How to Design your Brewery Layout?

Brewery layout is very important when you decide to open a brewery, you will embark on a long and stressful journey. This journey will help you determine the best brewery floor plan for you, and of course, you may gain more information. Opening a brewery is not all a game, you need to plan, design and finally build the brewery.

So, How to Design your Brewery Layout?We can pay attention to the following points;

Preparations for setup the brewery

What should be paid attention to when designing a brewery floor plan?

Factors to consider in a brewery floor plan

Cost savings

1. Preparations For Set up The Brewery

If you’re passionate about brewing and want to turn it into a business, setting up a brewery might be the perfect way to turn your hobby into a profitable venture. However, before you start experimenting with design, there are a lot of things you need to consider.

Understanding the Industry

Before diving into the process of setting up a brewery, it’s essential to understand the industry. You should start by talking to different breweries, friends, brewers, forums, and blogs to get a sense of what it takes to start a brewery successfully. You can learn from their experiences and mistakes, which can help you avoid costly errors in the future.

It’s also a good idea to research the market demand for your product. What are the trends in craft beer, and how can you position your product to stand out in a crowded market? Understanding the industry’s ins and outs will help you develop a viable business plan and set realistic goals.

Building Your Team

Once you’ve done your research, it’s time to start building your team. You’ll need a group of people with different skills and expertise to make your brewery a success. Some of the people you’ll need to consider include: Brewers, Sales and marketing personnel, Administration and accounting personnel,Taproom and hospitality personnel.

You may need to hire contractors with experience in building breweries. The construction of a brewery is the same as other construction projects; there will always be unforeseen costs. Therefore, you need to make sure that you have sufficient funds and a good working time frame to complete your project.

Financing Your Brewery

The next step is to finance your brewery. Starting a brewery can be expensive, so it’s essential to plan your financing carefully. Some of the funding options available to you include: Crowdfunding, Angel investors, Bank loans and Small Business Administration (SBA) loans.

It’s essential to have a solid business plan that outlines your projected revenue, expenses, and profit margins. This plan will help you secure funding and make informed decisions throughout the process.

Choosing Your Brewery’s Location

The location of your brewery is crucial to its success. You need to consider several factors, including:

- The size of your brewery

- Zoning and building codes

- Availability of utilities such as water, gas, and electricity

- Access to transportation and distribution networks

- Potential competition in the area

Once you’ve narrowed down your options, you’ll need to evaluate each location’s pros and cons to determine the best choice for your brewery.

Marketing and Branding

Once you’ve set up your brewery, you’ll need to develop a marketing and branding strategy to promote your product and attract customers. You can start by creating a brand identity that reflects your brewery’s personality and values. This includes designing a logo, creating a website, and developing a social media presence.

You can also consider hosting events such as tastings, tours, and collaborations with local businesses to promote your brewery and build a loyal customer base. Networking with other breweries and industry professionals can also help you establish your brand and reach a wider audience.

2.What Should Be Paid Attention To When Designing A Brewery Floor Plan?

A well-designed brewery floor plan is crucial for the safety, efficiency, and profitability of a brewery. A poorly designed layout can lead to safety hazards, bottlenecks in production, and a poor customer experience. In this article, we will discuss some of the key factors to consider when designing a brewery floor plan.

