YoLong Automated Brewery Control Systems

There is a distinct correlation between the quality of beer and the system that is setup to replicate it precisely for every batch.

A YoLong control system is the key to guaranteed consistent beer quality. It’s as simple as that. Of course, the brewmaster’s expertise and overseeing plays an important role in brewery functionality, but a YoLong control system can monitor and standardize according to the necessary configuration requirements and beer characteristics.

The reason why our automated control systems are considered to be the best in the world is because of two important factors:

- YoLong’s dedicated professional electronic design and compilation team

- YoLong’s cost-effective in-house integration of brewery equipment and automation

This unbeatable combination produces individual control systems based around Siemens, AB, and Omron technologies with certification of CE/UL/ CUL certification standards.

YoLong Brewhouse Control Panel

Semi-Automatic Control System (Temperature Controller)

The YoLong semi-automatic control system can be found in microbreweries, nano breweries, farm and cottage industry breweries, and brewpubs all over the world. This is because a semi-automatic control system is ideally suited for small-scale, small capacity brewery output.

The YoLong semi-automatic control system design team have over 15 years’ experience in compiling automated systems that improve small-scale brewery functionality. By automating certain stages of the brewing process, it relieves the necessity to oversee every production stage or hire extra staff.

The semi-automatic control system integrates with brewhouse and cellar tanks’ manual operating material flow and temperature setting. The semi-automatic control system, as part of a new small-scale brewery setup, accounts for around 10 – 15% of the total cost. However, a control system saves the brewery from additional expenses once production begins – far beyond those of your initial spend.

Brewhouse temp controller cabinet

Brewhouse cabinet function:

- Temperature displayof hot water inlet, mixed water, and cooled wort

- Flow measure for mixed water.

- Temperature display and auto/manual control for MLT & KWP

- VFD control for wort pumps and rake

- Emergency Stop & Alarm

Cellar temp controller cabinet

Cellar cabinet function:

- Temperature display & auto control for cellar tanks

- Level display for brite beer tanks (Optional)

- Glycol tank temperature display & auto control

- Glycol Pump OFF/Manual/Auto

- Chiller Working Status

Automatic Control System (PLC) For Small Amount Microbrewery

With the rapid development of microbrewery programs, more owners are choosing to automate their breweries. The fully automatic control system YoLong offers has advanced features and programming created for optimal productivity and minimal manual labor. This is only one of the factors that influences brewery owners to install a fully automatic control system:

- Labor saving

- Easy to monitor

- Simple, smart operation

- Settings memory

- Consistent beer quality guarantee

What about the cost of an Automatic Control System? This is a valid concern, as everything installed into a brewery or brewery expansion must be viable and cost-effective to warrant the initial expense (approximately 17 – 25% of complete brewery setup costs). In the short term and long term cost saving projections, installing a fully automated control system in a brewery leads to improved efficiency creating long-term cost savings.

For short term cost projections, at the start of production a fully automated system immediately saves on utility expenditure (by monitoring energy) and labor costs. Automation in a brewery also frees up the owner’s time so they can concentrate of other important aspects of the business: marketing, promotion, and advertising.

YoLong offers a competitive program to enable you, the brewer, to save on labor, utilities, and production costs while still maintaining complete brew control from a human perspective.

