10bbl Fermentation Tank: The Ultimate Guide

What is a 10bbl fermentation tank?

A 10bbl (barrel) fermentation tank is a crucial piece of equipment in the brewing process. It is a stainless steel vessel specifically designed to hold and ferment 10 barrels of beer, equivalent to approximately 310 gallons. These tanks are used by breweries of all sizes, from small craft breweries to larger commercial operations.

Importance in the brewing process

Fermentation is the heart of the beer-making process, where yeast converts sugars into alcohol and carbon dioxide. A 10bbl fermentation tank provides an optimal environment for the yeast to work its magic, ensuring consistent and high-quality results.

Components and Features

Material and construction

10bbl fermentation tanks are typically made from high-grade stainless steel, which offers excellent durability and corrosion resistance. This material also provides a smooth, non-porous surface that’s easy to clean and sanitize. The tanks are usually constructed with a conical bottom, which aids in the collection and removal of yeast and sediment.

Temperature control system

A key aspect of successful fermentation is maintaining the right temperature. 10bbl fermentation tanks are equipped with a glycol cooling system that helps maintain a consistent temperature throughout the fermentation process. This system typically consists of cooling jackets, a glycol reservoir, and a temperature control unit.

Pressure control and relief

To ensure the safe fermentation process, pressure relief valves are installed in 10bbl fermentation tanks. These valves protect the tank from over-pressurization by releasing excess pressure if needed. Some tanks also feature adjustable pressure control to fine-tune the fermentation environment.

Cleaning and sanitation

Maintaining cleanliness and sanitation is essential in the brewing process. 10bbl fermentation tanks are designed with easy-to-clean surfaces and CIP (clean-in-place) systems. The CIP system circulates cleaning and sanitizing solutions through the tank and its components, ensuring a thorough and efficient cleaning process.

Choosing the Right 10bbl Fermentation Tank

Budget considerations

When selecting a 10bbl fermentation tank, it’s essential to consider your budget. Prices can vary widely depending on the tank’s features and manufacturer. Do your research and compare prices to find the best fit for your needs.

Space requirements

Consider the available space in your brewery when choosing a 10bbl fermentation tank. Ensure there’s enough room for the tank and any additional equipment, like glycol chillers and temperature control systems. Don’t forget to consider access points for installation and maintenance.

Production volume

Evaluate your current production volume and future growth plans when selecting a 10bbl fermentation tank. Ensure the tank’s capacity aligns with your brewery’s production requirements. If you anticipate significant growth, consider investing in a larger tank or planning for additional tanks to accommodate your expansion.

Expansion plans

When planning for the future, consider how easily you can add more fermentation tanks to your brewing setup. Make sure the design and layout of your brewery allow for easy expansion and the seamless integration of new equipment.

Benefits of Using a 10bbl Fermentation Tank

Improved product quality

First and foremost, using a 10bbl fermentation tank enhances the quality of your beer. It achieves this by providing excellent temperature and pressure control, which directly influences the final product. Consequently, you can expect a more uniform brew, free of off-flavors and other undesirable traits. In essence, a 10bbl fermentation tank sets the stage for an exceptional brewing experience.

Increased efficiency

Next, 10bbl fermentation tanks are designed to streamline the brewing process. For instance, the conical bottom and CIP systems simplify yeast collection and cleaning, respectively. As a result, you can reduce downtime and labor costs, allowing you to focus more on crafting delectable beers. In short, a 10bbl fermentation tank paves the way for a more efficient brewing operation.

Scalability

Another advantage of using a 10bbl fermentation tank is its scalability. This tank size is versatile enough to accommodate small-batch brewing as well as larger-scale operations. Therefore, as your brewery grows, you can easily scale your production to meet increasing demand. In other words, investing in a 10bbl fermentation tank is a wise long-term decision for your brewery.

Cost-effectiveness

Lastly, a high-quality 10bbl fermentation tank can save you money in the long run. The durable stainless steel construction ensures longevity, while the advanced temperature and pressure control systems minimize waste and improve overall product quality. In summary, a 10bbl fermentation tank is a cost-effective solution that adds value to your brewing business.

In conclusion, a 10bbl fermentation tank offers numerous benefits, such as improved product quality, increased efficiency, scalability, and cost-effectiveness. These advantages make it an indispensable piece of equipment for breweries of all sizes.

Conclusion

A 10bbl fermentation tank is an essential piece of equipment for any brewery, offering numerous benefits such as improved product quality, increased efficiency, scalability, and cost-effectiveness. By carefully considering your budget, space requirements, production volume, and expansion plans, you can select the perfect 10bbl fermentation tank for your brewery’s needs.