Designing a brewery floor plan

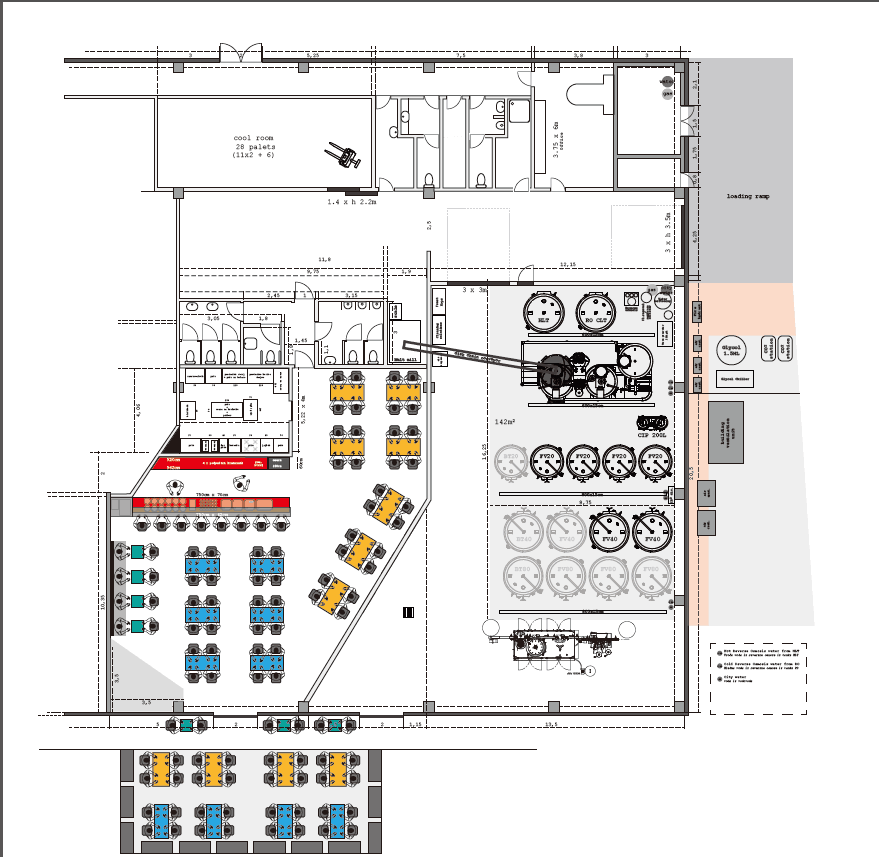

Starting with the raw materials area

The raw materials area is the starting point for the brewing process and should be given careful consideration when designing a brewery floor plan. The area should be located close to the loading dock or other areas where materials are received to ensure efficient material handling. The materials should be stored in a dry, temperature-controlled area to prevent spoilage and maintain quality.

