Two options for fermentation control system

/Update June 06,2022 / By YoLong Brewtech

With the vigorous development of the beverage industry, the production of beer is one of the largest technologically advanced industries. Currently, the correct operation of fermentation control systems has shifted to continuous monitoring.

An updated and modern fermentation control system that will improve product quality, reduce production costs and ensure safety. Today we will discuss this topic with YoLong’s fermentation control system.

If you are having questions about your brewing equipment and fermentation controls, please contact YoLong’s team of engineers to find out.

In terms of the beer fermentation control, there’re mainly two options are used and considered:- Temp controllers cabinet_

Start Today

Temp Control System:-

The T-C control system will be a more cost-effective option than the PLC when there are not too many sets of FV & BBT in the brewery, Also easy for trouble-shooting and once any malfunctions happened and no need to get the programmer to solve as any electrician will be able to get these done like replacing the temp controllers. Obviously, for the old-school brewers, the T-C cabinet looks also simple and gorgeous.

But in fact, the setting and detected data isn’t very visible on the T-C Control system, also before going into the following fermentation stages that need to be re-set manually, For different beer recipes that the fermentation status like temp & timing need to be recorded manually as well, In some sense that won’t be accurate than the PLC option.

ARE YOU HAVE BREWING QUESTIONS?

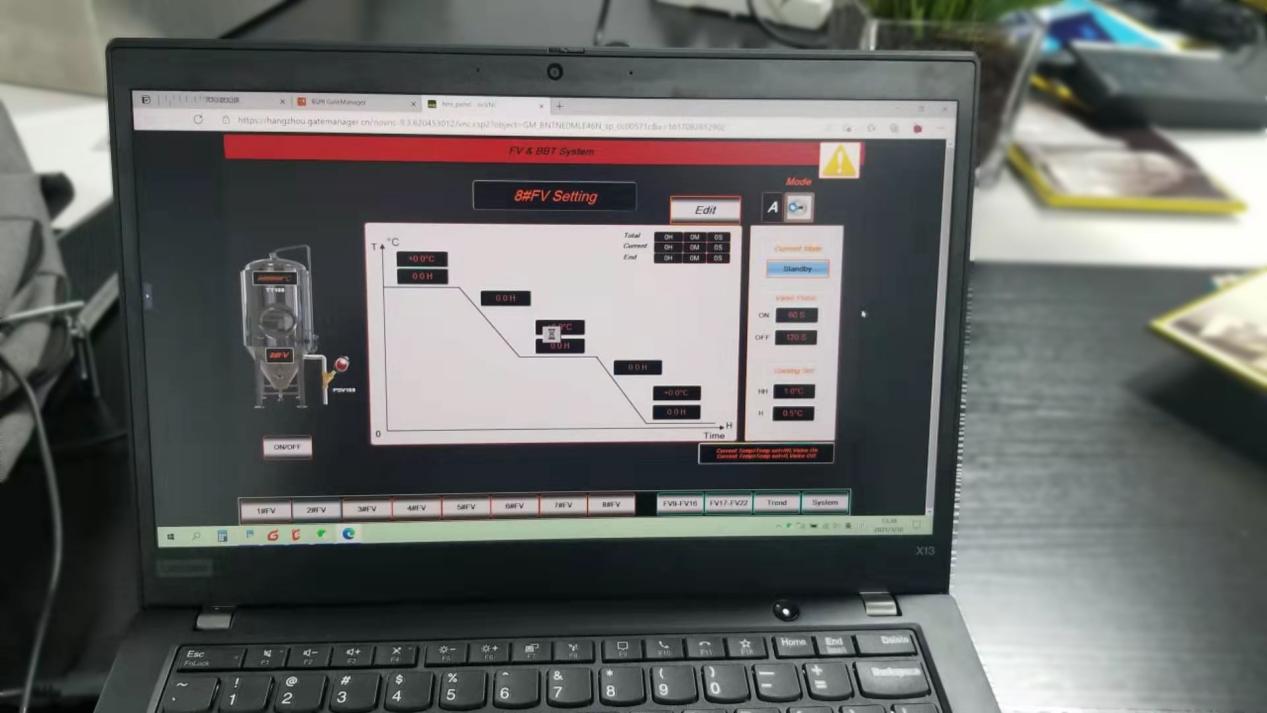

PLC + HMI Combo system:-

For every fermentation that will cost a few days/weeks and there’s no way for the brewer to keep on duty for 24h. Although for the small-scale brewery the PLC is an expensive option. however, it will provide more flexibility and reliability in the future.

