Production Process and Manufacture of Cellar Tanks With International Standard Pressure Certification

Any manufacturer of brewery equipment must provide different pressure certification for both fermentation tanks and brite beer tanks. It is dependent on each country or region’s regulations and requirements, such as:

- AS1210 certificates (Australia Standard Pressure Tanks)

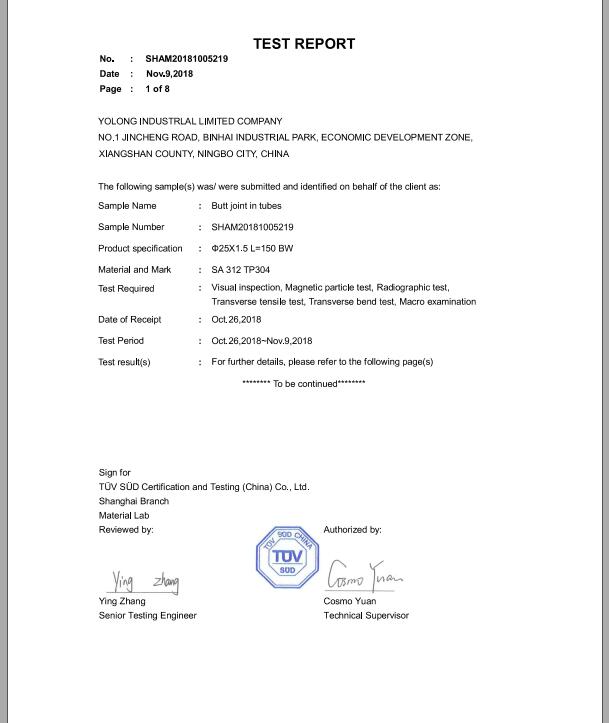

- PED /TUV certificates (European Union standard pressure tanks)

- ASME certificates (US, Canada required pressure tank certification)

YoLong manufacture the highest quality, best priced craft beer pressure vessels that strictly follow the applications and procedures necessary to ensure each country’s certification requirements are met.

YoLong’s Fermentation Vessel is the most popular pressure vessel ordered by breweries, both nationally and internationally. Pressure vessels are used during the conversion of wort into beer. Many overseas government health and safety departments require pressure vessel and equipment certification to accompany every new order – especially when a new brewery is being established.

At YoLong, we supply all relevant PED certification craft brewery owners need in order to import our fermenters. Additionally, you will be able to check the manufacturing process and equipment standardization methods used to make your pressurized tank in the paperwork we make available to you.

Ⅰ. How Pressure Vessels Are Manufactured According to Certified Methods

During the manufacture, production, and shipping of an international standard pressure vessel, we apply the relevant methods pertaining to the country for which the pressure vessel is bound. Besides our international standard production, we also supply all the pertinent documents you will need, and prepare them in advance.