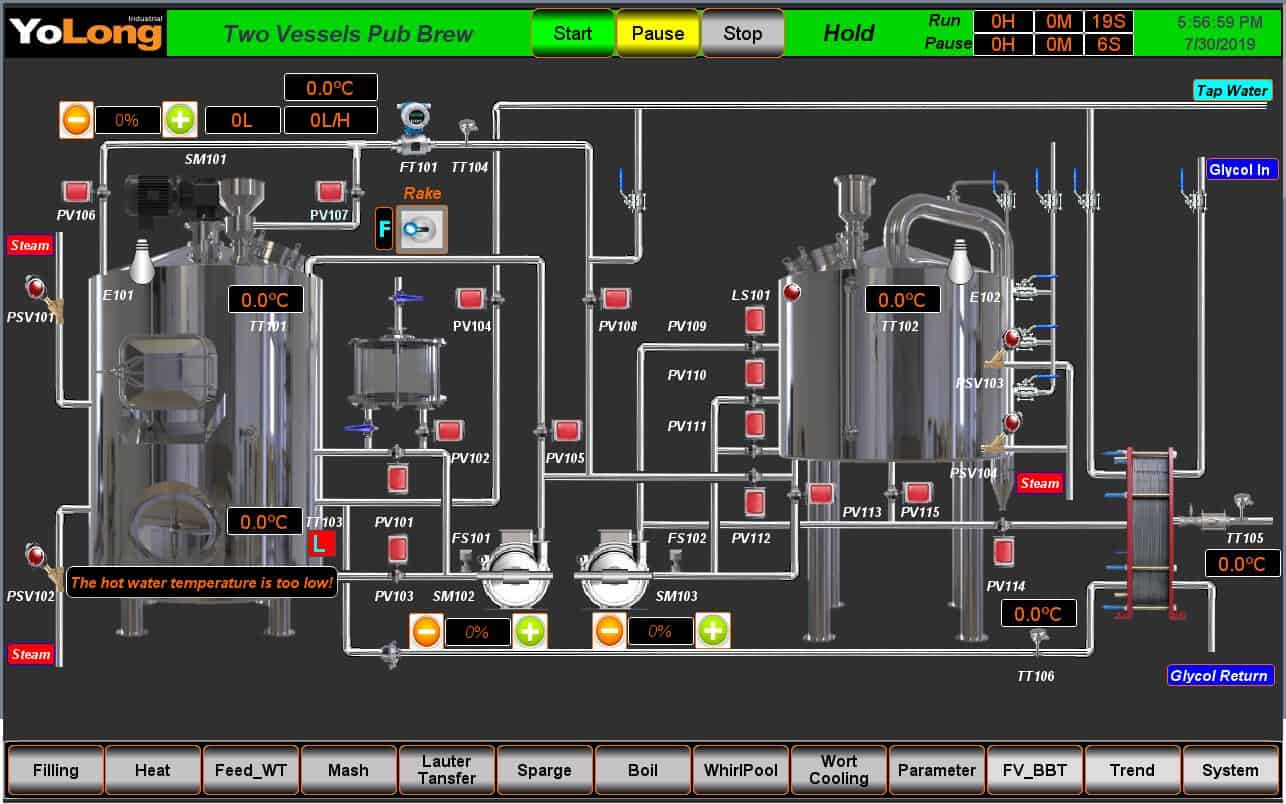

PLC Brewhouse Panel

Brewhouse cabinet function:

- All temperature digital display & auto control

- Water mixing station for setting temperature and measuring filling volume for MLT water filling & sparge water filling

- Tank lights ON/OFF

- Pumps anti-slip protection

- VFD control for all pumps (variable speed drive)

