7 Barrel Brewing System: Everything You Need to Know

If you’re planning to start a microbrewery, then you need to know about the equipment that goes into it. One of the most critical pieces of equipment is the brewing system. While there are different types and sizes of brewing systems, the 7 barrel brewing system is one of the most popular choices. In this article, we’ll cover everything you need to know about the 7 barrel brewing system.

What is a 7 barrel brewing system?

A 7 barrel brewing system is a type of brewing equipment used for producing beer. The term “barrel” in the brewing industry refers to a volume measurement equivalent to 31 US gallons or 26 imperial gallons. Therefore, a 7 barrel brewing system can produce 217 US gallons or 181 imperial gallons of beer in one batch.

How does a 7 barrel brewing system work?

A 7 barrel brewing system works by following a series of steps. Firstly, the grains are milled and added to the mash tun. Water is added to the mash tun, and the mixture is heated to a specific temperature to activate the enzymes in the grains that convert the starches to sugar. The resulting liquid, called wort, is transferred to the boil kettle, where it is boiled with hops to add flavor and bitterness to the beer. After boiling, the wort is cooled in the wort chiller and transferred to the fermenters, where yeast is added to ferment the sugar into alcohol.

Benefits of a 7 barrel brewing system

There are many benefits of a 7 barrel brewing system, which makes it a popular choice for many microbreweries. Here are some of the benefits:

Economical

Compared to larger brewing systems, a 7 barrel brewing system is more economical as it requires less space, water, and power. It also has a lower initial investment cost and is easier to operate and maintain.

Efficient

A 7 barrel brewing system is designed to be efficient, with a high level of automation, which makes it easier to use and reduces the risk of errors. It also has a shorter brewing time, which means you can produce more beer in less time.

Versatile

A 7 barrel brewing system can produce a wide range of beer styles, from light lagers to heavy stouts. It also allows for experimentation with different ingredients and brewing techniques.

Scalable

A 7 barrel brewing system is scalable, which means you can increase your production capacity by adding more fermenters or upgrading to a larger brewing system.

Consistent

A 7 barrel brewing system is designed to produce consistent beer batches, which means you can maintain the quality and flavor of your beer from batch to batch. This is important for building a loyal customer base and maintaining your brand reputation.

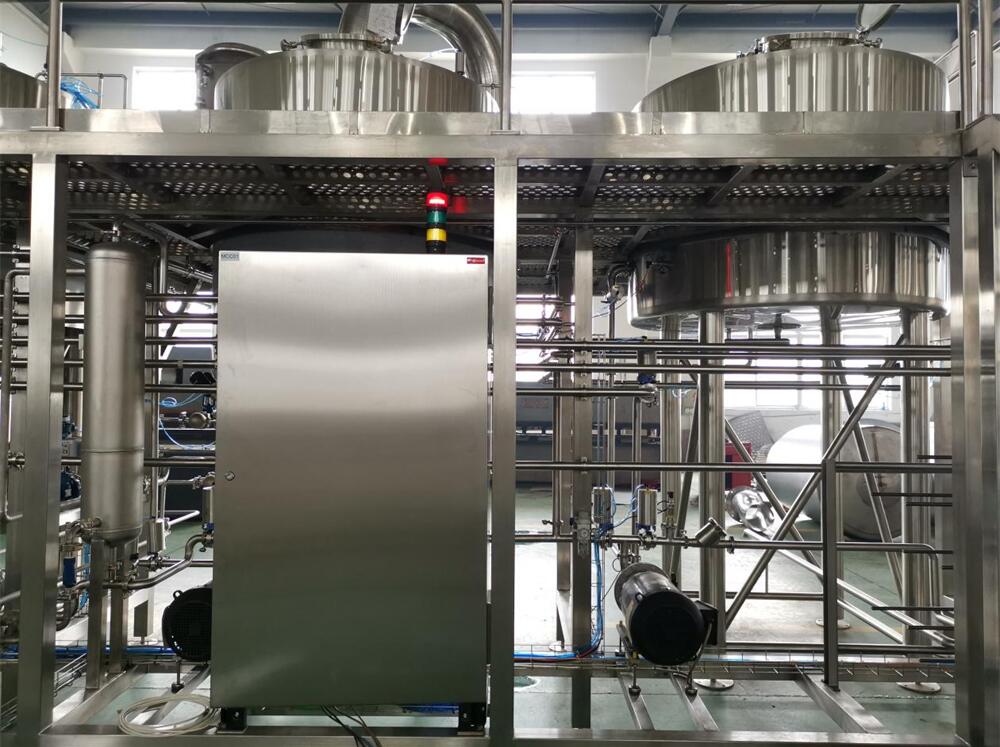

Features of a 7 barrel brewing system

A 7 barrel brewing system is composed of several key components. Here are some of the features you can expect from a typical 7 barrel brewing system:

Mash Tun

The mash tun is where the grains are mixed with water to activate the enzymes that convert the starches to sugar. The mash tun is insulated to maintain a constant temperature and can be heated using direct fire, electric, or steam.

Boil Kettle

The boil kettle is where the wort is boiled with hops to add flavor and bitterness to the beer. The boil kettle is also insulated and can be heated using direct fire, electric, or steam.