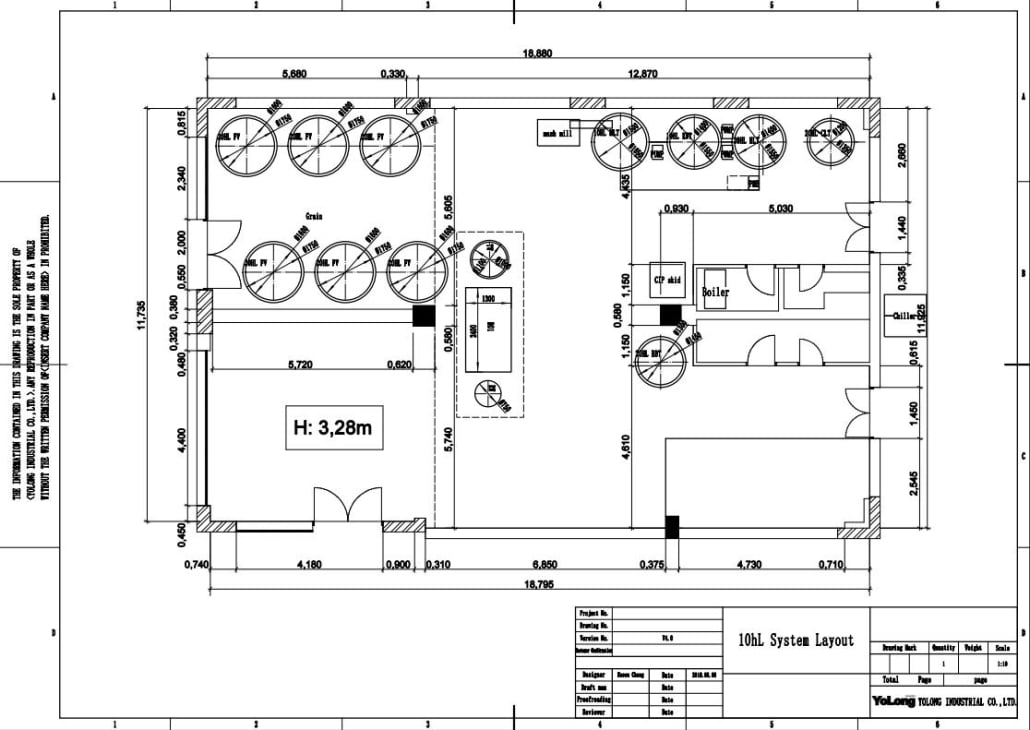

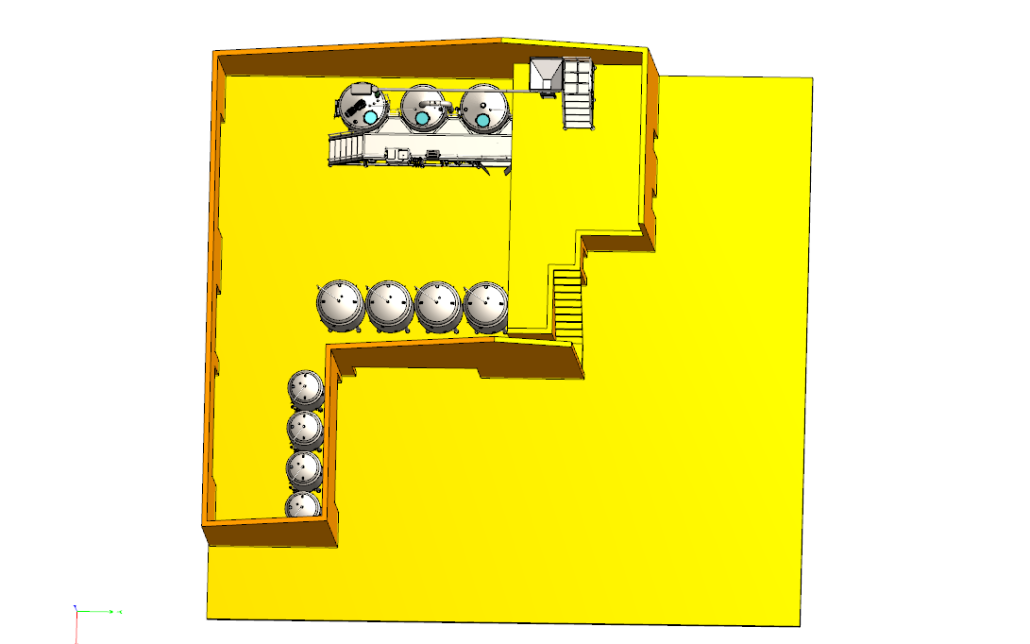

Equipment placement and spacing

Equipment placement and spacing are critical for the efficient operation of a brewery. The placement of equipment should be carefully planned to allow for easy access and maintenance. The spacing between equipment should be sufficient to allow for safe operation and maintenance, but not so much that it creates unnecessary travel for personnel.

