LARGE MICRO BREWERIES

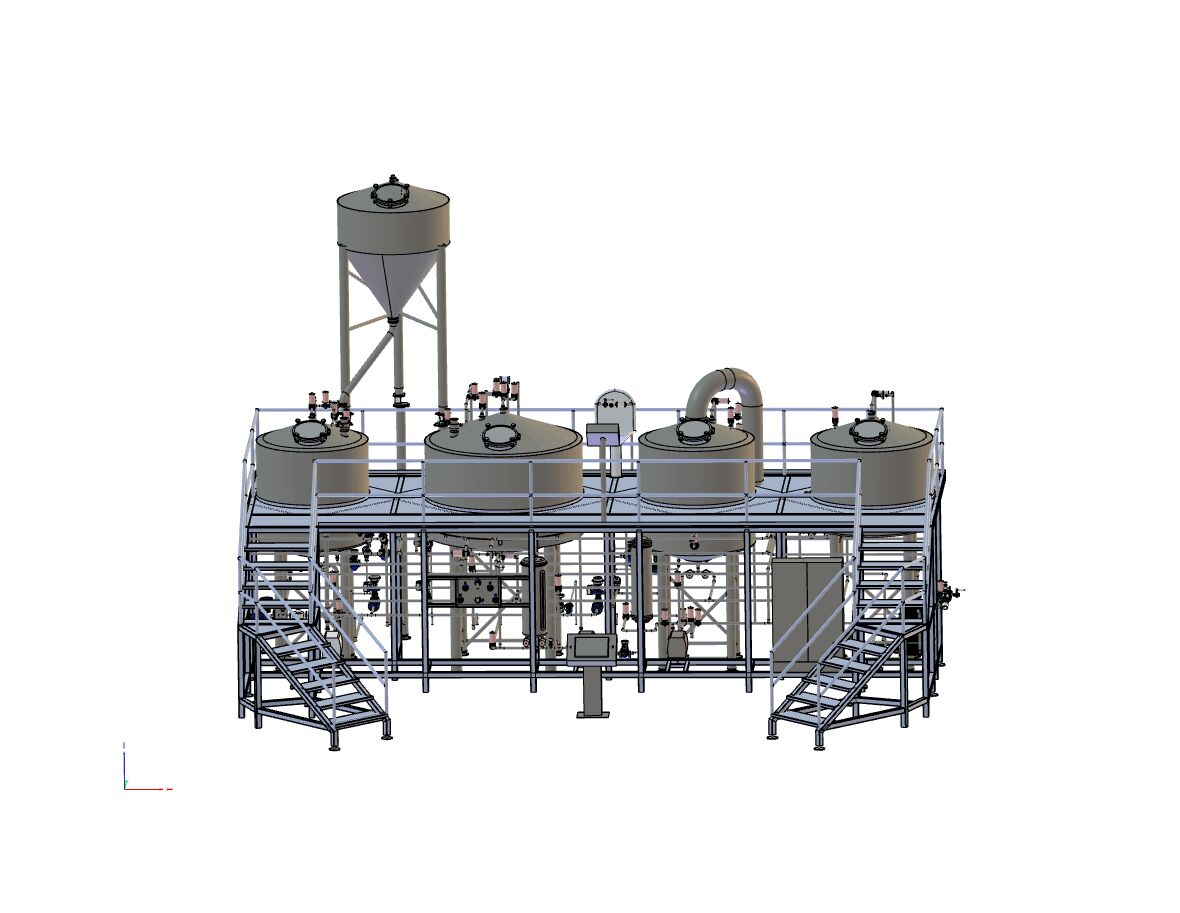

COMPLETE BREWING EQUIPMENT OF LARGE SCALE, MULTI-VESSEL, 5-30BBL BREWERY PRODUCTION

MICRO-BREWERIES

The 10HL 2 vessels Electric heating small brewery equipment is the Site-Size & Budget-Friendly Custom Designed Equipment.

This brewing system also has customized beer solutions, reliable quality and delivery time, professional project manager and engineer technical support. Perfect and active after-sale service, Good user reputation.

- We worked with more than 200+ breweries all world and especially experienced on high-automation fully customized commercial brewery system scope.

We serve every client with design and quality far superior to peers on brewery equipment.

Free consultant and design. we are top Quality Micro Brewery Equipment Manufacturer!

Start Today

Estimating the cost of brewery equipment

The standard brewery configuration and optional equipment options provide customers with a very large budget space for development.

