How To Makes Brewing Easily Via Automation_YoLong Brewtech

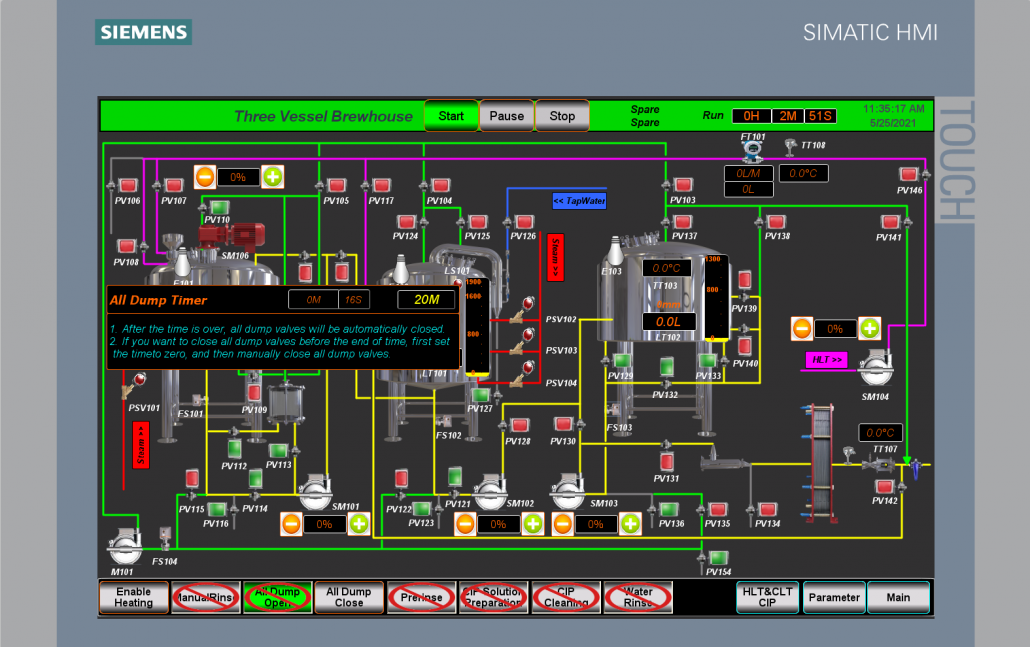

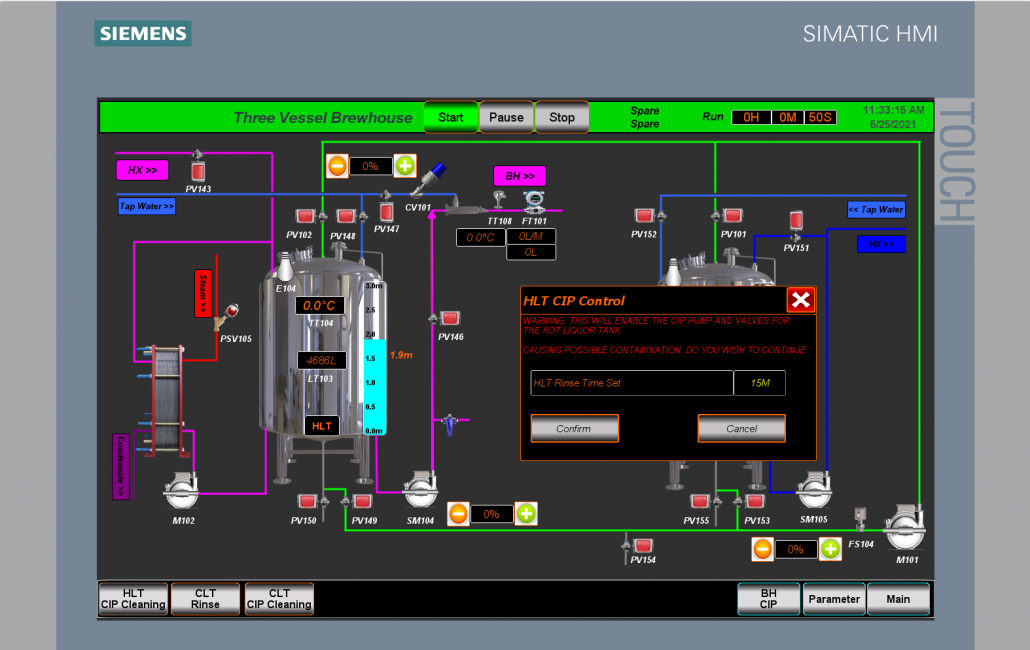

Automation is not just a word, it is a mixture of experience and knowledge and realized by programme and instruments. Instruments and automatic valves are skin and hands & legs, programme is the brain, so it is the most important factor to see a company’s experience.