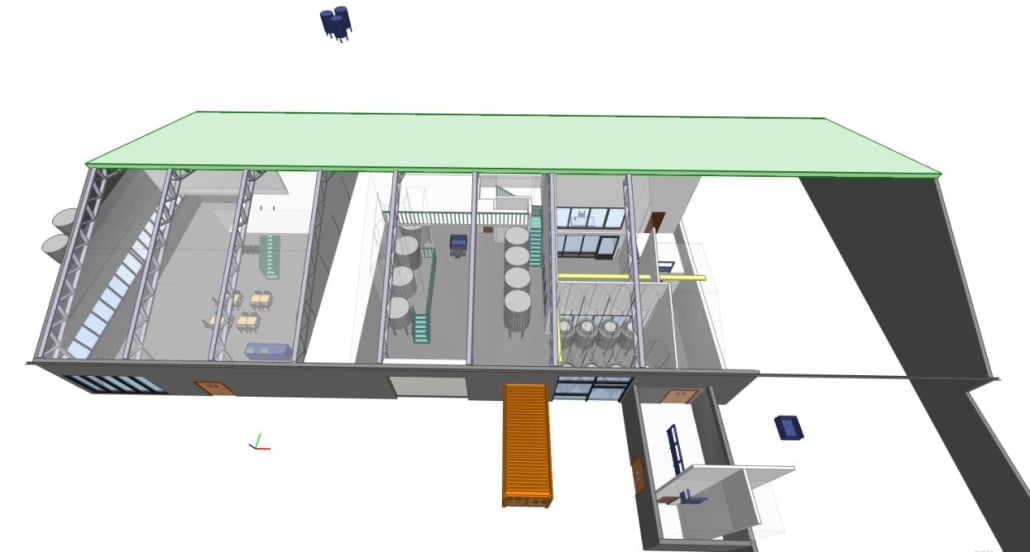

Flow of materials and personnel

The flow of materials and personnel should be carefully planned to ensure that the brewing process is efficient and safe. The flow should be designed to prevent bottlenecks and minimize the risk of accidents. It should be easy for personnel to move between different areas of the brewery without interfering with the production process.

Taproom design considerations

The taproom is an essential part of the brewery experience, and its design should be considered when designing the brewery floor plan. The taproom should be located in a separate area from the production area to prevent customers from interfering with the production process. The design should allow for efficient service and easy flow of customers.

Safety considerations

Safety should be a top priority when designing a brewery floor plan. The following are some of the safety considerations to keep in mind:

Material storage

Materials should be stored in a safe and secure manner to prevent accidents and injuries. Hazardous materials should be stored in designated areas and labeled appropriately. The storage area should be well-ventilated and free from sources of ignition.

Electrical and plumbing safety

Electrical and plumbing systems should be designed and installed by qualified professionals to ensure safety and compliance with local regulations. All electrical equipment should be properly grounded, and plumbing systems should be designed to prevent leaks and contamination.

Fire safety

Fire safety is a critical consideration in any brewery. The design should include fire suppression systems, such as sprinklers or fire extinguishers, and a well-planned evacuation plan.

Regulations and permits

Compliance with local regulations and permitting requirements is essential when designing a brewery floor plan. The design should be reviewed by a qualified professional to ensure compliance with local building codes and regulations. Permits may be required for construction, plumbing, electrical, and fire safety.

In conclusion, a well-designed brewery floor plan is essential for the safety, efficiency, and profitability of a brewery. Designing a brewery floor plan involves careful consideration of the raw materials area, equipment placement and spacing, flow of materials and personnel, taproom design considerations, safety considerations, and compliance with

3.Factors To Consider In A Brewery Floor Plan

Breweries are unique production facilities that require specialized floor plans to operate effectively. To ensure the success of your brewery, it is important to carefully consider the layout of your facility. This section will provide guidance on the factors to consider in a brewery floor plan.

Water Supply

Water is a critical component of the brewing process, and a reliable water supply is essential for any brewery. When designing your brewery floor plan, consider the location of your water supply and the routing of your plumbing. You should also consider the water quality and make sure that it meets the requirements of your brewing process.

Electricity Supply

Electricity is another critical component of the brewing process, and it is important to ensure that your brewery has a reliable and robust electrical supply. You should consider the location of your electrical panels and the routing of your electrical wiring to ensure that your equipment has the power it needs to operate effectively.

Grain Bucket

The grain bucket is an essential component of the brewing process, and it is important to ensure that it is located in a convenient location within your brewery. You should consider the size of your grain bucket and make sure that it can accommodate the amount of grain you will need for your brewing operation.

Packaging and Labeling Area

The packaging and labeling area is where your beer is packaged and labeled for distribution. When designing your brewery floor plan, consider the location of your packaging and labeling area and the routing of your beer lines. You should also consider the size of your packaging and labeling area and make sure that it can accommodate your production volume.