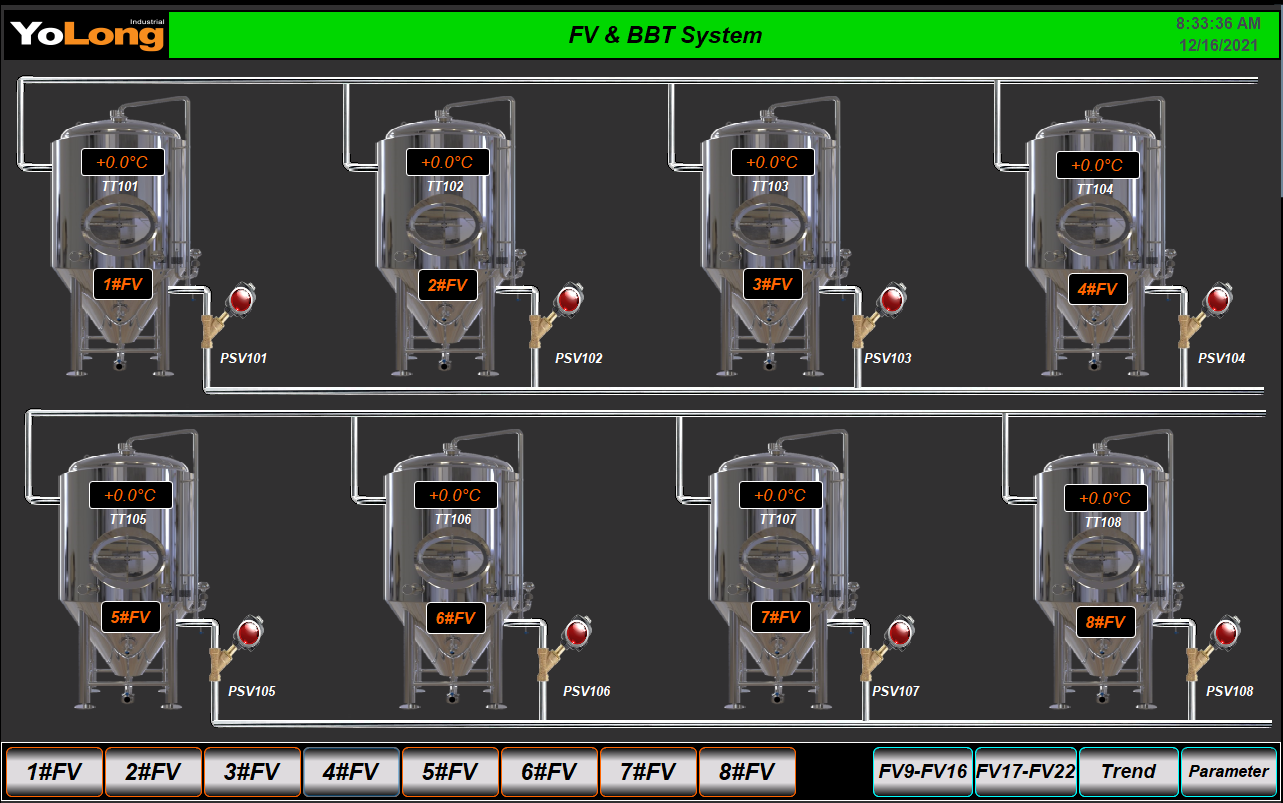

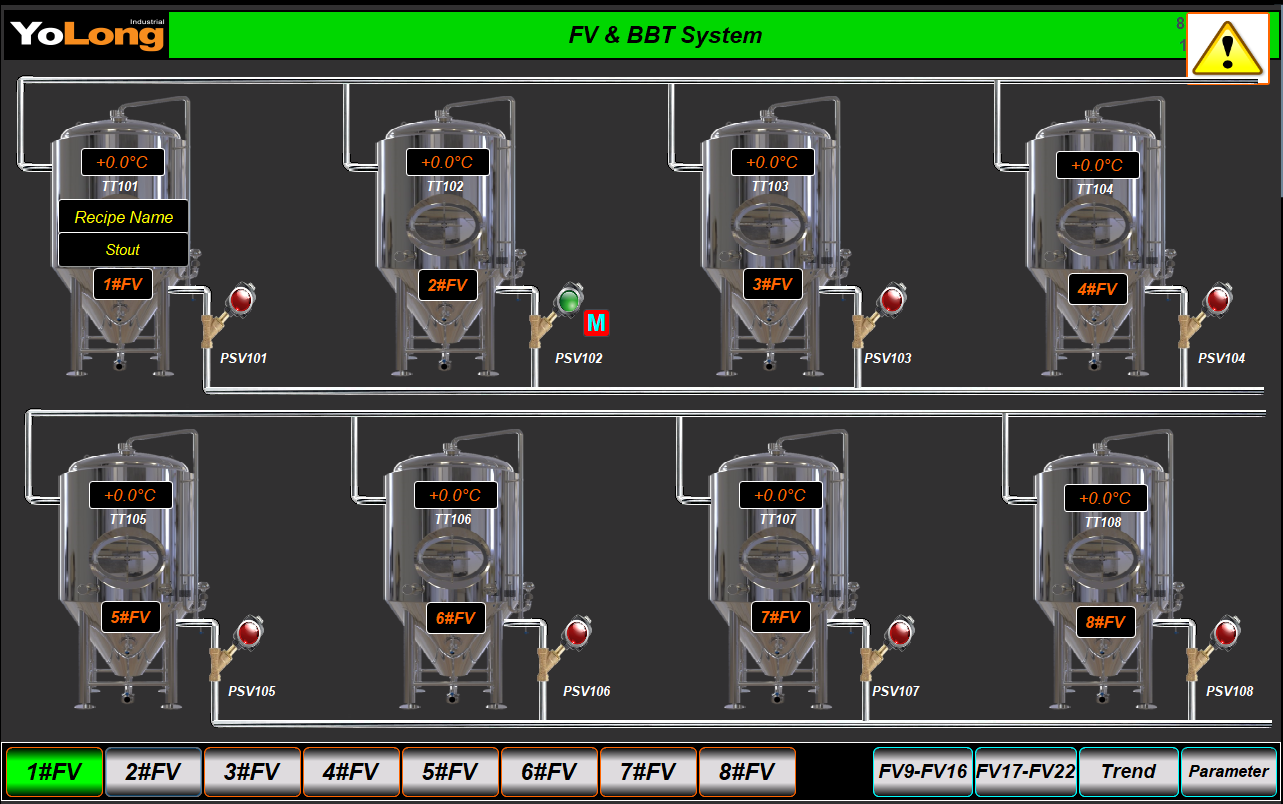

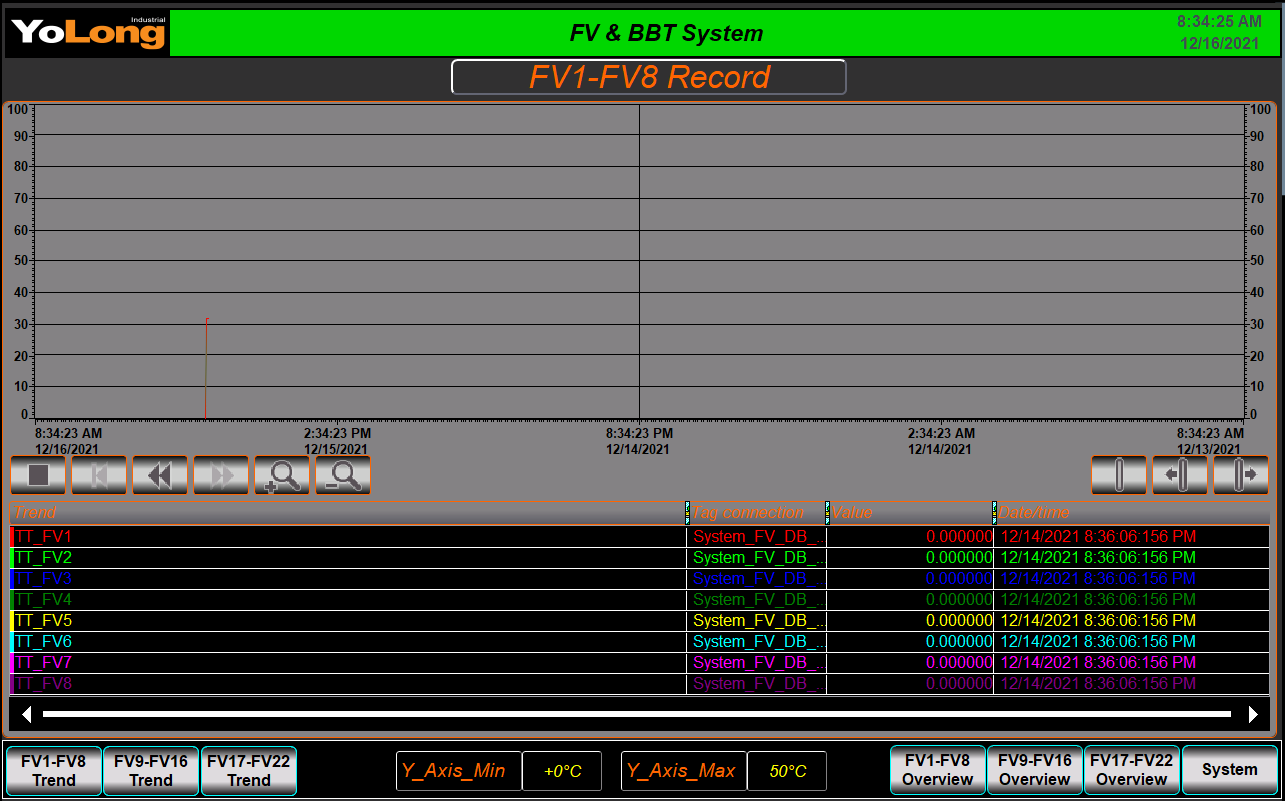

- For the brewery with plenty of cellar tanks, the PLC will be able to manage the tanks intensively and will also spend much more space than a T-C Cabinet, Also the fermentation status of each tank will be visible on the HMI.