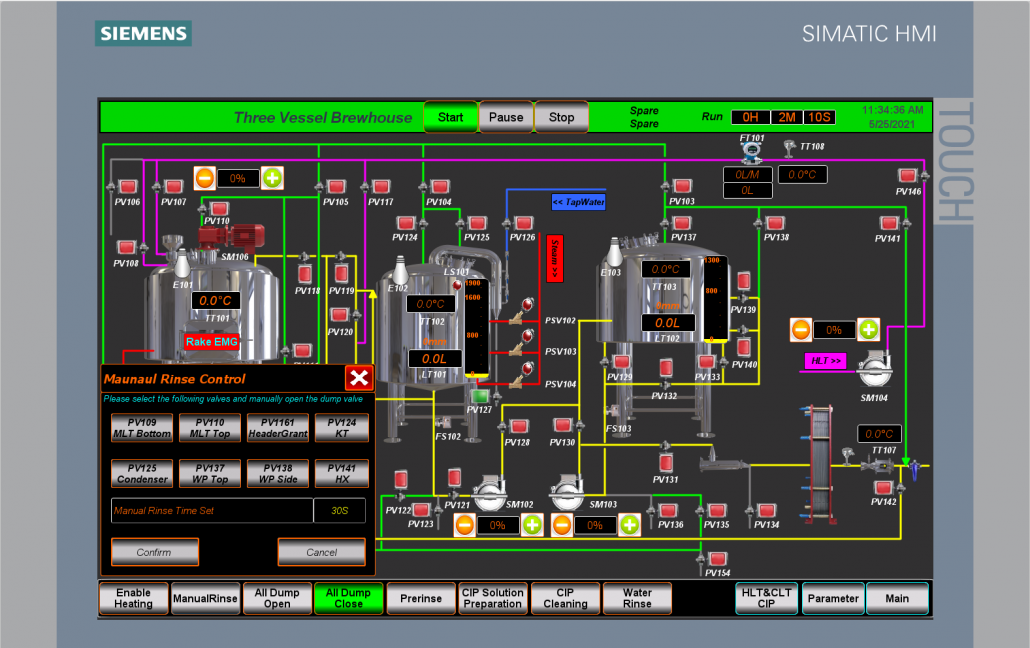

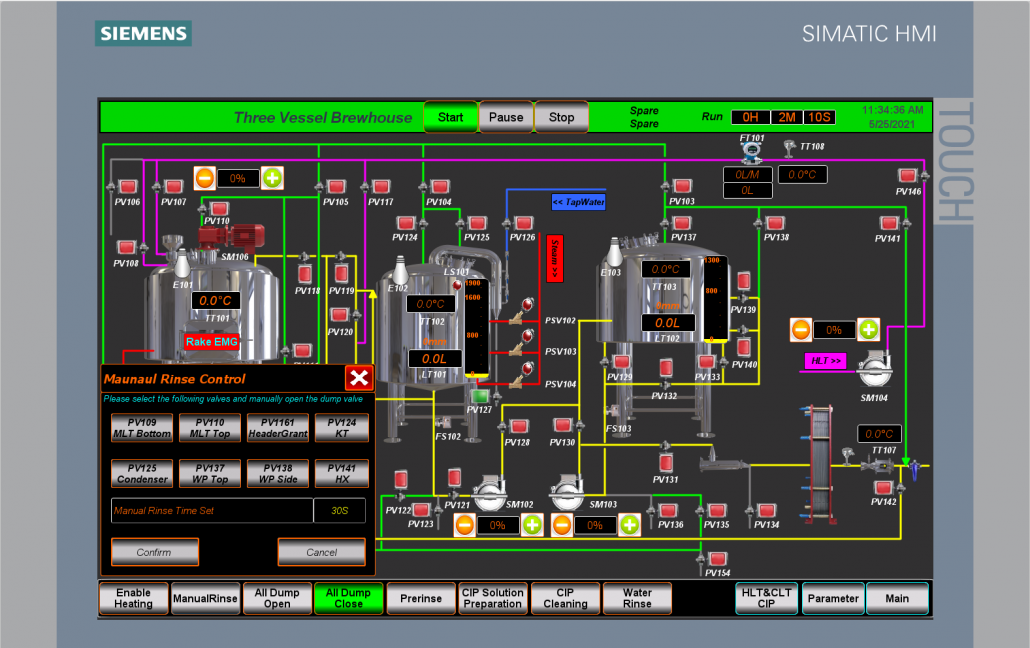

Automation in brewery should connect all parties in brewery in series and monitor & control in control room. Automation saves brewers labour and makes sure people security. Automation helps brewers to think and remind all relative factors which might be ignored or forgotten by person to make sure beer quality. Automation makes sure equipment in normal running condition and avoid broken to have a long working life.