Drainage System

The drainage system is a critical component of any brewery floor plan. You should consider the slope of your floor and make sure that your drainage system is designed to operate effectively at that slope. You should also consider the location of your drains and make sure that they are easily accessible for cleaning and maintenance.

In Conclusion, Designing a brewery floor plan requires careful consideration of a variety of factors, including water supply, electricity supply, grain bucket, packaging and labeling area, and drainage system. By taking these factors into account, you can design a floor plan that will improve efficiency, reduce waste, and improve safety in your brewing operation.

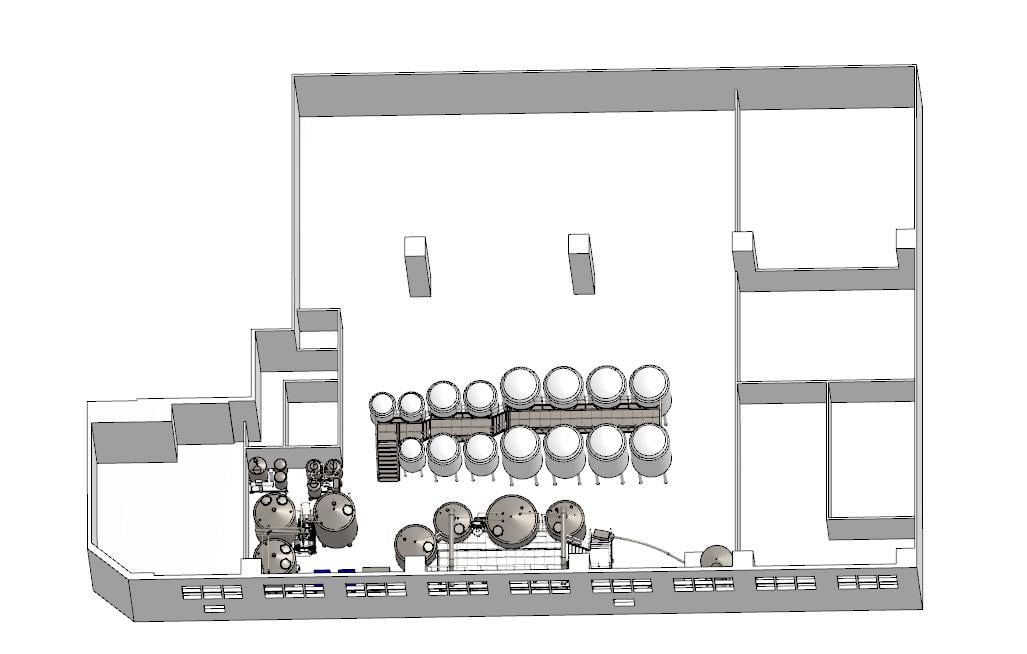

When you have to build your brewery, it’s important to plan ahead. This includes preparing the site to ensure that the equipment can be positioned and moved during the installation process. Everything from forklifts and pallet trucks are used during the storage of raw materials, to a door for each area so that products in packaging can move freely. If your brewery does not match these activities, you may need to re-plan it. You can find layouts and designs of some successful breweries here;

Brewery setup depends on the type of equipment and the size of the brewery. To reduce energy costs and improve efficiency, place brewing equipment as close together as possible. Reducing the distance between different steps reduces the amount of pumping required and helps prevent unexpected tastes in beer quality. Find out about “How do I set up a brewery?” here;

Before opening a craft brewery, you need to consider many factors, such as brewing technology and brewery equipment costs. Once you find a location for your brewery that meets code requirements and is zoned appropriately, you may need to apply for a permit from your local government department. References you use, e.g. Beer – TTBGov, USA. Or you can get more brewery friends on BA to chat by your side.

However, for us, YoLong can consider some issues from a design/manufacturer’s point of view; YoLong is happy to help you with questions about the layout of your brewery design when you choose to work with us. We can provide useful suggestions from our experience in helping brewers open up their own breweries. You can leave your brewery plans here;

4.Cost Savings

Brewing beer is a craft that requires skill and expertise, but it’s also a business. When opening a brewery, it’s important to consider the financial aspect of the operation. One way to reduce costs over time is to design an energy-efficient brewery.