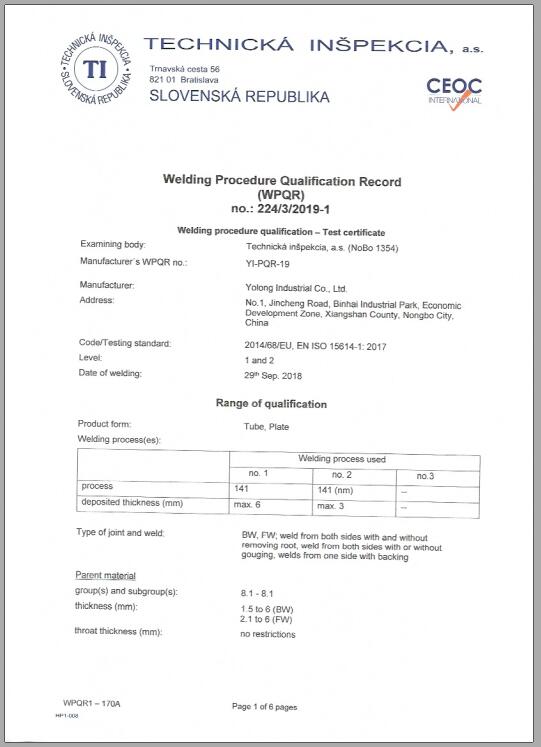

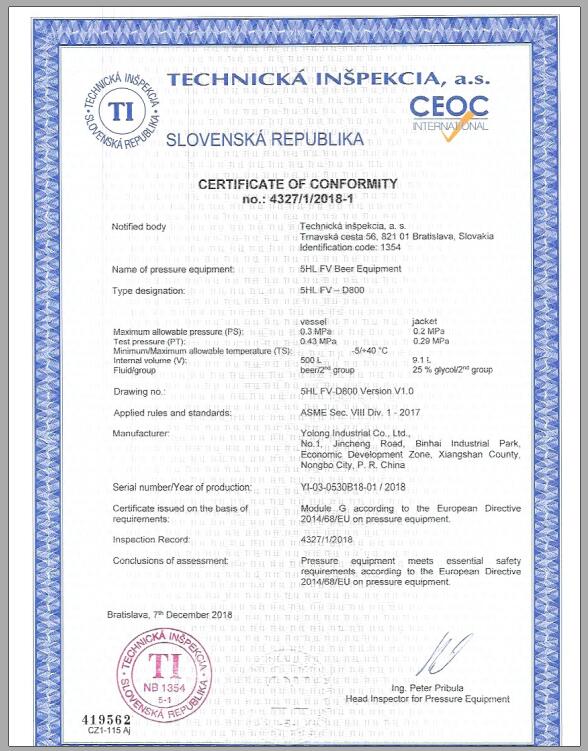

Below is the PED documentation and application required during the production process of a YoLong fermentation vessel.

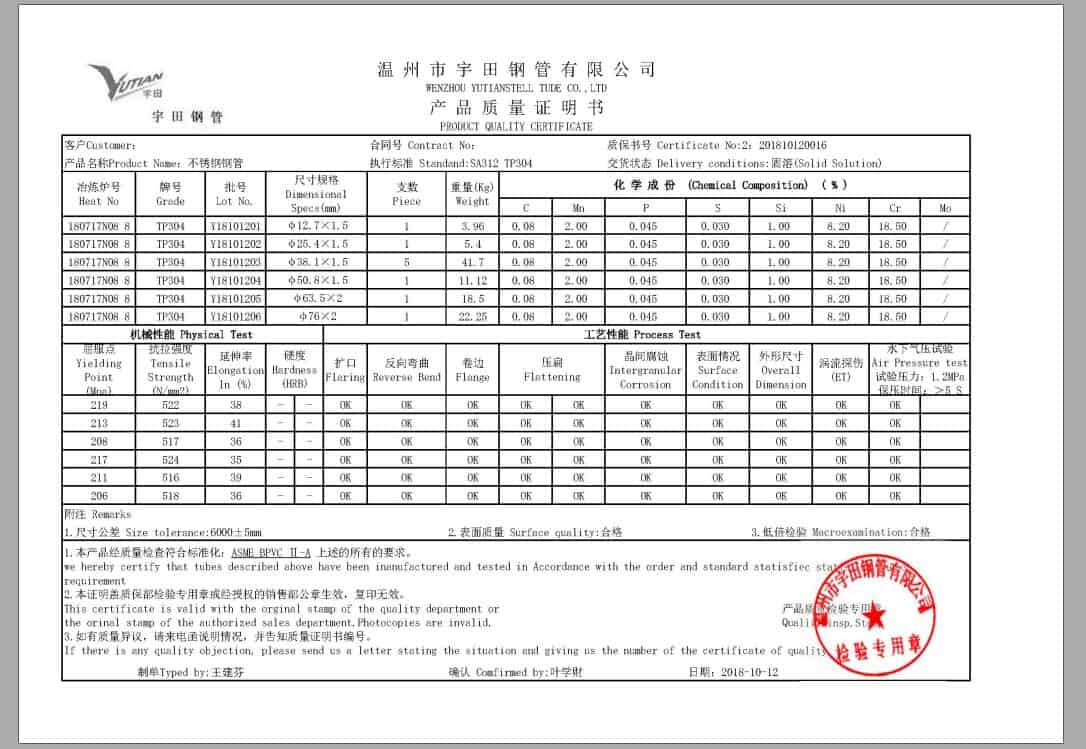

- 1. Fermenter drawings 2. Calculation Sheet 3. Design and Registration 4. Weld Seam Identification Card 5. WPS 6. WPQR 7. Dimension Inspection Report 8. Dished Head Certificate(1)Head Specifications Report(2)Quality Certificates(3)Quality Certification of Sheet Material 9. Stainless Steel Sheet Quality Certificates 10. Quality certification of seamless steel tube 11. Pressure Testing Report 12. Operation Manual 13. Welding evaluation report 14. Statement of Inspection institution 15.PED Certificates