For mid-size craft brewery, investment is one of important issues which has to be considered by owners or investors, so trying to be reasonable automation has been becoming an important research subject for YoLong Programme team. We’ve had lots of “ask for” and “answer” to build communication of each parties.

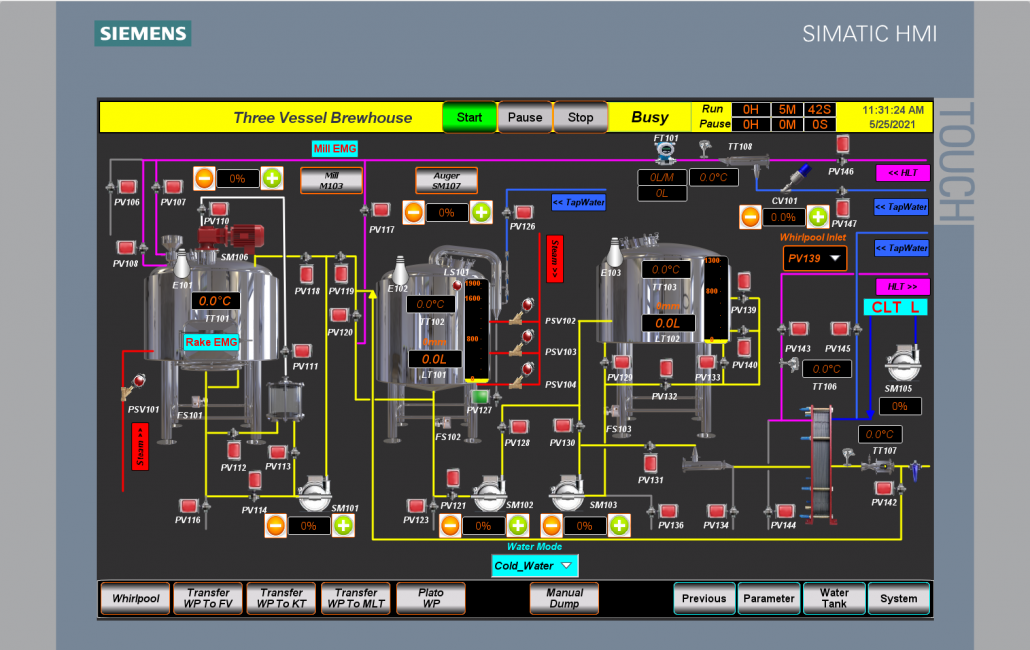

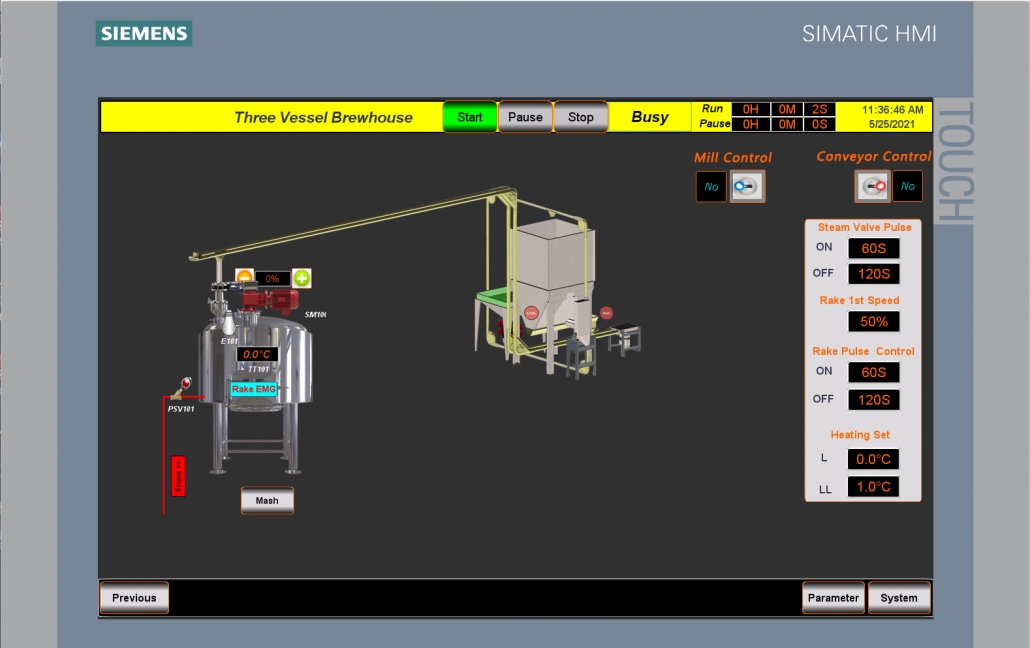

- Prepare malt by BH HMI ( recipe manager for malt mixture, weight controlled grist case), control will be also able via webserver

- Starting brew process briefly description

2.1. pre water insert Mash Tun by user set value (mash in temperature, water value)

2.2. insert mash in water by user set value (mash in temperature, water value) and same time start malt transfer from milling section, start agitator with user speed

2.2. stop malt transfer, rinse grist hydrator (user water value)

2.3. start mashing program, 6 steps. Optional more if needed.

2.4. signal at 72°C rest for iodine check, preparing LT (hot rinse by time or value to heat up, set rakings in low position, lift scraper).

2.5. mash out at 78°C automatically

2.6. mash transfer with pump ramp up to a max. user speed in user given time, start raking at a system given speed to ensure a quite homogeneous leveling of the mash in LT

2.7. at a fixed value (about 75% transferred mash) lift the raking device to top position and stop)

2.8. by evaluated level MT (user given liters left) rinse MT (user water value, fixed 78°C) and transfer to LT

2.9. finish transfer process by flow sensor of mash pump and close LT inlets, start lautering (user given time).

- Starting brew process briefly description

2.1. pre water insert Mash Tun by user set value (mash in temperature, water value)

2.2. insert mash in water by user set value (mash in temperature, water value) and same time start malt transfer from milling section, start agitator with user speed

2.2. stop malt transfer, rinse grist hydrator (user water value)

2.3. start mashing program, 6 steps. Optional more if needed.

2.4. signal at 72°C rest for iodine check, preparing LT (hot rinse by time or value to heat up, set rakings in low position, lift scraper).

2.5. mash out at 78°C automatically

2.6. mash transfer with pump ramp up to a max. user speed in user given time, start raking at a system given speed to ensure a quite homogeneous leveling of the mash in LT