STANDARD PRODUCT FEATURES:

- 1 x Mash Tun with agitator machine and multi steam heating dimple jacket sections

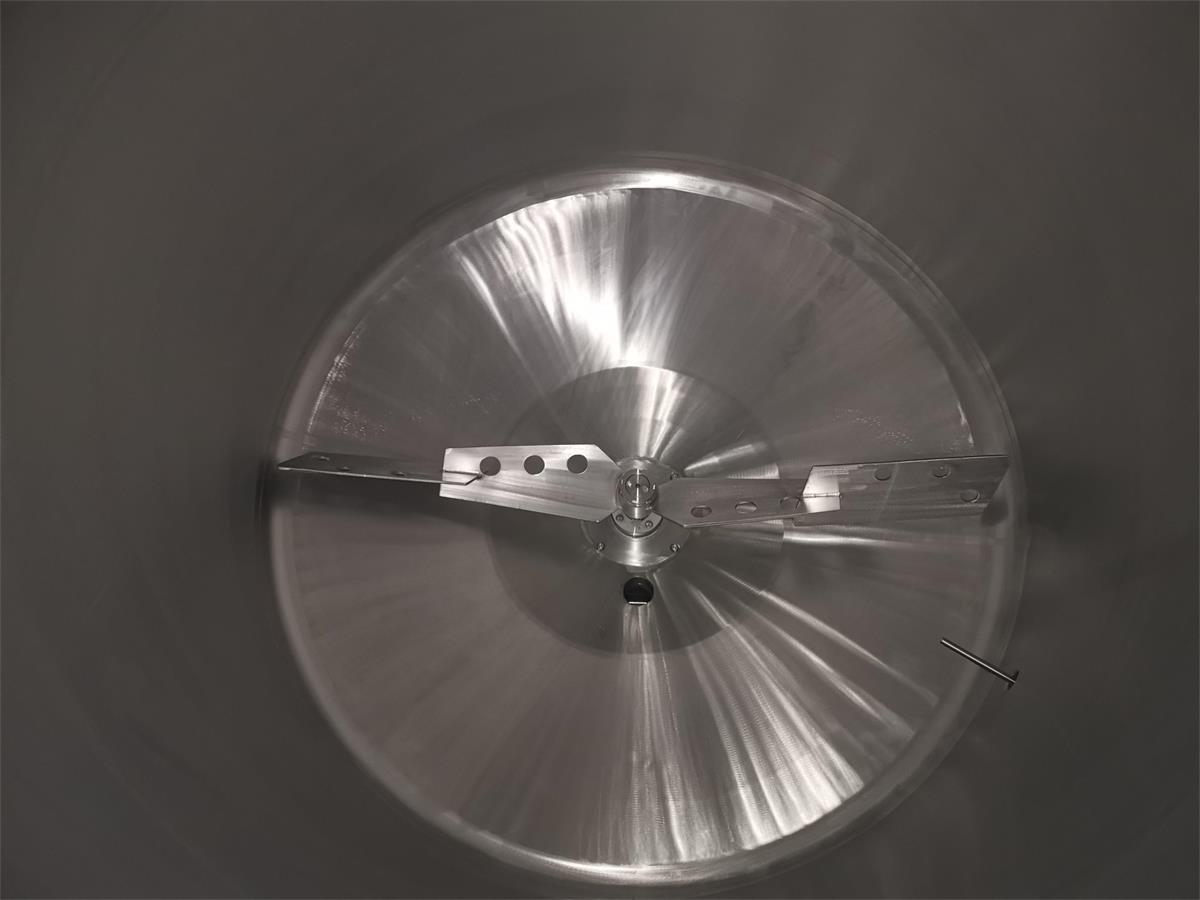

- 1 x Lauter Tun with lautering raking system

- 1 x Kettle Tank with Condensation Device and multi steam heating dimple jacket sections

- 1 x Whirlpool Tank with Tangential Inlet

- 1 x PLC + HMI Automation Control system for Brewhouse

- 1 x PLC + HMI Automation Control system for Fermentation

- Automated material flow by all pneumatic valves

- 6 x Wort VFD pumps included for per MM < &KT &WP &HLT & CLT

- 1 x Rake Knife with VFD Regulation

- 1 x Tubular Heat Exchanger for quick wort cool down before whirlpool or sour beer

- 1 x TRIPLE brew length 304 SS HLT with steam plate heat exchanger

- 1 x TRIPLE brew length cold liquor tank with dual glycol jackets with plate heat exchanger

- 1 x Plate Heat Exchanger for cooling wort

- 1 x Wort Grant and Wort Areation

- 1 x SS work platform with sanitary process piping & sanitary valves

- 1 x Add Sink on working platform

- 1 x SS wort grant

- 1 x Sanitary heat exchanger and wort aeration system

- 1 x Water flow meter after water mixing station for cold and hot water

- 2 x Siemens touch screen control panels

- 6 x Tank light assemblies

- 1 x Mash hydration assembly

- HLT & CLT Auto feeding based on the level setting on BH PLC

- HLT & CLT supply pump with auto supply fucntionality by detect the pipe inside pressure

- Pneumatic water supply valves

- 1 x CAD layouts, installation assistance, assembly, training

OPTIONS:

- 1 x Twin-heads keg washer

- 1 x Manual keg filler

- 1 x Bottle filling& capping machine

- 1 x Grain lift auger

- 1 x Grain mill working platform

- 1 x 3vessels automatic CIP station

- 1 x Pasteurization system

- 1 x 100KG Hop Storm

- 1 x Automatic can filling line

- 1 x Automatic grain drain

- Remote control for brewhouse/cellar tan

- AS/PED certification

- UL/CUL certification