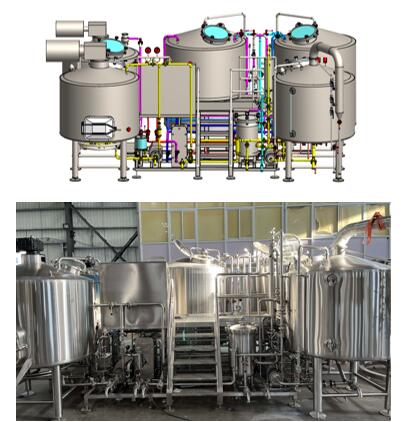

LARGE MICRO BREWERIES

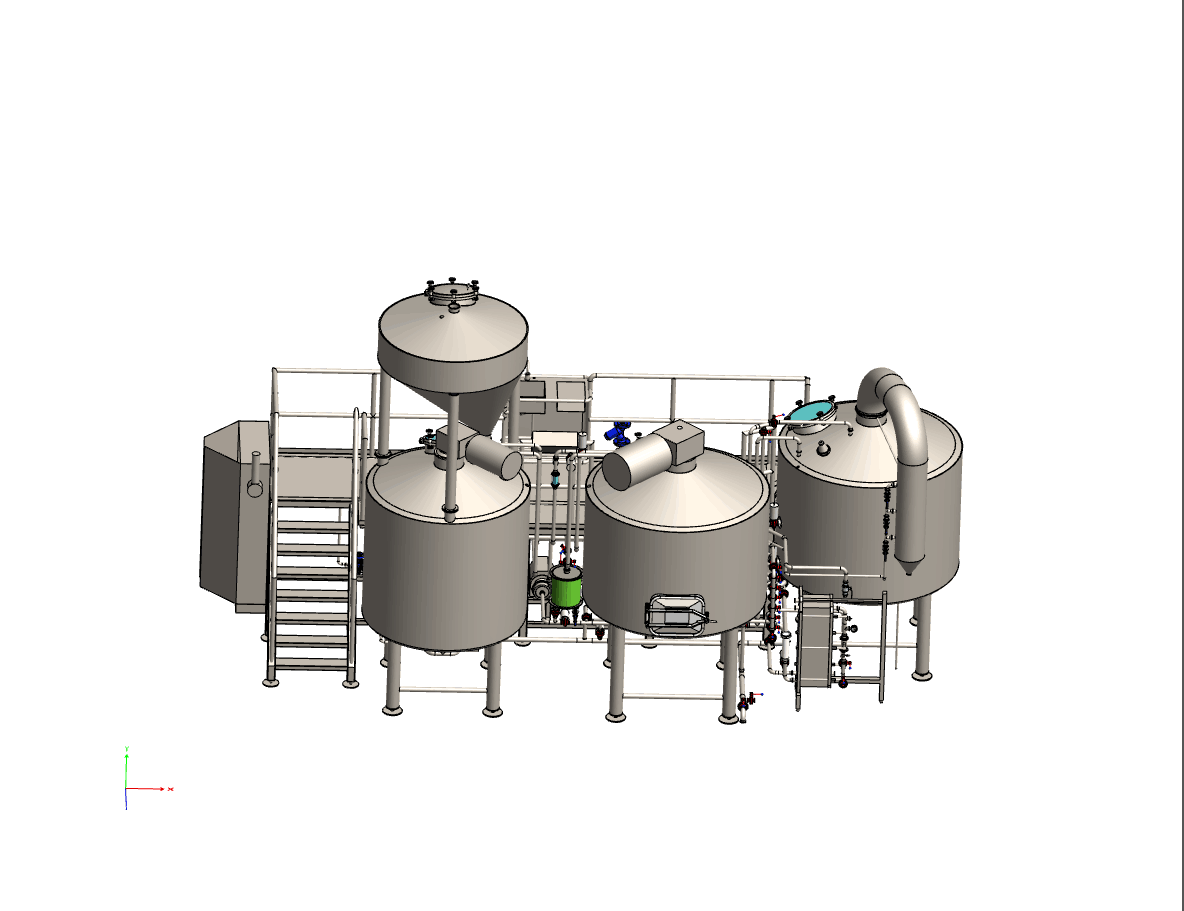

COMPLETE BREWING EQUIPMENT OF LARGE SCALE, MULTI-VESSEL, 5-30BBL BREWERY PRODUCTION

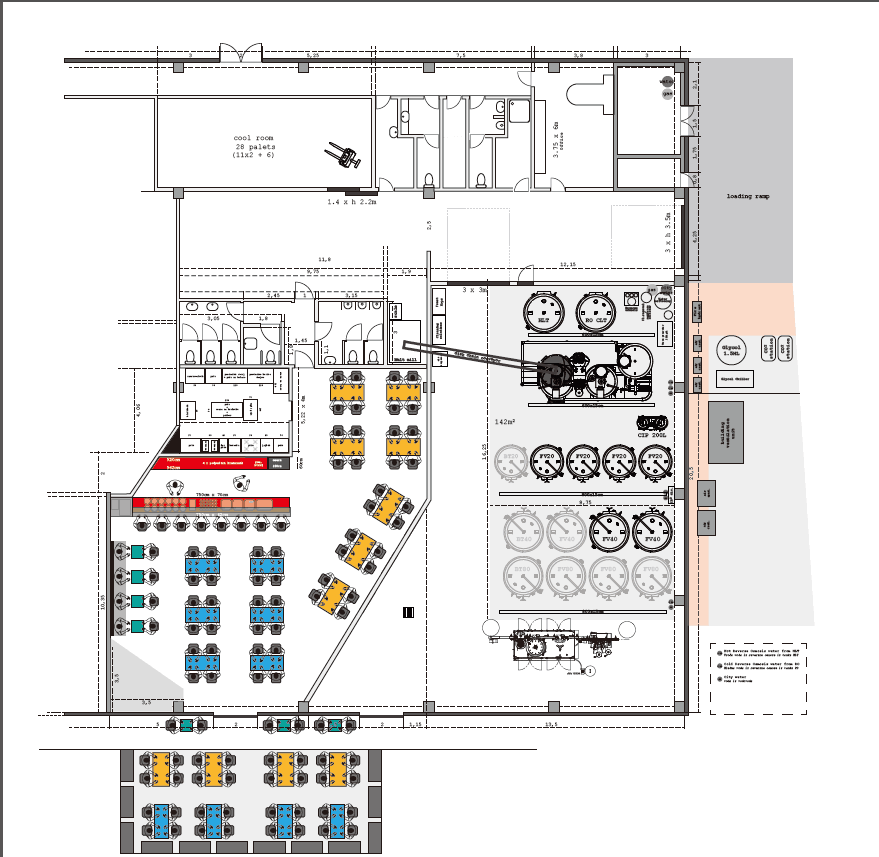

MICRO-BREWERIES

The 10HL 2 vessels Electric heating small brewery equipment is the Site-Size & Budget-Friendly Custom Designed Equipment.

This brewing system also has customized beer solutions, reliable quality and delivery time, professional project manager and engineer technical support. Perfect and active after-sale service, Good user reputation.

- We worked with more than 200+ breweries all world and especially experienced on high-automation fully customized commercial brewery system scope.

We serve every client with design and quality far superior to peers on brewery equipment.

Free consultant and design. we are top Quality Micro Brewery Equipment Manufacturer!

Start Today

Estimating the cost of brewery equipment

The standard brewery configuration and optional equipment options provide customers with a very large budget space for development.