WPQR

5HL FV PED Certificates

The documents above are ones you need to know in advance. This is so you are assured the fermentation tanks you ordered adhere to the regulations of the country where your brewery is based. This will greatly assist you with inspections and customs. The documents will also give you a better understanding of your pressure tank order, a big benefit when it comes to installation and transport. The YoLong engineers complete the drawings, and once you have signed off on them, we begin production of your fermenters or brite tanks.

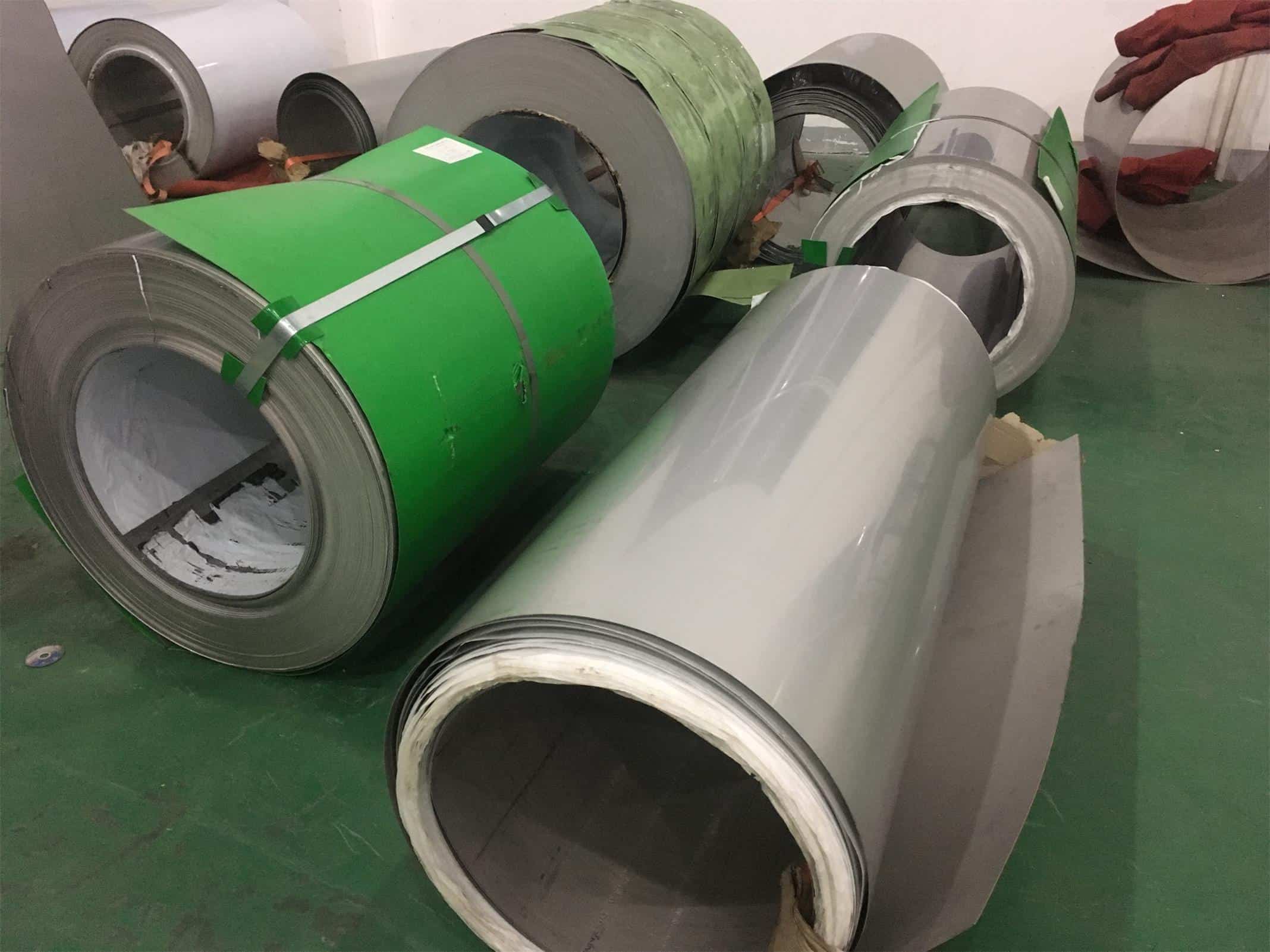

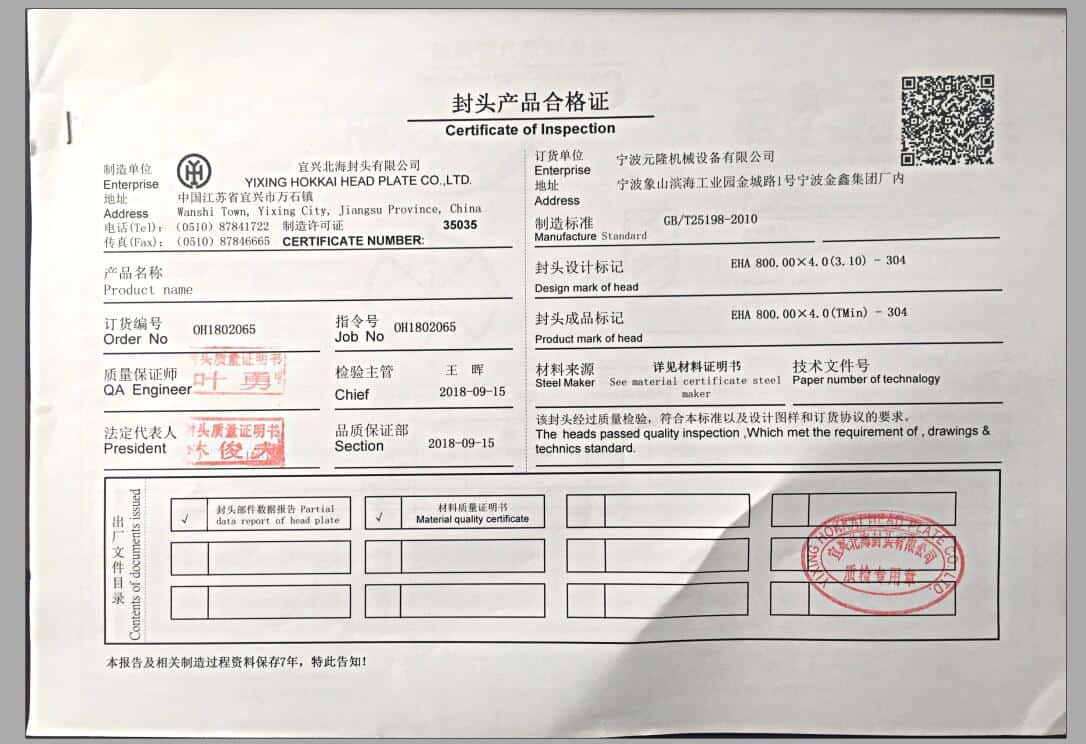

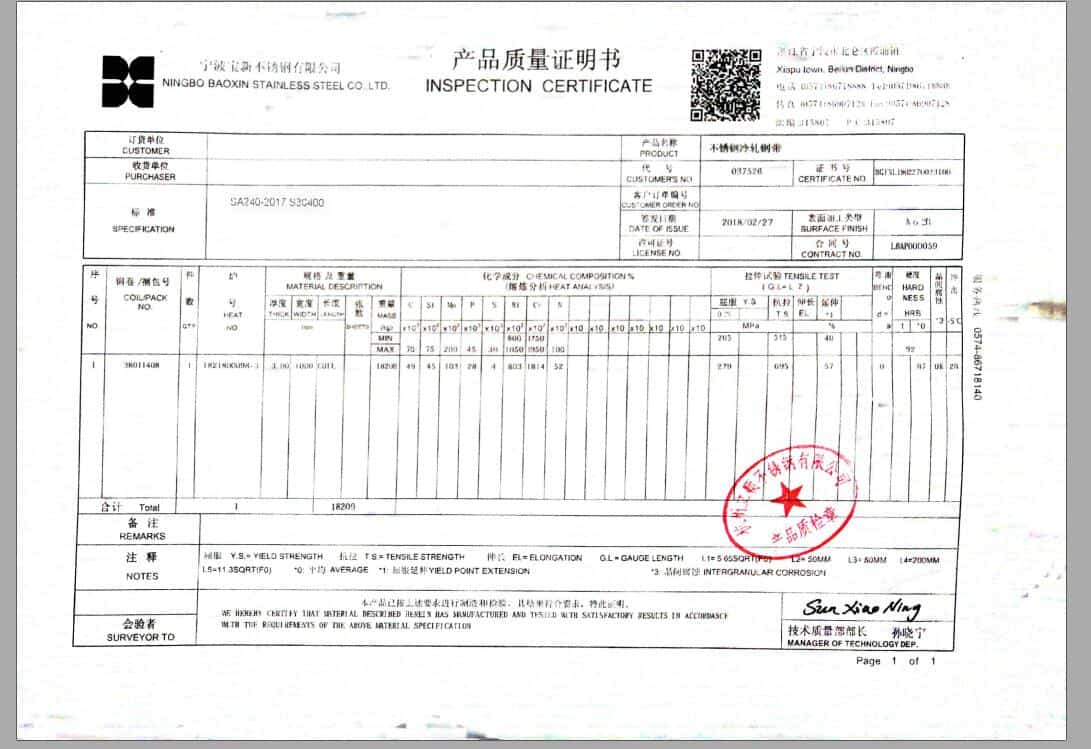

II. Raw Material Purchasing & Quality Certification

Complete, international standard pressure certification also necessitates quality inspection and certification for all purchased materials. Every YoLong supplier also provides us with relevant documents and certification. We choose our raw material suppliers carefully, and they are required to produce only the highest quality, international standard materials and parts, such as: certification for heads, stainless steel sheets, pipes, etc. Materials we order from our suppliers are all quality-assured by inspection. Additionally to the materials and parts certification, a YoLong inspector ensures our suppliers maintain their high-quality production of microbrewery parts and equipment, and it is this strict control that continues to promote the outstanding YoLong reputation for high-quality with our customers.