Hot Liquor Tank

The hot liquor tank is used to store hot water that is used in the brewing process. It can also be used to preheat the water before it is added to the mash tun.

Wort Chiller

The wort chiller is used to cool the boiled wort before it is transferred to the fermenters. It can be cooled using either water or glycol.

Fermenters

The fermenters are where the yeast is added to ferment the sugar into alcohol. Fermenters come in various sizes and can be made from stainless steel, plastic, or wood.

Factors to consider when choosing a 7 barrel brewing system

When choosing a 7 barrel brewing system, there are several factors to consider:

Space

A 7 barrel brewing system requires a significant amount of space, both for the brewing equipment and for storing the finished beer. Ensure that you have enough space before investing in a 7 barrel brewing system.

Budget

A 7 barrel brewing system can be a significant investment, so it’s essential to have a budget in mind before making a purchase.

Production needs

Consider your production needs before choosing a 7 barrel brewing system. If you plan to expand your business in the future, you may want to choose a system that is scalable.

Power requirements

Different types of 7 barrel brewing systems have different power requirements. Ensure that your facility can accommodate the power needs of your chosen system.

Maintenance and care of a 7 barrel brewing system

Maintaining and caring for your 7 barrel brewing system is crucial to ensure that it operates efficiently and produces high-quality beer. Here are some tips for proper maintenance and care:

Regular Cleaning

Regular cleaning is essential to remove any dirt, debris, or bacteria that may be present in the brewing system. Ensure that you clean all parts of the system thoroughly, including the mash tun, boil kettle, hot liquor tank, wort chiller, and fermenters. Use a cleaning solution that is specifically designed for brewing equipment and follow the manufacturer’s instructions.

Sanitization

Sanitization is critical to prevent contamination and ensure that your beer is safe to drink. Use a sanitizer that is appropriate for brewing equipment, and ensure that you follow the manufacturer’s instructions. Sanitize all parts of the system, including hoses, valves, and fittings.

Maintenance

Regular maintenance is necessary to ensure that your brewing system operates efficiently and produces high-quality beer. Check all parts of the system regularly for signs of wear and tear and replace any damaged parts immediately. Lubricate any moving parts as needed and tighten any loose bolts or fittings.

Spare Parts and Supplies

Ensure that you have spare parts and supplies on hand in case of equipment failure. This includes replacement hoses, valves, and fittings, as well as cleaning and sanitizing solutions. Keeping spare parts on hand will help you avoid any downtime in production and keep your brewing system operating efficiently.

In conclusion, regular cleaning, sanitization, maintenance, and having spare parts and supplies on hand are essential to maintaining and caring for your 7 barrel brewing system. By following these tips, you can ensure that your brewing system operates efficiently and produces high-quality beer consistently.

Conclusion

A 7 barrel brewing system is an excellent choice for a microbrewery. It’s economical, efficient, versatile, scalable, and produces consistent beer batches. When choosing a 7 barrel brewing system, consider factors such as space, budget, production needs, and power requirements. Finally, remember to maintain and care for your equipment to ensure that it operates efficiently and produces high-quality beer.

Thank you for reading this blog about 7 barrel brewing system. If you’re looking for a high-quality, durable, and easy-to-use 7 barrel brewing system, we recommend the brewing equipment brand Yolong Brewtech. Yolong brewing equipment has a good reputation in the market, and their products’ quality and reliability have stood the test of time. To learn more, visit our product page and browse our brewing system products.

- automated brewing system

- commercial beer brewing systems

- professional beer brewing

- brewhouse setup

- micro brewery startup

- brewery design

Additional FAQs about a 7 Barrel Brewing System

- Q: What cellar capacity pairs best with a 7 barrel brewing system?

A: Plan 3–5× brewhouse volume in fermentation capacity (21–35 bbl total) plus at least one 7–10 bbl brite tank. This supports 2–4 weekly turns and seasonal beers. - Q: Steam, direct fire, or electric for a 7 bbl brewhouse?

A: Steam offers even heat and scalability; direct fire is lower CAPEX but needs robust ventilation; electric can work where power is available and demand charges are manageable. - Q: What brewhouse efficiency should I expect?

A: Well‑tuned 7 bbl systems typically achieve 70–85% brewhouse efficiency with proper crush, lauter design, and runoff control. - Q: How do I control oxygen pickup on a 7 bbl system?

A: Use closed transfers, purge lines/vessels with CO2, employ deaerated water for dilution, and monitor DO at knockout and pre‑package. Target knockout DO <0.10–0.30 ppm; package DO <50–100 ppb. - Q: What utilities should I forecast before purchase?

A: Confirm 208–240 V (or 400–480 V) 3‑phase power, steam or gas availability, glycol chiller capacity sized for concurrent fermentations and crash cooling, potable water flow/pressure, and wastewater handling.

2025 Industry Trends for 7 Barrel Brewing Systems

- Modular automation: stepwise upgrades (PID mash control, boil‑off management, lauter ΔP, sensor‑led CIP) improve repeatability without full SCADA.

