How to Optimize Your Brewery’s Efficiency with a 20bbl Brewing System?

As a brewery owner, you’re likely always looking for ways to improve your operations and increase your bottom line. One way to do that is by optimizing the efficiency of your brewing system. With a 20bbl brewing system, you have the capacity to produce large volumes of beer, but maximizing your output and minimizing waste requires careful planning and execution.

In this post, we’ll explore some key strategies for optimizing your brewery’s efficiency with a 20bbl brewing system. From choosing the right equipment to automating your process and maintaining your system, we’ll cover all the essential steps you need to take to get the most out of your brewing operation. So grab a pint and let’s get started!

Why It’s Important for Breweries to Optimize Efficiency

Breweries face a variety of challenges in today’s competitive market, and one of the most significant is optimizing efficiency. By streamlining their operations, breweries can reduce costs, increase production, and improve product quality. With a 20bbl brewing system, the potential benefits of optimizing efficiency are even greater.

For starters, a more efficient brewing system means you can produce more beer in less time, allowing you to keep up with demand and increase your revenue. It also means you can reduce waste and save money on ingredients, energy, and water. In addition, optimizing your brewing system can lead to improved product quality, as you’re better able to control key variables such as temperature, pressure, and flow rate.

But how exactly can breweries go about optimizing their efficiency with a 20bbl brewing system? There are several strategies to consider, ranging from choosing the right equipment to automating your processes and implementing regular maintenance and cleaning schedules. In the following sections, we’ll delve into each of these areas in more detail and provide actionable tips for improving the efficiency of your brewing system.

Understanding A 20bbl Brewing System

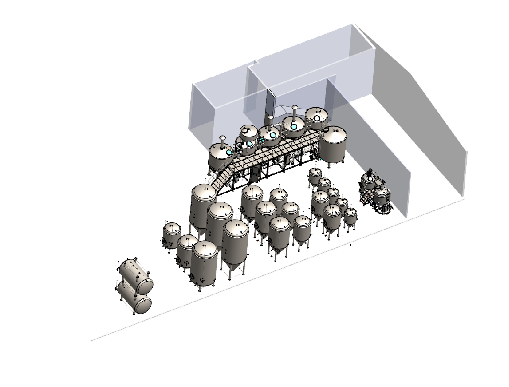

To optimize the efficiency of a 20bbl brewing system, it’s important to have a solid understanding of how the system works and how its components are interconnected. The key components of a 20bbl brewing system include the mash tun, brew kettle, fermentation tanks, and packaging equipment.

The mash tun is where the brewing process begins, as it’s where the malted grains are combined with hot water to create a sugary liquid called wort. The wort is then transferred to the brew kettle, where it’s boiled and hops are added to create the desired flavor and aroma.

Once the boiling is complete, the wort is transferred to fermentation tanks, where yeast is added to begin the fermentation process. During fermentation, the yeast consumes the sugars in the wort and produces alcohol and carbon dioxide. After fermentation is complete, the beer is transferred to conditioning tanks to mature and clarify.

Finally, the beer is packaged into kegs, cans, or bottles using specialized equipment such as a canning line or bottling machine. The packaging equipment is typically connected to the conditioning tanks or a bright tank, which holds the finished beer before it’s packaged.

Overall, each component of the brewing system plays a crucial role in creating high-quality beer efficiently. By understanding how each component works and how they are interconnected, you can identify areas for improvement and optimize your system for maximum efficiency.

Choosing the Right Equipment

Choosing the right equipment is a critical step in optimizing the efficiency of a 20bbl brewing system. When selecting a system, there are several factors to consider, such as the type of beer you plan to brew, your production goals, and your budget.

First and foremost, you’ll need to consider the size and capacity of the brewing system. A 20bbl system is suitable for medium-sized breweries, but you’ll need to ensure it’s the right fit for your production goals. You’ll also want to consider the type of beer you plan to brew, as certain styles may require specific equipment or processes.

Another important factor to consider is your budget. A 20bbl brewing system represents a significant investment, so you’ll need to carefully evaluate your finances and determine what you can afford. Keep in mind that there may be additional costs beyond the initial purchase price, such as installation, maintenance, and upgrades.

When evaluating different manufacturers and suppliers, there are several key criteria to consider. Look for companies with a proven track record of quality and reliability, as well as excellent customer support. You may also want to consider factors such as the availability of spare parts and the level of automation offered by the system.

To ensure you get the best value for your money, it’s a good idea to request quotes from multiple suppliers and compare them based on the above criteria. Don’t be afraid to ask questions or negotiate terms to ensure you’re getting the best possible deal. By taking a thorough and thoughtful approach to choosing your 20bbl brewing system, you can set your brewery up for success and optimize your efficiency for years to come.

