Production Process and Manufacture of Cellar Tanks With International Standard Pressure Certification

Any manufacturer of brewery equipment must provide different pressure certification for both fermentation tanks and brite beer tanks. It is dependent on each country or region’s regulations and requirements, such as:

- AS1210 certificates (Australia Standard Pressure Tanks)

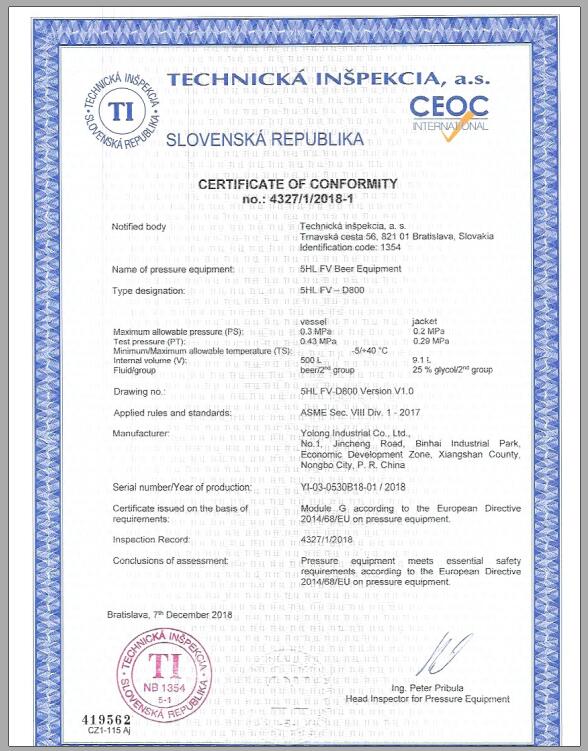

- PED /TUV certificates (European Union standard pressure tanks)

- ASME certificates (US, Canada required pressure tank certification)

YoLong manufacture the highest quality, best priced craft beer pressure vessels that strictly follow the applications and procedures necessary to ensure each country’s certification requirements are met.

YoLong’s Fermentation Vessel is the most popular pressure vessel ordered by breweries, both nationally and internationally. Pressure vessels are used during the conversion of wort into beer. Many overseas government health and safety departments require pressure vessel and equipment certification to accompany every new order – especially when a new brewery is being established.

At YoLong, we supply all relevant PED certification craft brewery owners need in order to import our fermenters. Additionally, you will be able to check the manufacturing process and equipment standardization methods used to make your pressurized tank in the paperwork we make available to you.

Ⅰ. How Pressure Vessels Are Manufactured According to Certified Methods

During the manufacture, production, and shipping of an international standard pressure vessel, we apply the relevant methods pertaining to the country for which the pressure vessel is bound. Besides our international standard production, we also supply all the pertinent documents you will need, and prepare them in advance.

Below is the PED documentation and application required during the production process of a YoLong fermentation vessel.

- Fermenter Drawings

- Calculation Sheet

- Design and Registration

- Weld Seam Identification Card

- WPS (Welding Procedure Specification)

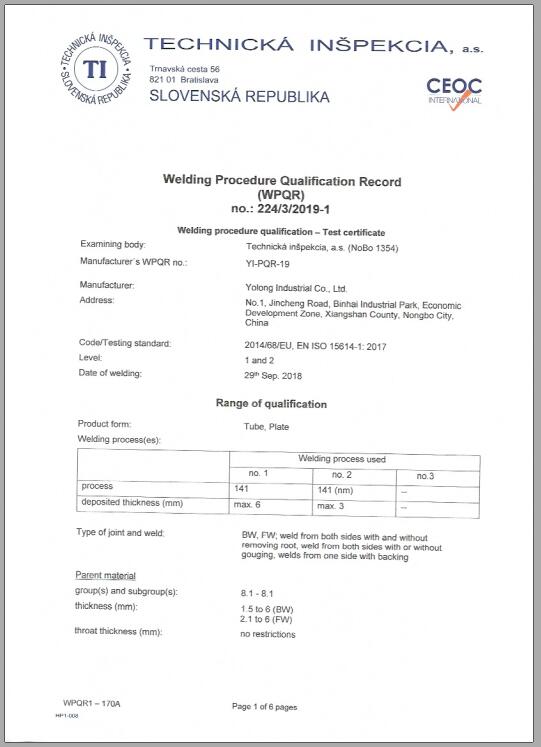

- WPQR (Welding Procedure Qualification Record)