- Electrification and hybrid heating: electric HLTs or hybrid kettles used to navigate gas permitting and peak demand charges.

- Data‑driven QA: electronic batch records (EBR), CIP logs, and inline/package DO checks become standard even at 7 bbl scale.

- Utility optimization: heat recovery from wort-to-liquor, thicker vessel insulation, and VFD pumps cut utilities 10–20%.

- Faster installs: FAT‑tested, pre‑wired skids and IO‑Link sensors reduce commissioning to 1–2 weeks in prepared sites.

2025 Benchmarks and Cost Signals for a 7 Barrel Brewing System

| Metric | Typical Target/Range | Notes |

|---|---|---|

| Turnkey 7 bbl brewhouse CAPEX | ~$140k–$350k+ | Heat source, finish, automation, and vendor drive price |

| Brewhouse efficiency | 70–85% | Depends on crush, lauter design, runoff profile |

| Water-to-beer ratio | 3.2–4.8:1 | Heat recovery and optimized CIP reduce water use |

| Knockout DO | <0.10–0.30 ppm | Closed knockout and deaerated water help |

| Package DO | <50–100 ppb | Shelf life driver for local distro |

| Electrical service (electric heat) | 100–200 A @ 208–240 V 3φ | Site specific; verify with OEM |

| Commissioning timeline | 7–14 days (prepared site) | FAT modular skids on the low end |

Sources: Brewers Association Quality and Sustainability benchmarking; Master Brewers Association of the Americas (MBAA) Technical Quarterly; OEM application notes and supplier datasheets (2024–2025). Verify against local codes and utilities.

Latest Research Cases

Case Study 1: Closed Transfers + Spunding Extended Freshness at 7 bbl (2025)

- Background: A taproom‑focused brewery running a 7 barrel brewing system saw hop fade by day 45 and variable package stability.

- Solution: Implemented CO2 purging SOPs for hoses/vessels, added pressure‑rated unitanks (2.0–2.5 bar), spunded at 0.8–1.0 bar near terminal gravity, and performed inline DO spot checks at knockout and pre‑package.

- Results: Median package DO dropped from 138 ppb to 67 ppb; sensory staling notes reduced ~50% at day 60; average tank time shortened by ~1 day.

Case Study 2: Sensor‑Led CIP Reduced Utilities Without Quality Risk (2024)

- Background: A 7 bbl brewpub had high water/chemical consumption and inconsistent cleaning outcomes.

- Solution: Added conductivity/time/flow endpoints, validated spray device coverage and return flow, and logged CIP cycles in an HMI for training/audit.

- Results: Water per CIP −17%; caustic use −19%; CIP time −10–14 minutes; zero CIP‑related quality holds over six months.

Sources: Brewers Association Quality and Sustainability resources; MBAA Technical Quarterly articles on oxygen control, CIP validation, and heat recovery; manufacturer technical guides. Outcomes vary by SOPs and site conditions.

Expert Opinions

- Mary Pellettieri, Brewing Quality Consultant; Author, “Quality Management for Breweries”

- Viewpoint: “Invest first in cleanability and oxygen control on a 7 barrel brewing system—validated CIP and closed transfers protect flavor and margins.”

- Reference: Brewers Association Quality resources (https://www.brewersassociation.org/)

- John Mallett, Former VP Operations, Bell’s Brewery; Author, “Malt”

- Viewpoint: “Specify weld quality, surface finish, jacket zoning, and reliable instrumentation before advanced automation—fundamentals pay back every brew.”

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

- Viewpoint: “Thermal history and oxygen exposure from mash through packaging determine whether hop expression survives to the glass.”

Practical Tools and Resources

- Brewers Association: Quality, Safety, Sustainability toolkits — https://www.brewersassociation.org/

- Master Brewers Association of the Americas (MBAA) Technical Quarterly — https://www.mbaa.com/

- Standards/compliance: ASME BPVC; EU PED; UL/CE — https://www.asme.org/ and https://single-market-economy.ec.europa.eu/

- Production/QA software: Ekos — https://www.getekos.com/; OrchestratedBEER/NetSuite — https://www.netsuite.com/

- Recipe/process tools: Brewfather — https://brewfather.app/; BeerSmith — https://beersmith.com/

- DO/CO2 instrumentation: Anton Paar — https://www.anton-paar.com/; Haffmans/Pentair — https://foodandbeverage.pentair.com/; Zahm & Nagel — https://zahmnagel.com/

- Sanitation chemistry and validation: Five Star Chemicals — https://fivestarchemicals.com/

- Equipment marketplace/directories: ProBrewer Classifieds — https://www.probrewer.com/; Brewers Association Supplier Directory

Last updated: 2025-09-04

Changelog: Added 5 targeted FAQs for 7 bbl systems; included 2025 trends with a benchmarks/cost table; provided two case studies on oxygen control and sensor-led CIP at 7 bbl scale; added expert viewpoints; curated practical tools/resources with authoritative links.

Next review date & triggers: 2026-03-01 or earlier if BA/MBAA update small-brewery benchmarks, oxygen/CIP guidance changes, or OEM innovations affect 7 bbl brewhouse specifications and commissioning best practices.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?