2.7. at a fixed value (about 75% transferred mash) lift the raking device to top position and stop)

2.8. by evaluated level MT (user given liters left) rinse MT (user water value, fixed 78°C) and transfer to LT

2.9. finish transfer process by flow sensor of mash pump and close LT inlets, start lautering (user given time).

4.0. For boiling temperatures,flow and pressure will be watched, automatic hop dosing will be done after user given boiling time.

4.1. when boiling finished user has to confirm gravity and process done.

4.2. transfer to Whirlpool uses similar values as transfer MT-LT. If done Whirlpoolrest(user value).

4.3. Confirmation for cooling start.

4.4. Automatic wort cooling, by flow and temperature.

Additional FAQs on Brewing Easily Via Automation

- Q: Which brewhouse processes benefit most from automation first?

A: Mash temperature steps, lauter rake control/ΔP monitoring, boil-off control, whirlpool timing, and wort cooling. These reduce variance, shorten cycle time, and prevent operator error. - Q: How does an HMI/recipe manager improve consistency?

A: It stores mash/boil step profiles, water volumes, pump/VFD speeds, and hop dosing times. Operators select a recipe, and the PLC executes repeatable sequences with interlocks and alarms. - Q: What sensors are critical to make brewing easily via automation reliable?

A: RTD temperature probes, level transmitters, flow switches/meters, pressure switches for pneumatics, conductivity for CIP endpoints, and DO probes at knockout. Together they enable safe interlocks and quality control. - Q: Can automation scale from a 2-vessel to a 3–4 vessel brewhouse?

A: Yes. Start with semi-automation (PID temp, pump/valve interlocks, recipe steps), then add modules like automatic hop dosing, lauter ΔP control, and CIP sequencing as throughput grows. - Q: What cybersecurity basics apply to a brewery control network?

A: Isolate PLC/HMI from guest Wi‑Fi, use strong credentials/VPN for remote support, maintain firmware updates, and log changes. Network segmentation protects alarms/notifications from unauthorized access.

2025 Industry Trends in Automated Brewing

- Modular automation: IO‑Link/plug‑and‑play devices reduce commissioning to days and enable quick swap diagnostics.