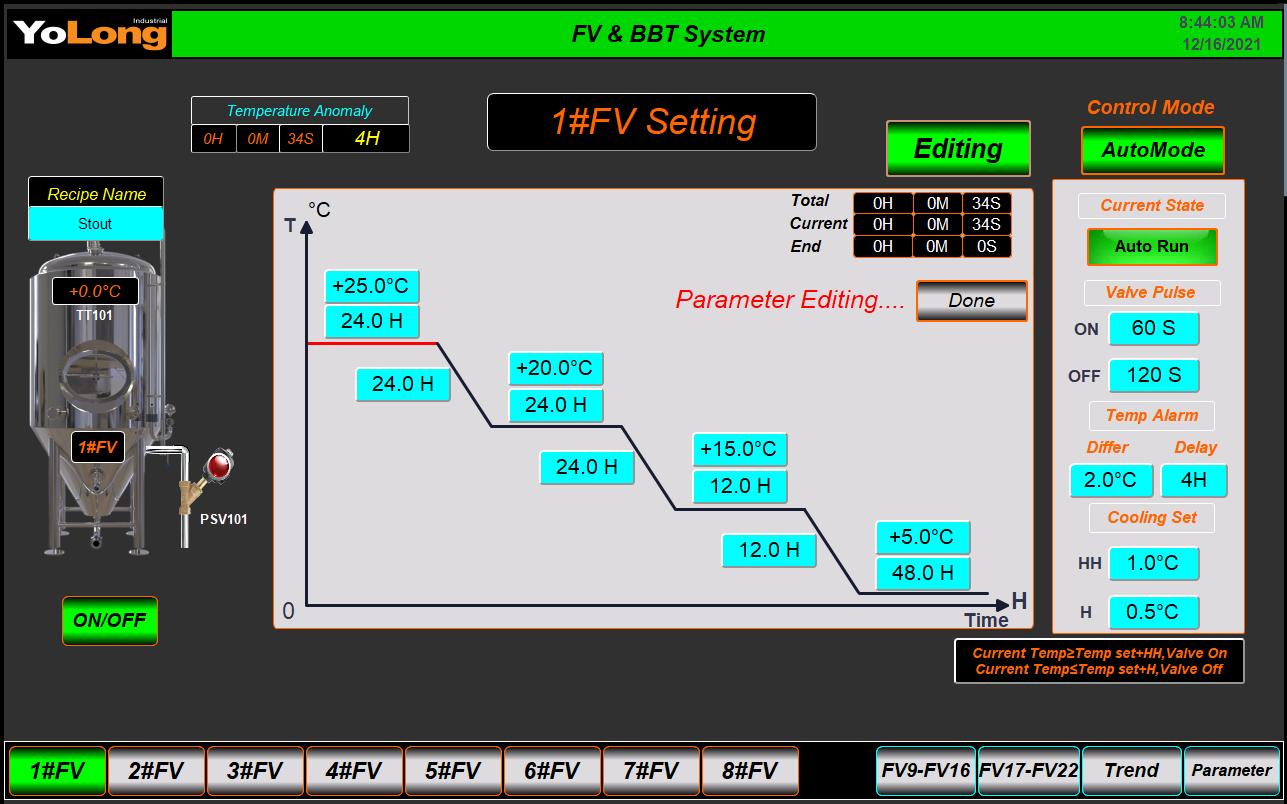

- 2. Then for different brew recipes, the several fermentation steps could be set on the programming together, And the programming will be proceeding the different steps automatically based on the setting data of timing/temp, etc. More accuracy and flexibility than the first option.

- 3. Alarming: By the programming, there’re many abnormities that could be detected and alarmed, like abnormal fermentation temp, and abnormal glycol temp, so this option could avoid the issues happened caused by the temp sensor malfunctions, and promise the fermentation stage going smoothly.

- 4. Any operation before getting done on the programming that the password required, so that also helps to reduce the possibility of the unprofessional person’s wrong operation.

- 5. With HMI, For each tank, the fermentation curve is also very visible.

- 6.In addition, if the budget is still considerable, we can add the site manager in the PLC combo, and then we can have remote access available which also means that we can supervise and control the fermentation on your phone anywhere.

BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to nano brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- 1:Help expand your recipes.

2:Learn how the Nano brewing system works

3:Convince potential clients that you are on the right track.

4:Be your most reliable “brewery problem solver” partner

5:Make your commercial brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

ARE YOU HAVE BREWING QUESTIONS?

WE CAN HELP!

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!