- Material auto flow

- Motor for rake ON/OFF & VFD control for rake speed

- Kettle Anti-Foam (Overflow) protection

- Alarm buzzer function

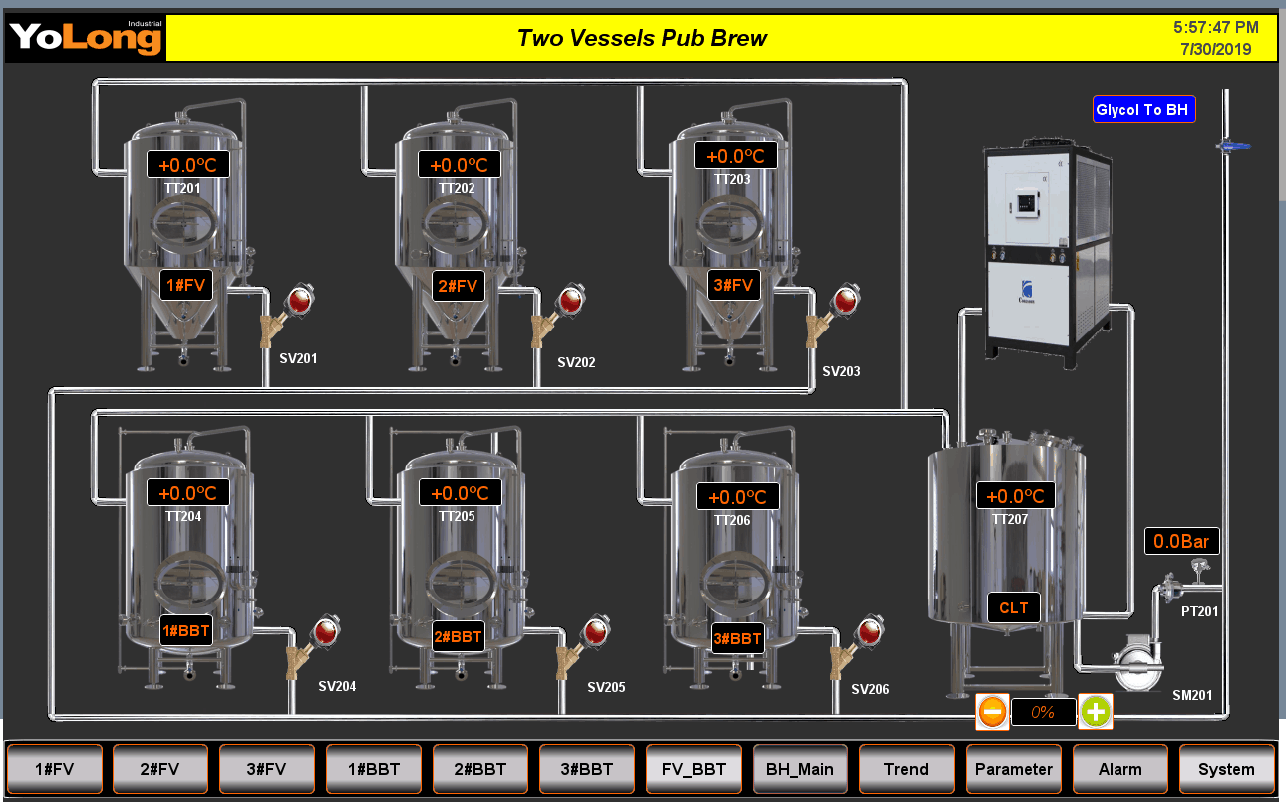

PLC Cellar Panel

Cellar cabinet function:

- Digital display temperature in cellar tanks

- Temperature auto control in CLT

- Five stage temperature auto control in fermenters (Five stage for temperature rise & keeping for different beer)

- Temperature auto control in BBTs

- Alarm buzzer function

Fully Automatic Control System (PLC) For Large Amount Microbrewery

YoLong offers everything you need for the automation, monitoring, and control of your entire large-scale brewery.

Advantages:

- Reduction in labor

- Improved beer quality and consistency

- Automatic brewhouse temperature, material flow, receipt control, and temperature control of your cellar tanks (fermentation tank, brite beer tank, etc)

- Energy Recovery

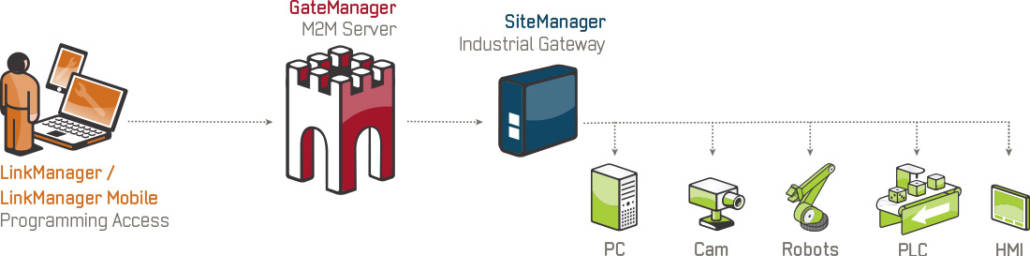

- System configuration for a link to ethernet

- Automatic access to production and equipment communication

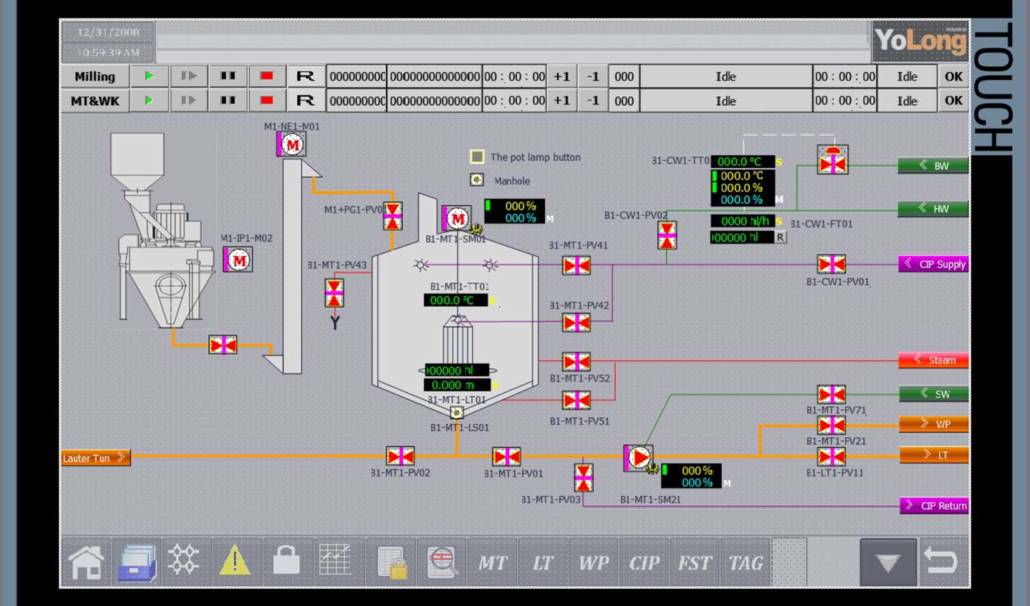

1. TC Control System

YoLong have been perfecting brewery and beverage automation for over 10 years. Our programming team has streamlined automatic control systems for efficiency and easy operation. Over the last ten years, we have built up an excellent relationship with the Rockwell & Siemens systems operation division.