- Dimension Inspection Report

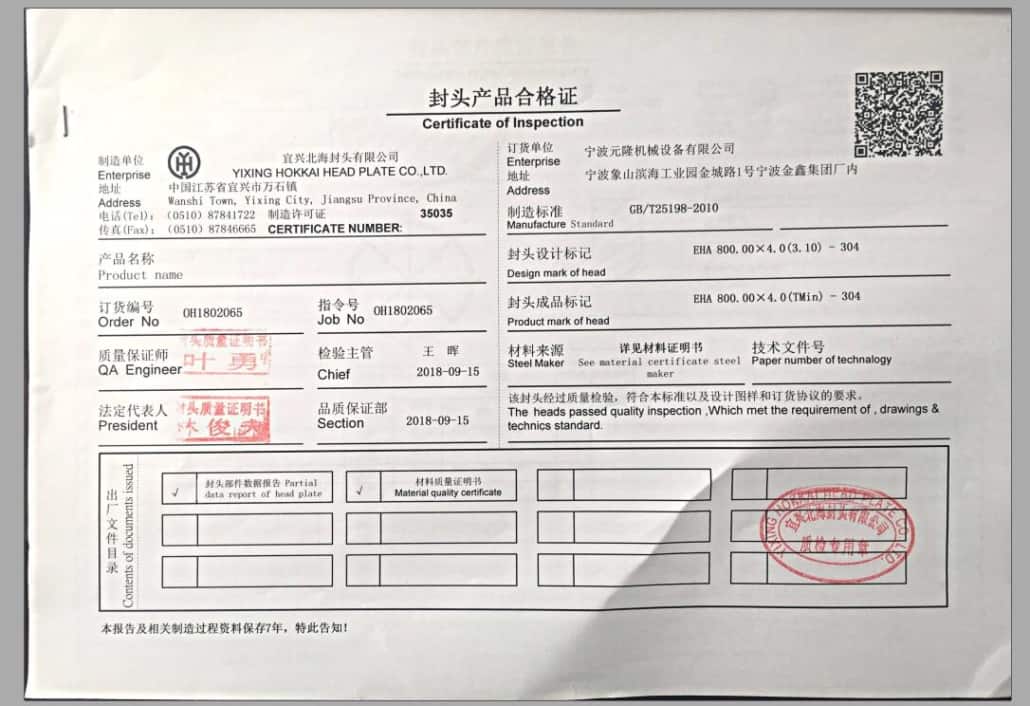

- Dished Head Certificate: (1) Head Specifications Report (2) Quality Certificates (3) Quality Certification of Sheet Material

