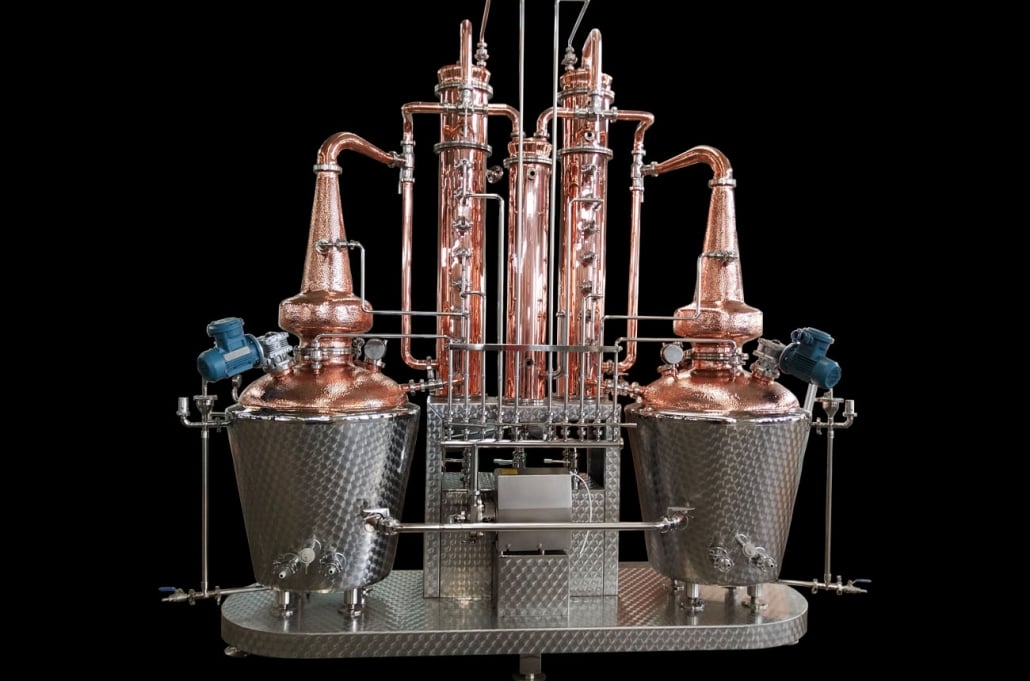

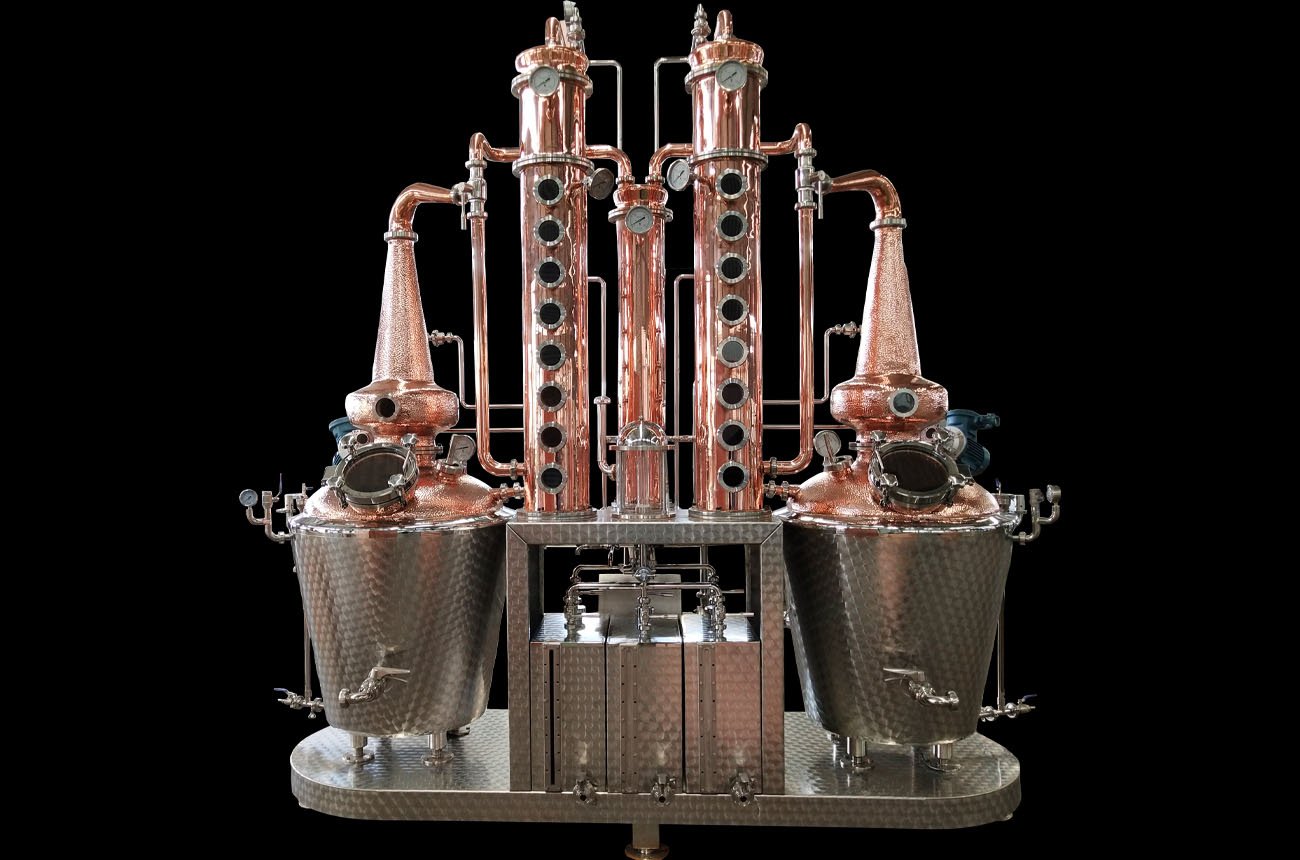

high quality distillery equipment

high quality distillery equipment distillery equipment

distillery equipment Pot Still

Pot Still port still

port still mixer

mixer distillery columns

distillery columns condensor

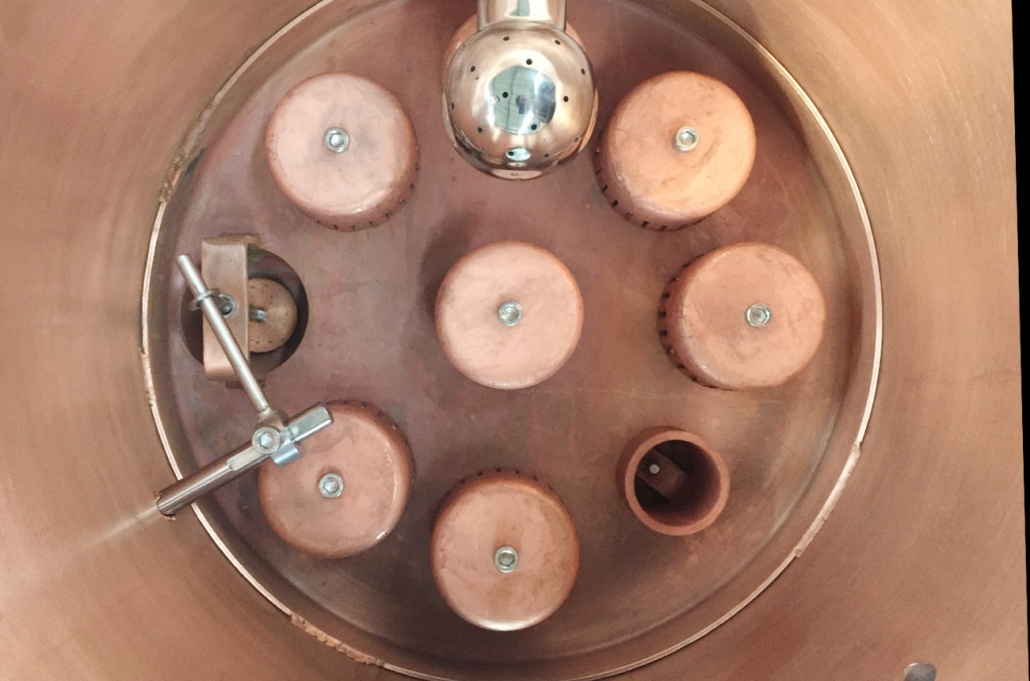

condensor Bubble Caps

Bubble Caps

As recognized masterful crafters of copper brewing equipment, this places us in the best position to launch into producing the beautiful copper work necessary to make the best distillery equipment. As distilling equipment is fabricated from copper and stainless steel, we are perfectly placed to be able to manufacture the kind of distillery equipment that not only works perfectly but also looks amazing.

YoLong is world renowned as producers rich with experience in copper fabrication. That’s why YoLong custom-made, high-quality craft distilling equipment is sure to set your operation apart from the rest.

Our mission is to innovate and improve – not just produce. Our premium grade distillation equipment and accessories are the preferred choice of many brewers all over the world. This comes down to the fact that YoLong prides itself on being the customer’s best resource for planning, design, fabrication, management, and also seamlessly delivers the successful execution of each unique brewery project every time!

Pot Still

A pot still is used in the production of many of the world’s most popular spirits. Where would the international and traditional spirit industry be without single malt scotch, cognac, rum, and mezcal? A Pot Still is essential as the basis of any classic batch distillation. What is batch distillation? The process involves a specified amount of liquid going into the still pot and distilling into spirit. Then the leftover dregs are dumped, the still gets cleaned out, and the whole process begins anew.

The function of the pot still starts, fittingly enough, inside the pot itself. The pot is a large tub-like base to which the rest of the components attach themselves. This is where the liquid about to be distilled starts its transformative journey. The pot may be heated by a variety of different methods. This can include a steam jacket lining the outside walls of the pot or even a steam coil inside the pot itself.

The pot still usually comes with the following fittings:

Distillery Equipment Accessories