YoLong can offer CE, UL, and CUL certified control cabinets with electronic elements suitable for customers all over the world. With our TC Control Systems, you will be able to see the required process at glance and integrate it into your production seamlessly.

TC Control means Touchscreen Controls. The brewery system is mainly controlled with the touchscreen interface. The YoLong electronics team can create a custom-designed brewery control system – semi-automatic or fully automatic – according to our client’s requirements.

As a brewery owner, you will know that one of the hardest tasks involves CIP (Cleaning in Place). Manual labor-intensive work in any craft brewery can be significantly lightened by automation – and automation is made easier with a TC Control (touchscreen) System. No matter what size and capacity your operation, it will go more smoothly with a YoLong Automated Control System.

Brewhouse YoLong TC Systems Automation Areas

- Mash water start

- Vorlauf start (What Does Vorlauf Mean?)

- Lauter tun to Kettle start

- Sparge start via automated mixing water

- Whirlpool start

With this automated control system, you can monitor working conditions on your smart device as long as you have access to internet.

Monitor:

- Pressure

- Temperature

- Cellar tanks – glycol tank, fermenters, brite beer tanks, etc.

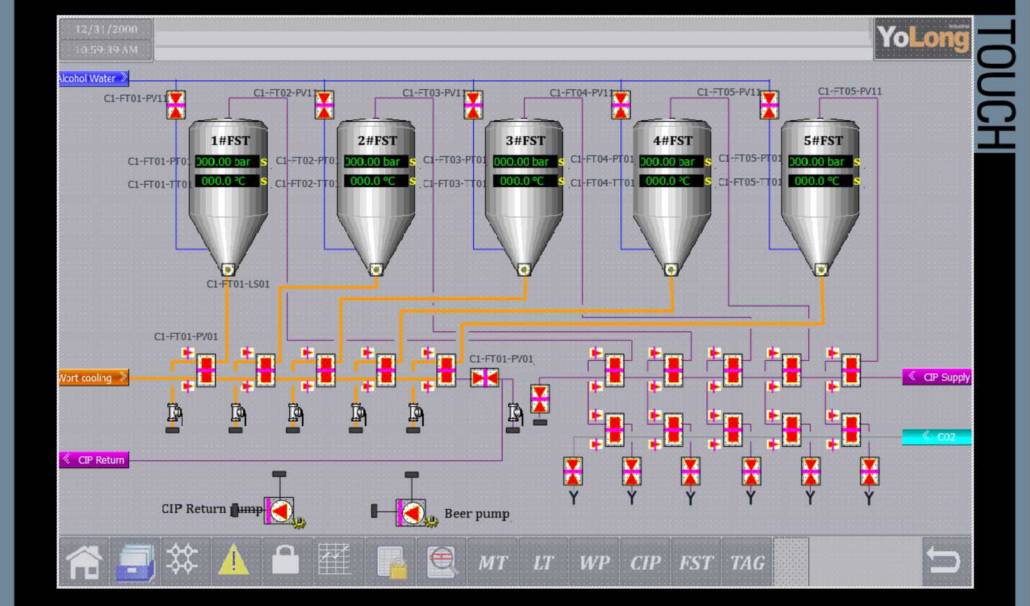

2. PC Control System

YoLong’s PC Control is a centralized computer control system specifically developed for breweries. Each system comes with CE / UL / CUL certified control cabinet; the electronic components are compatible with setups anywhere in the world. YoLong is proud to integrate Siemens and A-B programs and software into the development of our custom PC control systems.

Whether you have a craft brewery with a capacity of 30bbl or a brewhouse with a capacity above 100bbl, a YoLong Process Control System gives you everything you need for the automation, monitoring, and control over your brewery.

Benefits of PC Control

- Labor reduction – both on-floor and in staff hours

- Improved quality of beer

- Improved control of recipe consistency

- Automatic temperature settings, material flow, cellar tanks (fermentation tank, brite beer tank, etc.)

- Billing and receipts made easier

- Ordering made easier

- Streamlined and efficient energy recovery

- System configuration for Ethernet Link

- Real-time communication with other automated process equipment

Large brewing system. Full auto Brewhouse controls

Large brewing system_Full auto Cellar controls

Full-auto system can equip with Internet functions, including faults log, date output, material matching, remote control etc.(display on cellphone or PC).

Design Conception