The Benefits of a Well-Planned Brewery Design

The benefit of a well-planned brewery design is a cumulative effect that will reduce costs over time. A well-designed brewing facility will be more energy efficient, which will lower your long-term cost of brewing. Here are some ways a well-planned brewery design can help you save costs:

Energy Efficiency

A well-designed brewery will be more energy efficient. During the brewing process, a lot of energy is needed to heat water and run equipment. By designing an energy-efficient brewery, you can reduce your energy usage and save money on utility bills.

Increased Productivity

A well-designed brewery can also increase productivity. By optimizing the layout of your brewery, you can reduce the time it takes to move ingredients and equipment around. This can increase your production capacity and help you meet demand.

Improved Quality Control

Quality control is an important aspect of brewing. By designing a brewery with quality control in mind, you can reduce the risk of contamination and ensure that your beer is of the highest quality. This can help you avoid costly recalls and reputational damage.

Measures to Reduce Costs

When designing your brewery, there are measures you can take to reduce costs. Here are some ways to save money when setting up your brewery:

Equipment

Investing in quality equipment can save you money in the long run. High-quality equipment is less likely to break down, which can save you money on repairs and replacements. Additionally, energy-efficient equipment can reduce your energy bills.

Location

Choosing the right location for your brewery can also save you money. Look for a location that is affordable and has easy access to transportation. Additionally, consider the local tax laws and regulations to ensure you’re not paying more than necessary.

Production Process

Optimizing your production process can also reduce costs. By reducing waste and optimizing your workflow, you can save money on ingredients and labor. Additionally, consider using locally sourced ingredients to save on transportation costs.

Frequently Asked Questions (FAQ)

1) How much space do I need for an efficient Brewery Layout?

- As a rule of thumb, plan 1.5–2.5 sq ft per annual bbl of production for back-of-house, plus taproom/storage. A 7–10 bbl brewhouse with four fermenters typically needs 2,500–4,000 sq ft including cold box and circulation.

2) What is the ideal process flow in a Brewery Layout?

- Linear or U-shaped flow: receiving/storage → milling → brewhouse → fermentation/cellaring → packaging → cold storage → shipping. Minimize cross-traffic between raw and finished goods.

3) Where should I place the cold room in the layout?

- Adjacent to packaging and near the loading dock to shorten warm-time exposure. Keep a short, insulated route from bright tanks to filler/serving tanks to reduce DO pickup and line losses.

4) How do I size utilities for the layout phase?

- Early-load calculations: electrical (brewhouse kW, pumps, compressors), glycol (1.2–1.5 ton per 10 bbl fermentation load, with diversity factor), steam (1.2–1.5× boil load), and floor drainage (1–2% slope; 4–6 in trench with baskets).

5) What are common layout mistakes to avoid?

- Undersized drains, tight door clearances for tank installs, no forklift turning radius, long hose runs, poor ventilation over brewhouse, and inadequate chemical storage/eyewash placement.

2025 Industry Trends: Brewery Layout and Facility Design

- Smart cellar integration: sensors (temp/pressure/level) feeding PLC/SCADA for predictive VDK rests and automated crash/transfer scheduling.

- Energy-first design: brewhouse heat recovery, insulated glycol headers, and demand-controlled ventilation lower energy intensity 10–20%.

- Draft quality by design: shorter, insulated beer runs, on-site nitrogen generation, and DO monitoring stations embedded in packaging lines.

- Safety and compliance: more jurisdictions mandating fixed CO2 monitors, LEL sensors near grain handling, and documented PRV testing zones.

- Flexible footprints: modular tanks, quick-disconnect manifolds, and movable canning lines allow seasonal reconfiguration without re-permitting.