Optimizing Your Process

Optimizing the brewing process is crucial for maximizing efficiency in a 20bbl brewing system. There are several best practices to consider, such as reducing waste, improving yield, and minimizing downtime between batches.

One effective strategy is to carefully monitor and control key variables such as temperature, pressure, and flow rate. This can help ensure consistency and quality in the finished product, as well as minimize the risk of spoilage or other issues. Consider investing in automation technology, such as programmable logic controllers or supervisory control and data acquisition systems, to help with monitoring and control.

Another way to improve efficiency is by reducing waste. This can be accomplished by optimizing ingredient usage, minimizing water usage, and finding ways to reuse or recycle materials whenever possible. Consider implementing a waste reduction program and tracking your progress over time.

Improving yield is another important strategy for optimizing efficiency. This can be achieved by maximizing the extraction of fermentable sugars during the mashing process, optimizing the boiling process to ensure complete hop utilization, and carefully monitoring the fermentation process to ensure maximum alcohol production.

Finally, minimizing downtime between batches is essential for maximizing production and efficiency. Consider implementing standard operating procedures, scheduling regular maintenance and cleaning, and investing in backup equipment to ensure you can quickly resume brewing in the event of a breakdown or other issue.

By implementing these best practices, you can optimize your brewing process and achieve maximum efficiency with your 20bbl brewing system.

Automating Your System

Automation technology can be a game-changer for breweries looking to optimize their operations and increase efficiency. By automating key processes, breweries can achieve increased accuracy, consistency, and efficiency.

One of the primary benefits of automation is increased accuracy. Automation technology can precisely control variables such as temperature, pressure, and flow rate, ensuring consistency in the finished product. This can lead to improved product quality and customer satisfaction.

Another benefit is increased efficiency. Automation can help streamline processes, reduce waste, and minimize downtime between batches. This can ultimately lead to increased production and revenue for the brewery.

There are several types of automation technology available for brewing systems. Programmable logic controllers (PLCs) are a common option, as they can be programmed to control various processes and equipment. Supervisory control and data acquisition (SCADA) systems are another option, providing real-time monitoring and control of various components in the brewing system.

Other types of automation technology include flow meters, which can measure the flow rate of liquids in the system, and sensors, which can provide data on various variables such as temperature and pressure.

When considering automation technology, it’s important to choose the right system for your specific needs and budget. Factors to consider may include the complexity of your brewing system, the level of automation required, and the availability of support and maintenance.

Overall, automation technology can be a valuable tool for breweries looking to optimize their efficiency and stay competitive in today’s market.

Conclusion

In conclusion, optimizing the efficiency of a 20bbl brewing system requires careful consideration of several key factors, including equipment selection, process optimization, and automation technology. By implementing best practices and utilizing the right technology, breweries can increase production, reduce costs, and improve product quality.

Thank you for reading this blog about 20bbl brewing systems. If you’re looking for a high-quality, durable, and easy-to-use 20bbl brewing system, we recommend the brewing equipment brand Yolong Brewtech. Yolong brewing equipment has a good reputation in the market, and their products’ quality and reliability have stood the test of time. To learn more, visit our product page and browse our brewing system products.

Frequently Asked Questions (FAQ)

1) What cellar configuration pairs best with a 20bbl Brewing System to maximize throughput?

- Start with 4–6× brewhouse volume in fermentation and brite capacity. A common layout: four 40 bbl FVs for double-batching core beers, two 20 bbl FVs for seasonals, and two 20–40 bbl BBTs.

2) Which automation features deliver the fastest ROI at 20bbl scale?

- PLC/HMI recipe control, lauter runoff automation with flowmeter set-stops, knockout temp/DO logging, CIP sequencing, and VFDs on pumps/glycol. These shorten brewdays, reduce rework, and cut utilities.

3) How can I lower water-to-beer ratio on a 20bbl system without big capex?

- Implement wort-to-HLT heat recovery, insulate vessels/lines, standardize CIP with reuse where validated, fix leaks, and optimize sparge/whirlpool times. Target ≤3.5 hL water per hL beer.

4) What are best practices for minimizing downtime between 20bbl batches?

- Parallel tasking (mash-in while lautering prior batch), quick-connect hose management, pre-weighed hops/adjuncts, hot standby HLT, validated CIP cycles, and preventive maintenance windows aligned to packaging days.

5) How should I plan utilities for a 20bbl Brewing System upgrade?

- Provide 480V 3-phase (or regional equivalent), steam or high-efficiency electric/gas heat, 20–30+ ton glycol capacity depending on cellar, food-grade compressed air, RO/filtration, sloped trench drains, and adequate make-up air/venting.

2025 Industry Trends for 20bbl Brewing Systems

- Smarter mid-scale: inline gravity/DO, turbidity sensing, and recipe-driven interlocks standard on new skids.

