GLYCOL WATER TANK (GWT)& COLD WATER TANK(CWT)

What exactly is the difference between the Glycol Water Tank (GWT)& Cold Water Tank (CWT)? How do we make choices as a brewer?

Cold liquor tanks. Cold water does not contain alcohol. This means that the temperature of the liquid in the tank is maintained above freezing. Set the temperature according to the brewing process requirements. The main sources of these water are tap water, ro water, etc. that can be used for brewing.

Glycol water tank.The biggest difference between the GWT and the CWT is the liquid inside. The main component is a mixture of tap water and ethanol or propylene glycol, which is expensive. The function of alcohols is to lower the freezing point, so that the working temperature of the glycol is generally maintained at about minus three degrees to minus five degrees.It cannot be in direct contact with wort, and cannot be used for brewing. It can only be circulated in the glycol tank and pipeline.

Both can be used as cooling tanks, during design the brewery, you could decide whether to use it or not after full consideration according to the project budget, room space and brewing process design.

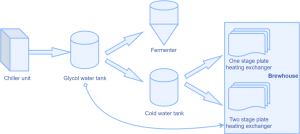

- The chiller unit cools the liquid in the glycol tank.

- The glycol tank is use to cool the fermentation tank and the cold water tank.

- The liquid in the cold water tank is mainly used to cool down the beer wort. After go through the plate heat exchanger which located at brewhouse, the cold water is heated to more than 80 degrees by hot wort. The heated water will recycle into the hot water tank for the next batch of brewing work or other cleaning work.

- If only use cold water to cool the wort is not enough, the glycol tank can also be used for secondary cooling.

In order to avoid the burden on the cooling system due to excessive heat exchange power in the process of cooling the wort at the plate heat exchanger, which will affect the fermentation temperature control, CWT can be used as a buffer tank to receive the heat and keep the glycol tank running at lower temperature.

To sum up

- The rational use of CWT can save water and energy consumption, reduce hot water preparation time, increase brewing batches, and ensure that the cooling of the fermentation process is not affected. Commonly found in brewing systems above 10hlor brewing several batches per day.

- For smaller breweries orbrewpub We can eliminate the cold water tank and only use the glycol tank to cool both the plate heating exchanger in brewhouse and the fermentation tank. When cooling the hot boiled wort, it will cause the glycol water to heat up rapidly. But if you have budget and space limit.Or you only to brew one batch of beer in one day. You can just use glycol tank do all the cooling work. Therefore, it is usually find in brewpub or restaurant.

ARE YOU HAVE BREWING QUESTIONS?

WE CAN HELP!

YoLong Brewtech has been engaged in consulting, design and manufacture of professional beer brewing equipment since 2004. And are actively sharing our expertise on more brewing and equipment. If you have any questions or requirements about brewing equipment, you can contact our professional technical engineers to find the answer.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!