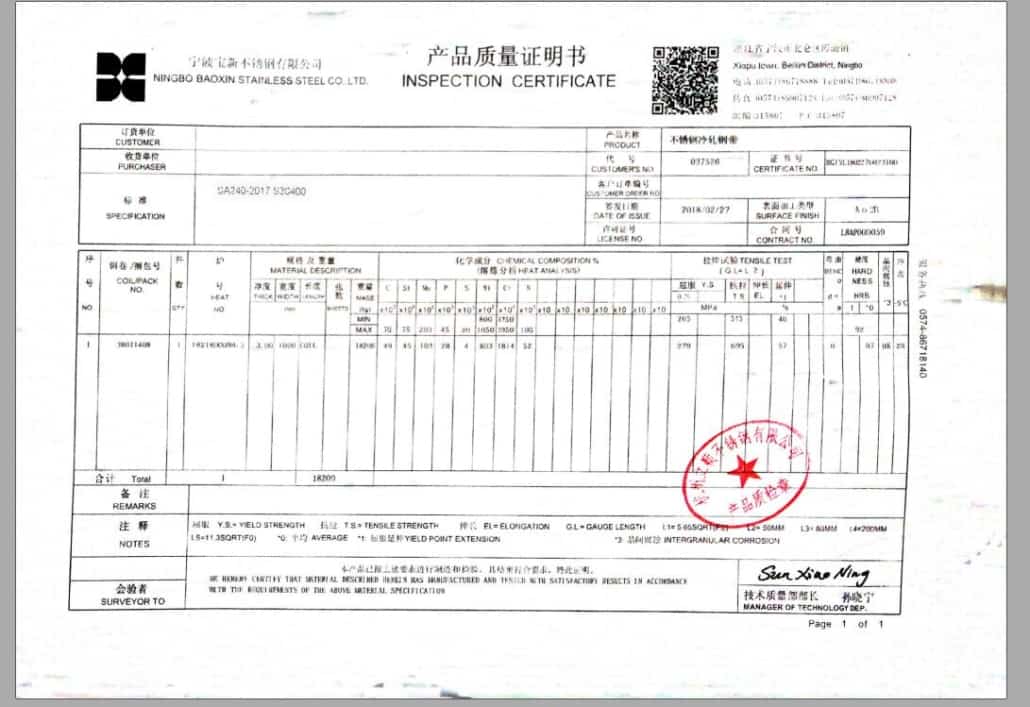

- Stainless Steel Sheet Quality Certificates

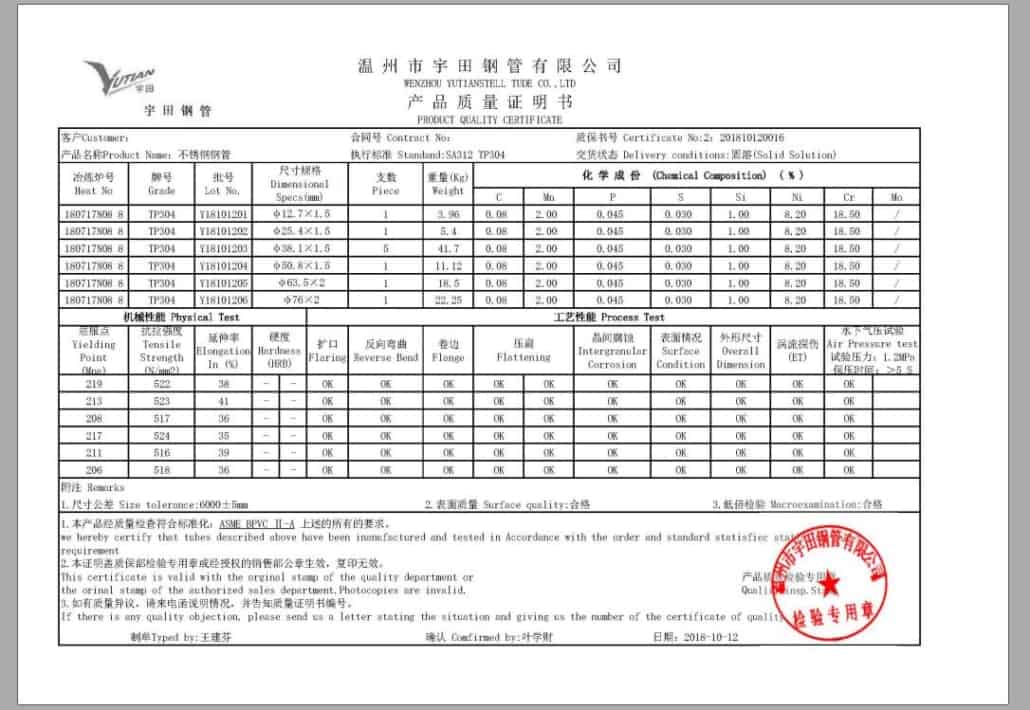

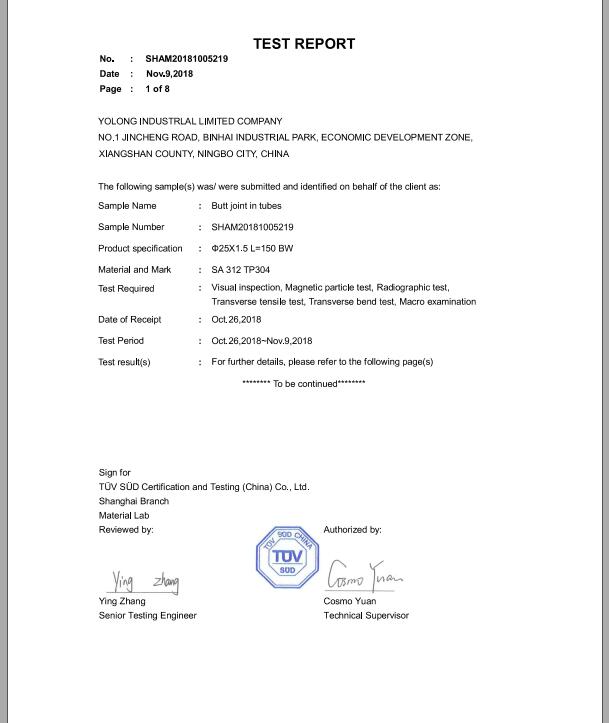

- Quality Certification of Seamless Steel Tube

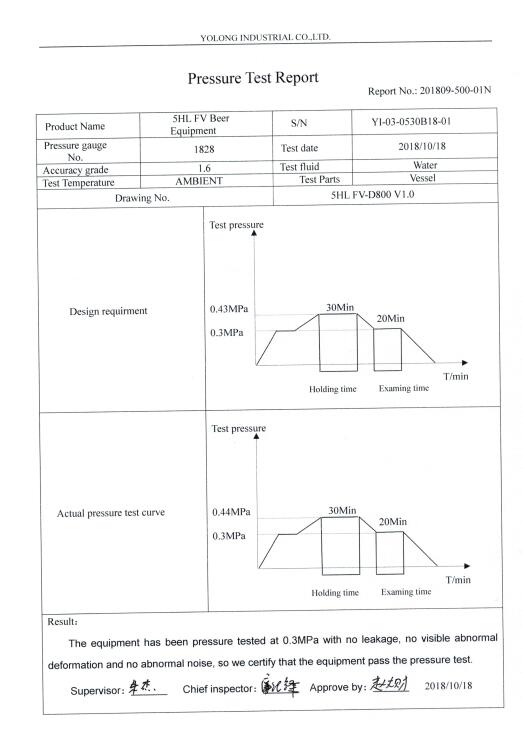

- Pressure Testing Report

- Operation Manual

- Welding Evaluation Report

- Statement of Inspection Institution

- PED Certificates

WPQR

5HL FV PED Certificates

II. Raw Material Purchasing & Quality Certification

Complete, international standard pressure certification also necessitates quality inspection and certification for all purchased materials. Every YoLong supplier also provides us with relevant documents and certification. We choose our raw material suppliers carefully, and they are required to produce only the highest quality, international standard materials and parts, such as: certification for heads, stainless steel sheets, pipes, etc. Materials we order from our suppliers are all quality-assured by inspection. Additionally to the materials and parts certification, a YoLong inspector ensures our suppliers maintain their high-quality production of microbrewery parts and equipment, and it is this strict control that continues to promote the outstanding YoLong reputation for high-quality with our customers.