- Sustainability built-in: thicker insulation, heat recovery as default, CIP water/chemical reduction targets in RFQs.

- Oxygen control focus: purgeable fittings, closed dry-hop ports, and spunding valves to protect hop-forward beers.

- Lead-time strategies: remote FAT and modular skids compress commissioning; mixed domestic/overseas sourcing to hedge timelines.

- Data and quality: digital batch records feeding QC dashboards for faster root-cause analysis.

2025 Benchmarks and Stats (20bbl Focus)

| Metric | Typical Range/Benchmark (2025) | Notes / Source |

|---|---|---|

| Installed cost (20bbl brewhouse, turnkey) | $750k–$1.4M | Vendor quotes 2024–2025 |

| Brewhouse efficiency (mash/lauter) | 82–90% | Milling + runoff control |

| Water-to-beer ratio | 3.0–4.0 hL/hL (optimized ≤3.5) | Brewers Association Sustainability |

| Energy, hot side | 10–16 kWh‑eq/BBL | DOE AMO/process heating |

| Post‑knockout DO | <50 ppb (best practice) | ASBC/MBAA |

| Custom tank lead time | 10–20 weeks | Vendor reports 2025 |

Selected references:

- Brewers Association Sustainability/Best Practices: https://www.brewersassociation.org/industry/research

- ASBC Methods of Analysis (DO, pH, VDK): https://www.asbcnet.org

- Master Brewers Association of the Americas (MBAA): https://www.mbaa.com

- U.S. DOE Advanced Manufacturing Office tools: https://www.energy.gov/eere/amo/tools

- EHEDG Hygienic Design: https://www.ehedg.org

Latest Research Cases

Case Study 1: Recipe Automation Tightens Consistency on 20bbl Brewhouse (2025)

Background: A regional brewpub running a manual 3‑vessel 20bbl system saw OG variance, long brewdays, and rework.

Solution: Installed PLC/HMI recipe steps, lauter runoff control with Coriolis flowmeter set‑stops, knockout temp/DO logging, and standardized water treatment/mash pH checks.

Results: OG variance tightened to ±0.0015; brewday shortened by ~40 minutes; brewhouse efficiency improved from 84% to 88%; CIP chemical use per batch down ~10%.

Case Study 2: Heat Recovery + Glycol VFDs Reduce Utilities (2024)

Background: 20bbl brewhouse with six 40 bbl FVs struggled with crash times and high water use.

Solution: Added wort‑to‑HLT heat recovery, upgraded insulation on vessels/hot lines, installed VFDs on glycol/hot‑side pumps, and validated CIP endpoints via conductivity.

Results: Water‑to‑beer reduced from 4.2 to 3.4 hL/hL; hot‑side energy/BBL down ~14%; average crash time improved by ~25% with tighter temperature control.

Expert Opinions

- Mary Pellettieri, Quality Consultant; Author of “Quality Management for Breweries”

“Bake QA into daily operations—calibrated probes, DO checks at knockout and transfer, and validated CIP will stabilize quality as throughput scales.” - John Mallett, Brewing & Quality Leader; Author of “Malt: A Practical Guide”

“At 20bbl, lauter management and thermal integration are pivotal. Good milling and controlled runoff protect both efficiency and flavor.” - Laura Ulrich, Senior Brewer and Industry Educator

“Design for oxygen control and cleanability from day one—purgeable fittings, shadowless manways, and smart automation keep hop‑forward beers bright.”

Practical Tools/Resources

- Brewers Association: brewhouse/cellar sizing, sustainability benchmarking: https://www.brewersassociation.org

- ASBC Methods (DO, VDK/diacetyl, pH): https://www.asbcnet.org

- MBAA Technical Quarterly/webinars (CIP validation, low‑DO practices): https://www.mbaa.com

- EHEDG hygienic tank/piping design: https://www.ehedg.org

- DOE AMO calculators (process heating, motors/VFDs): https://www.energy.gov/eere/amo/tools

- Production/QC software for 20bbl operations: https://brewfather.app | https://www.the5thingredient.com/beer30 | https://www.orchestrated.beer

SEO tip: Internally link “20bbl Brewing System” to detailed pages on cellar sizing, heat recovery design, CIP validation, and low‑DO transfers to deepen topical authority and conversion.

Last updated: 2025-09-05

Changelog: Added 5 targeted FAQs, 2025 trend benchmarks with table and sources, two current case studies, expert viewpoints, and practical tools/resources tailored to optimizing a 20bbl Brewing System.

Next review date & triggers: 2026-02-01 or earlier if BA/ASBC/EHEDG guidance updates, DOE benchmarks change, or vendor pricing/lead times shift materially.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?