Certificates of Head

Certificates of Stainless Steel Sheet

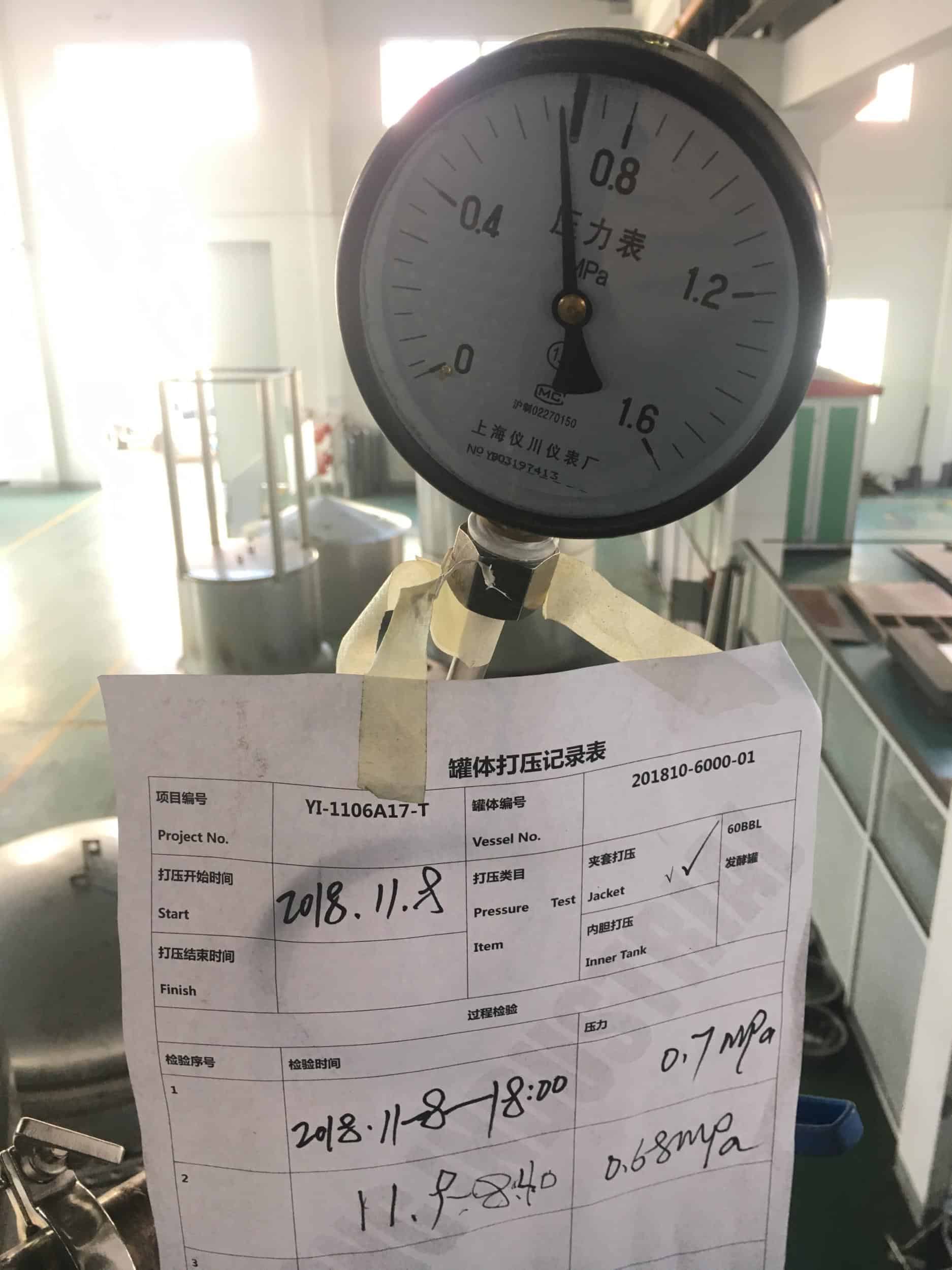

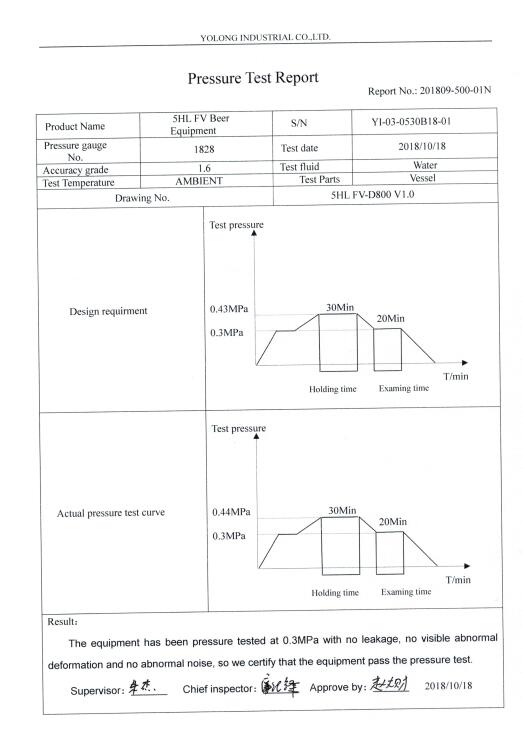

III. Pressure Vessel Producing/Process Inspection

When the previously mentioned jobs are complete, we begin production of the brewery tanks. Throughout the process, we maintain the highest manufacturing quality to ensure each step in the international standard inspection is implemented and passed. This is especially important when it comes to the pressure testing and welding seam testing. Every pressure vessel we produce – fermentation tanks for example – has 7-bar cooling jacket pressure sustained for at least 24-hours. This method of production guarantees the cooling jacket on the jacketed fermentation vessels will never experience leakage.

Inner Shell Pressure Test(2Bar)

Pressure Test Report

Welding Seams

Pressure Test Report

IV. Obtaining Certification for YoLong Pressure Tanks

After each YoLong tank is completed to our satisfaction, we submit manual labor reports, welding certificates, etc. to the relevant authorities for international pressure certification approval.

It is this meticulous attention to detail which allows YoLong to supply every pressure tank we manufacture with Pressure Certificates

Please have a look at our Fermentation Tank and Brite Beer Tank specs.

Please feel free to contact us, if you would like to know more about our brewery equipment or pressure vessels.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!