- Data-first operations: electronic batch records (EBR), CIP logs, and alarm histories are standard for audits and insurance.

- Energy and water optimization: heat recovery, VFDs, and sensor-driven CIP endpoints commonly cut utilities 10–25%.

- Closed-process controls: automated purge/pressure routines minimize oxygen pickup in transfers and hop dosing.

- Remote visibility: secure webserver HMIs and mobile alerts support lean staffing without sacrificing control.

2025 Automation Benchmarks and ROI Signals

| Metric/Practice | Typical Target/Range | Impact |

|---|---|---|

| Mash temp control accuracy | ±0.2–0.5°C | Predictable enzyme activity and attenuation |

| Boil-off control variance | ≤±0.3%/h | Stable gravity and bitterness |

| Lauter differential pressure control | 0.2–0.6 bar window | Faster runoff, reduced stuck mash risk |

| Knockout DO (with closed transfer) | <0.10–0.30 ppm | Better flavor stability |

| CIP endpoints (conductivity/time) | Automated with verification | 10–20% utility savings |

| OEE improvement after automation | +5–15% | Higher throughput, fewer rebrews |

| Commissioning timeline (FAT-tested skid) | 3–10 days | Faster time-to-first-wort |

Sources: Brewers Association Quality/Sustainability benchmarking, MBAA Technical Quarterly, OEM application notes (2024–2025). Validate locally with utilities and site conditions.

Latest Research Cases

Case Study 1: Recipe Automation Cut Variability and Labor (2025)

- Background: A 20 hL 3-vessel brewhouse had batch-to-batch gravity and IBU drift, with frequent manual interventions.

- Solution: Implemented PLC/HMI recipe manager with automated mash steps, boil-off control, and timed hop dosing; added flow switches for interlocks and webserver-based confirmations.

- Results: OG variance reduced 35%; IBU variance down 22%; average brew day shortened by 48 minutes; operator labor reduced ~0.6 FTE equivalent.

Case Study 2: Sensor-Driven CIP Reduced Utilities and Downtime (2024)

- Background: Excessive CIP time and chemical spend with inconsistent cleaning outcomes.

- Solution: Added conductivity-based caustic/rinse endpoints, flow/pressure verification across spray devices, and automated log capture in HMI.

- Results: Water per CIP down 18%; caustic use down 20%; CIP cycle time reduced by 12–15 minutes; zero CIP-related quality holds over 6 months.

Sources: Brewers Association Quality and Sustainability tools; MBAA TQ case notes on automation, oxygen control, and CIP validation; vendor guides on IO‑Link and EBR. Outcomes vary with SOP adherence and facility constraints.

Expert Opinions

- Mary Pellettieri, Brewing Quality Consultant; Author, “Quality Management for Breweries”

- Viewpoint: “Automate what protects flavor first—temperature, oxygen control, and cleaning verification—then add convenience features.”

- Reference: Brewers Association Quality resources (https://www.brewersassociation.org/)

- John Mallett, Former VP Operations, Bell’s Brewery; Author of “Malt”

- Viewpoint: “Reliable instrumentation, weld quality, and jacket zoning are the foundation—automation amplifies, it doesn’t replace fundamentals.”

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

- Viewpoint: “Tight thermal histories and controlled oxygen exposure from brewhouse through knockout drive hop expression and shelf life.”

Practical Tools and Resources

- Brewers Association: Quality, Safety, Sustainability, benchmarking — https://www.brewersassociation.org/

- Master Brewers Association of the Americas (MBAA) Technical Quarterly — https://www.mbaa.com/

- ISA/IEC standards for controls and instrumentation — https://www.isa.org/

- PLC/HMI platforms and guides: Rockwell Automation — https://www.rockwellautomation.com/; Siemens — https://new.siemens.com/

- Sensor OEMs (IO‑Link, sanitary): IFM — https://www.ifm.com/; Endress+Hauser — https://www.endress.com/; Bürkert — https://www.burkert.com/

- Sanitation chemistry and validation: Five Star Chemicals — https://fivestarchemicals.com/

Last updated: 2025-09-04

Changelog: Added 5 focused FAQs on automation essentials; included 2025 automation benchmarks table and trends; provided two case studies on recipe automation and sensor-driven CIP; added expert viewpoints; curated tools/resources with authoritative links.

Next review date & triggers: 2026-03-01 or earlier if BA/MBAA release updated automation/CIP guidance, ISA/IEC control standards change, or OEMs introduce new modular automation impacting commissioning timelines and ROI.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?