III. Pressure Vessel Producing/Process Inspection

When the previously mentioned jobs are complete, we begin production of the brewery tanks. Throughout the process, we maintain the highest manufacturing quality to ensure each step in the international standard inspection is implemented and passed. This is especially important when it comes to the pressure testing and welding seam testing. Every pressure vessel we produce – fermentation tanks for example – has 7-bar cooling jacket pressure sustained for at least 24-hours. This method of production guarantees the cooling jacket on the jacketed fermentation vessels will never experience leakage.

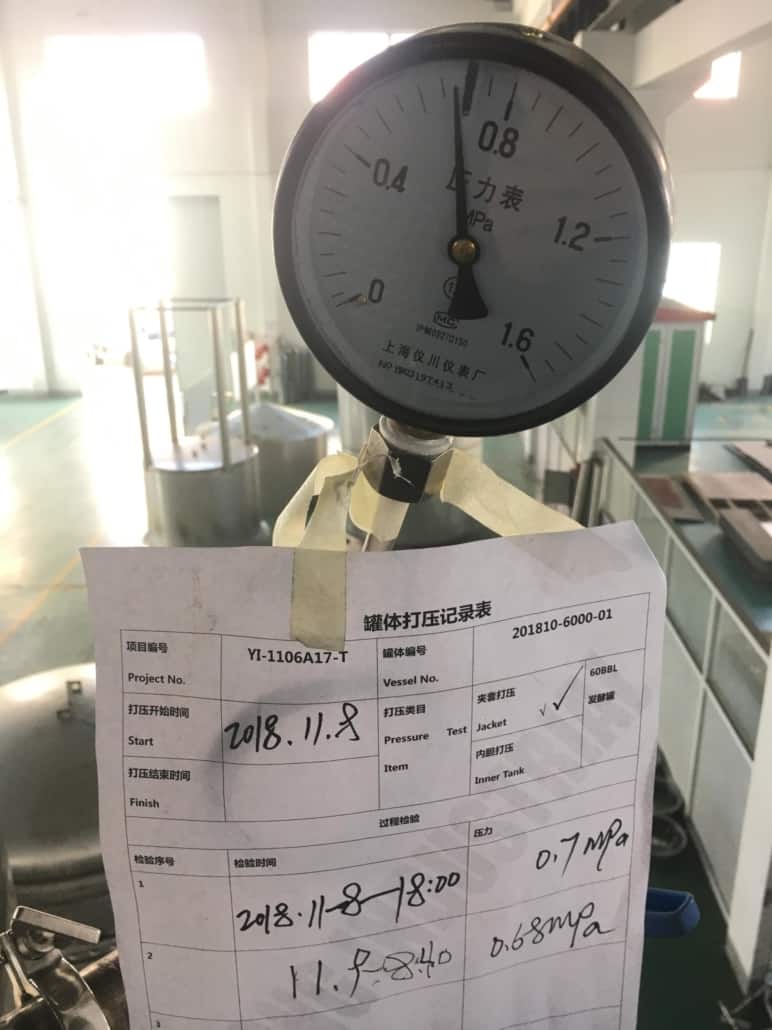

Jacket Pressure Test (7Bar)

pressure test report

Inner Shell Pressure Test (2Bar)