2025 Planning Benchmarks for Brewery Layouts

| Planning Item | Nano (1–3 bbl) | Small Craft (5–10 bbl) | Production (15–30 bbl) | Notes/Sources |

|---|---|---|---|---|

| Back-of-house area | 600–1,200 sq ft | 1,800–3,000 sq ft | 4,000–8,000 sq ft | Brewers Association facility guides |

| Floor slope & drains | 1–2% to trench; 4–6 in trench width | Same | Same, add zone isolation | MBAA best practices |

| Ceiling height clear | 12–14 ft | 16–20 ft | 20–28 ft | Allow tank lifts and CIP clearance |

| Glycol tonnage (peak) | ~0.3–0.6 ton | ~1.0–2.0 ton | ~3–6 ton | Diversity factor by concurrent crashes |

| Electrical service | 100–200 A, 3φ optional | 200–600 A, 3φ | 600–1,200+ A, 3φ | Heat source dependent |

| Cold room size | 80–180 sq ft | 180–450 sq ft | 450–1,000+ sq ft | Based on SKUs and draft strategy |

| People flow | Shared BOH/taproom access | Separated with viewing | Fully separated with corridors | GMP and safety |

References:

- Brewers Association: https://www.brewersassociation.org

- Master Brewers Association of the Americas (MBAA): https://www.mbaa.com

- OSHA ventilation and hazard controls: https://www.osha.gov

Latest Research Cases

Case Study 1: U-Flow Layout Cuts Hose Runs and DO Pickup (2025)

Background: A 10 bbl taproom brewery had long, crisscrossed paths between bright tanks and the canning line, causing higher dissolved oxygen and labor drag.

Solution: Reoriented to a U-shaped Brewery Layout with bright tanks adjacent to packaging, added insulated, hard-piped transfer lines, and installed a small DO meter checkpoint.

Results: Transfer time reduced 28%; packaged DO median fell from 110 ppb to 45 ppb; weekly packaging labor hours dropped 12%.

Case Study 2: Energy-First Retrofit with Heat Recovery (2024)

Background: A 15 bbl facility struggled with rising utilities and hot, humid brewhouse conditions.

Solution: Installed wort-to-water heat recovery, insulated glycol mains, demand-controlled make-up air, and added CO2 monitoring with alarm zoning.

Results: 19% energy/bbl reduction; brewhouse WB temperature lowered by 4–6°C on double-brew days; fewer nuisance CO2 alarms.

Expert Opinions

- Scott Jennings, Brewing Innovation, Sierra Nevada Brewing Co.

Key viewpoint: “Design-in cleanability and safety. Short, hard-piped runs, proper drainage, and service clearances pay back in uptime and quality.” - Ashton Lewis, Brewing Scientist and MBAA contributor

Key viewpoint: “Think in flows—materials, people, air, and wastewater. Avoid backtracking and keep raw and finished goods separated in the Brewery Layout.” - Katie Wallace, Sustainability leader in craft brewing

Key viewpoint: “Insulation, heat recovery, and right-sized glycol are layout choices as much as equipment choices. They’re your fastest route to lower operating costs.”

Practical Tools/Resources

- Brewers Association layout and safety checklists

https://www.brewersassociation.org - MBAA Technical Quarterly on drainage, CIP coverage, and cellar design

https://www.mbaa.com - ASHRAE/OSHA guidance for ventilation and indoor air quality

https://www.ashrae.org | https://www.osha.gov - DSIRE database for energy incentives (US)

https://www.dsireusa.org - Packaging line DO/oxygen measurement methods (ASBC)

https://www.asbcnet.org

SEO note: Internally link to “Brewery Layout,” “brewhouse heat recovery,” “glycol system sizing,” “packaging DO control,” and “brewery drainage design.”

Last updated: 2025-08-28

Changelog: Added 5 FAQs; 2025 layout trends with planning benchmarks table; two concise case studies; expert viewpoints; and practical design/resources aligned to Brewery Layout planning

Next review date & triggers: 2026-02-01 or earlier if BA/MBAA release new facility benchmarks, local codes change for CO2/ventilation, or energy incentive programs are updated

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?