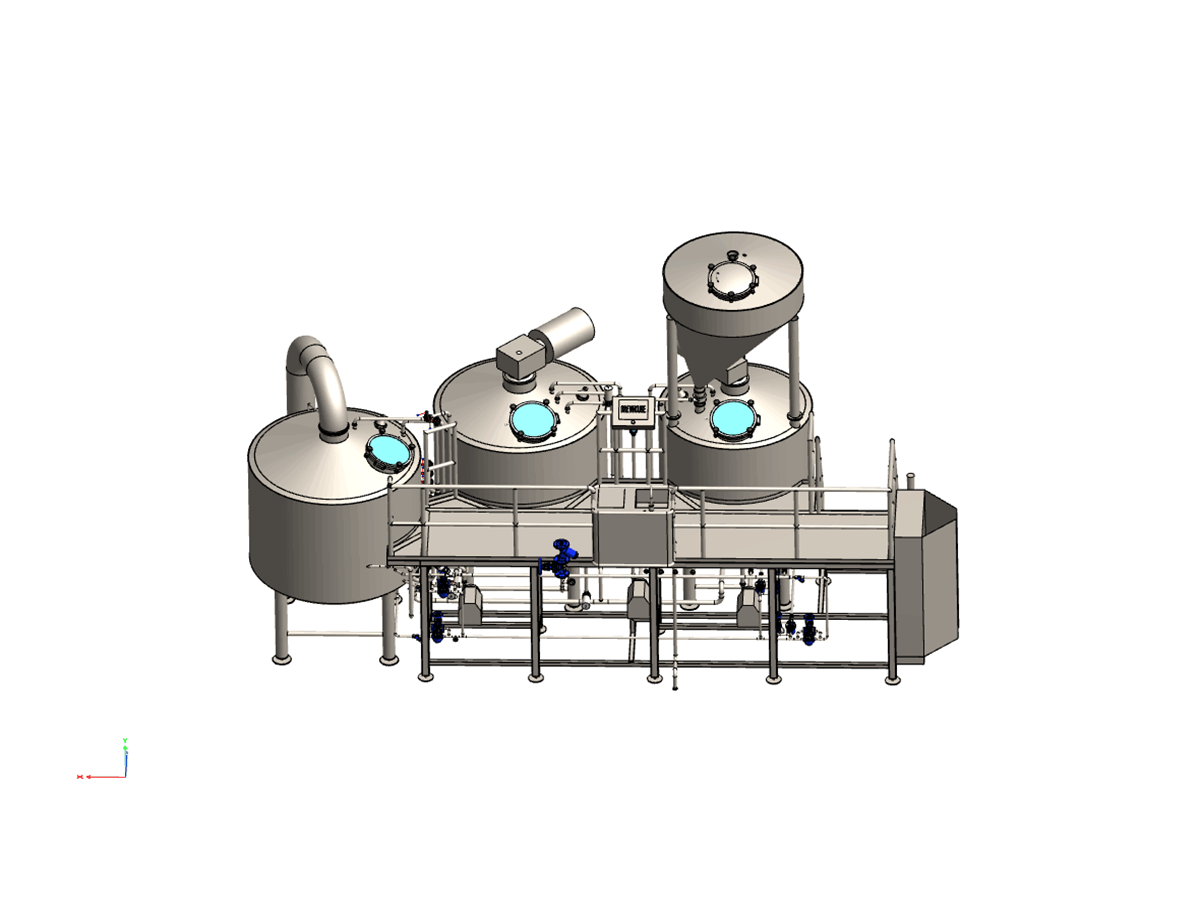

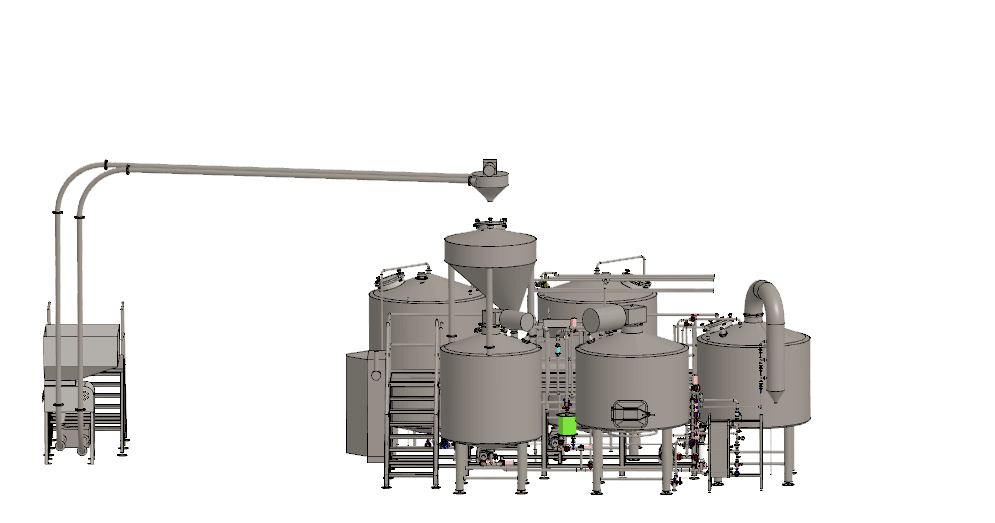

STANDARD PRODUCT FEATURES:

- Three vessels combo brewhouse of MT & LT & KWPT

- Steam heating with relative steam pipelines & fittings

- No.1 PLC + HMI Automation Control system for Brewhouse

- No.2 PLC + HMI Automation Control system for Fermentation

- Automated material flow by all pneumatic valves

- Three Wort VFD pumps included for per MT & LT &KWPT

- Agitator with VFD Regulation

- Rake Knife with VFD Regulation

- Single stage PHE for wort cooling by Cold water supplied from CLT

- Tubular Heat Exchanger for quick wort cool down before whirlpool or sour beer

- Wort Grant & Hop Back & Steam Condenser & Sight Glasses & Sampling Valves

- Flowmeter, Temp Sensor, Level Sensor, Flow transmitter etc for system automation control

- Grain Case placed above Mash Tun, and Connecting the mash tun & mill by chain conveyor

- 50HL Automated Water Station comprises of HLT & CLT

- HLT was steam heating through PHE for the quick efficiency

- CLT was glycol cooling through jackets

- Three Water pumps includes HLT & CLT supply pump & HLT circulation pump

- HLT & CLT level displayed on BH HMI

- HLT & CLT Auto feeding based on the level setting on BH PLC

- HLT & CLT supply pump with auto supply fucntionality by detect the pipe inside pressure

- Pneumatic water supply valves

- Glycol Reservoir

- Suitable chiller for Glycol Reservoir cooling down, and then cool the CLT & FVs

OPTIONS:

- Direct Fire heating optional

- Remote Access functionality

- Four vessels combo brewhouse optional

- Fully Automated CIP functionality optional

- Manual valves optin for the budget saving