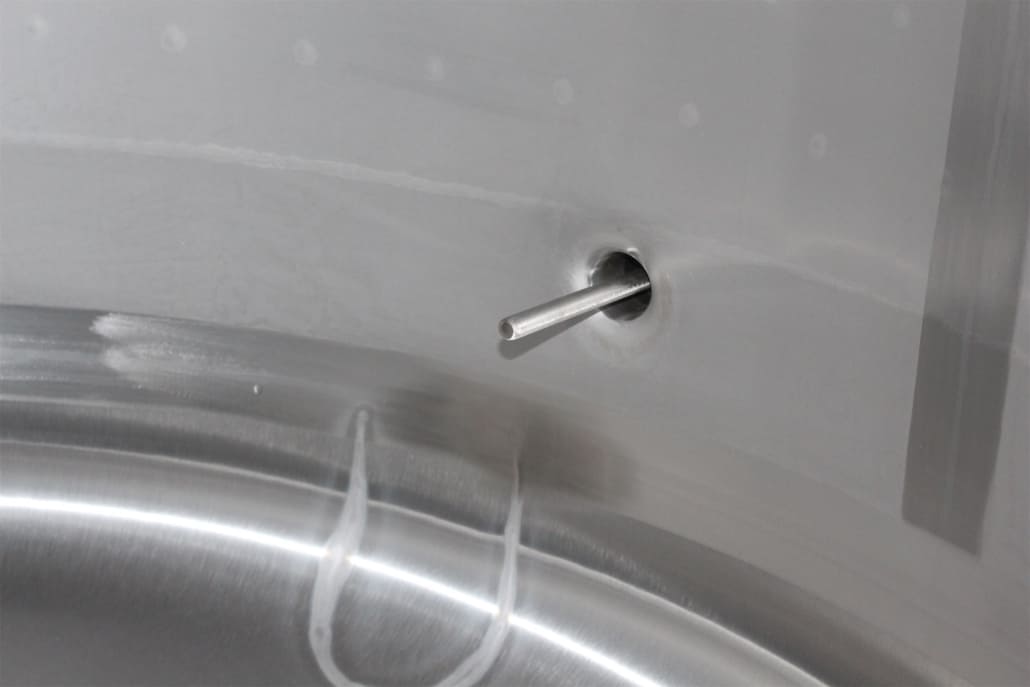

Inner Welding Polish

Inner Seams Polishing

PQR

IV. Obtaining Certification for YoLong Pressure Tanks

After each YoLong tank is completed to our satisfaction, we submit manual labor reports, welding certificates, etc. to the relevant authorities for international pressure certification approval.

It is this meticulous attention to detail which allows YoLong to supply every pressure tank we manufacture with Pressure Certificates

Please take a look at our Fermentation Tank and Brite Beer Tank specs.

Please feel free to contact us, if you would like to know more about our brewery equipment or pressure vessels.

Frequently Asked Questions (FAQ)

1) What pressure ratings are typical for brewery Cellar Tanks with international certification?

- Fermentation unitanks commonly carry 1.5–2.0 bar working pressure (WP) with PRVs set accordingly; jackets are hydrotested (e.g., 7 bar for 24 h). Verify ASME Section VIII or CE-PED approvals and nameplate data.

2) Which documents must accompany CE-PED certified Cellar Tanks on delivery?

- Expect design drawings, calculation sheets, material certificates (EN 10204 3.1), WPS/WPQR, NDE records, pressure test reports, operating manual, Declaration of Conformity, and CE mark/plate.

3) How are welds on pressurized Cellar Tanks qualified and verified?

- Welders are qualified to WPS/WPQR; seams receive NDE (dye penetrant for austenitic SS, radiography/UT where required). Post-weld passivation and Ra verification ensure hygienic performance.

4) What internal surface finish is recommended for hygienic Cellar Tanks?

- Specify ≤0.6–0.8 μm Ra on wetted surfaces, fully pickled/passivated. Request weld maps and boroscope inspections to confirm shadow-free, crevice-minimized construction.

5) How often should pressure relief valves and gauges be tested?

- Calibrate/test PRVs and gauges at least annually or per local code/insurer requirements. Keep traceable records tied to the vessel serial number for audits.

2025 Industry Trends for Certified Cellar Tanks

- Higher-pressure unitanks (up to 2.0–3.0 bar WP) enabling pressure fermentation and in-vessel carbonation.

- Digital traceability: QR-linked material certs, weld maps, and lifecycle service logs.

- Enhanced hygienic design: shadowless manways, orbital-welded spools, and automated CIP validation.

- Sustainability: thicker insulation, efficient dimple jackets, and heat recovery on CIP/hot water.

- Global compliance harmonization: more OEMs offering dual-marked ASME/CE-PED documentation packages.

2025 Benchmarks and Stats

| Metric | Typical Range/Benchmark (2025) | Notes / Source |

|---|---|---|

| Working pressure spec (FV/BBT) | 1.5–2.0 bar (common); up to 3.0 bar (premium) | OEM specs; ASME/PED datasheets |

| Jacket hydrotest | 6–8 bar for ≥24 h | Factory FAT records |

| Internal surface finish (Ra) | ≤0.6–0.8 μm on wetted surfaces | EHEDG/MBAA guidance |

| Inline sensor adoption on new tanks | 45–65% (DO, gravity) | Integrator/OEM reports 2025 |

| Insulation thickness (FV/BBT) | 50–100 mm PU/PIR typical | OEM tech sheets |

| Documentation completeness score at FAT | >95% target (drawings, certs, NDE, test) | Third-party inspection KPIs |

Selected references:

- ASME Section VIII, Pressure Vessels: https://www.asme.org

- EU Pressure Equipment (CE-PED): https://single-market-economy.ec.europa.eu

- EHEDG Hygienic Design: https://www.ehedg.org

- MBAA Technical resources: https://www.mbaa.com

- ASBC Methods (DO/CO2/VDK): https://www.asbcnet.org

Latest Research Cases

Case Study 1: Dual-Certified Cellar Tanks to Streamline Export (2025)

Background: A brewery planned multi-region distribution requiring both ASME and CE-PED compliant vessels.

Solution: Sourced dual-marked unitanks with unified document packs (WPS/WPQR, 3.1 certs, NDE, hydrotests) and QR-coded traceability.

Results: Customs clearance time reduced 40%; insurer accepted unified inspection logs; commissioning completed one week earlier.

Case Study 2: Low-DO Upgrade via Certified Accessories (2024)

Background: Shelf-life issues traced to oxygen ingress during transfers.

Solution: Installed certified PRVs, shadowless manways, orbital-welded hard piping, and inline DO sensors at outlet nozzles; validated CIP endpoints via conductivity.

Results: Knockout DO <30 ppb; package DO <40 ppb; returns for staling dropped 60% over two quarters.

Expert Opinions

- Charlie Bamforth, Professor Emeritus of Malting & Brewing Science, UC Davis

“Certified Cellar Tanks are only as good as their cleanability. Smooth finishes and validated CIP coverage protect flavor stability.” - Laura Ulrich, Senior Brewer and Industry Educator

“Pressure capability plus reliable instrumentation turns tanks into process tools—spunding, carb, and tighter QA from the same vessel.” - Eric Toft, Brewmaster, Privatbrauerei Schönram

“Documentation matters. Material certs and test records build confidence and simplify audits years after installation.”

Practical Tools/Resources

- ASME Boiler & Pressure Vessel Code overview: https://www.asme.org

- EU Pressure Equipment (PED) guidance: https://single-market-economy.ec.europa.eu

- EHEDG guidelines on hygienic welds and tank design: https://www.ehedg.org

- MBAA Technical Quarterly (CIP, hygienic design, oxygen control): https://www.mbaa.com

- ASBC Methods (DO/CO2/VDK validation): https://www.asbcnet.org

SEO tip: Internally link the anchor text “Cellar Tanks” to detailed pages on PED/ASME documentation, CIP validation, and low-DO transfer practices to strengthen topical authority and conversions.

Last updated: 2025-09-05

Changelog: Added 5 FAQs on certification and hygiene, 2025 trends with benchmark table and sources, two recent case studies, expert viewpoints, and curated standards/resources for certified Cellar Tanks.

Next review date & triggers: 2026-02-01 or earlier if ASME/PED standards revise, EHEDG issues new tank guidance, or sensor/traceability adoption materially shifts best practices.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?