Frequently Asked Questions

- What is the average cost of a 10bbl fermentation tank? The cost of a 10bbl fermentation tank can vary significantly depending on the manufacturer and features. Prices can range from $6,000 to $20,000 or more.

- How long does fermentation typically take in a 10bbl fermentation tank? The fermentation time can vary depending on the beer style and yeast strain, but it typically takes between 1 to 3 weeks.

- Can I use a 10bbl fermentation tank for other types of beverages? Yes, 10bbl fermentation tanks can be used for fermenting other beverages, such as cider or kombucha. However, you may need to make adjustments to the temperature and pressure controls to accommodate different fermentation requirements.

- Do I need any additional equipment to use a 10bbl fermentation tank? Besides the tank itself, you may need additional equipment, such as a glycol chiller, temperature control unit, and CIP system, to optimize the fermentation process.

- How do I maintain and clean a 10bbl fermentation tank? Regular cleaning and sanitation are crucial for maintaining your fermentation tank. Use a CIP system to circulate cleaning and sanitizing solutions through the tank and its components. Inspect the tank regularly for signs of wear or damage, and address any issues promptly.

End

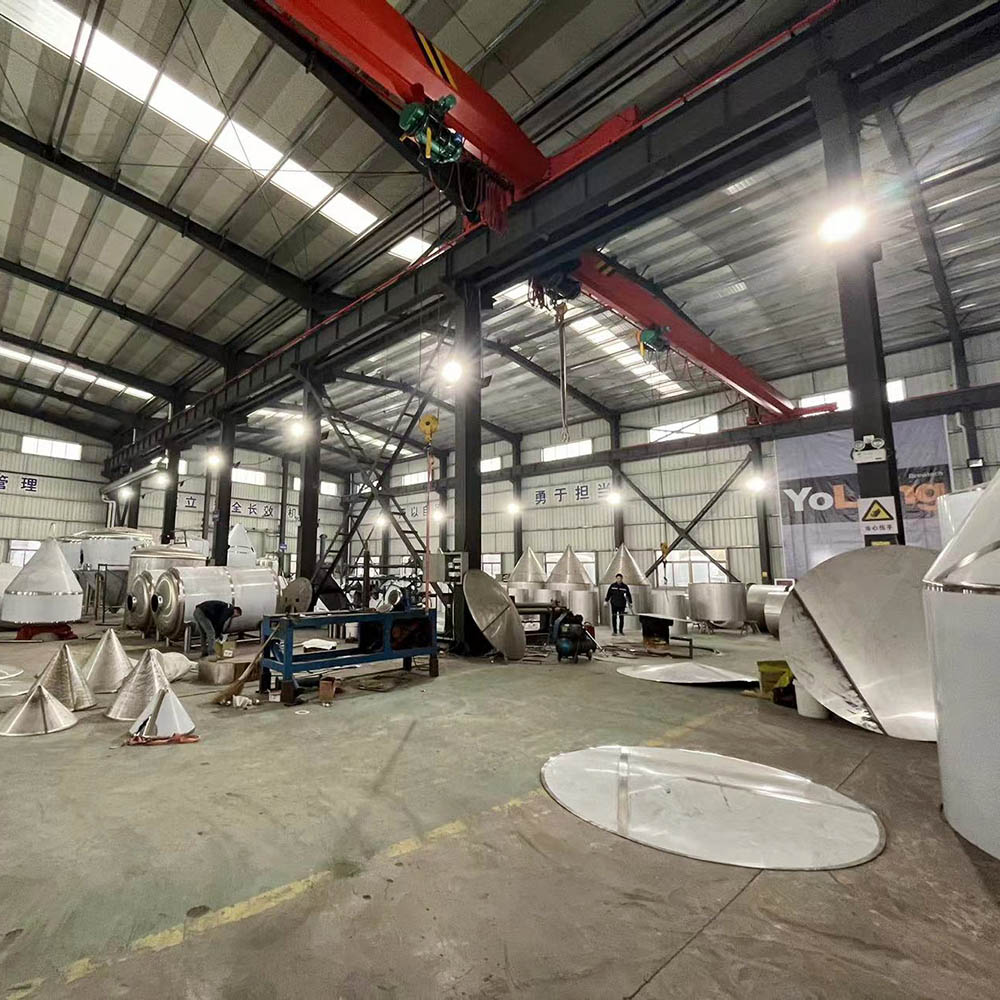

Thank you for reading this blog about 30bbl brewing systems. If you’re looking for a high-quality, durable, and easy-to-use 30bbl brewing system, we recommend the brewing equipment brand Yolong Brewtech. Yolong brewing equipment has a good reputation in the market, and their products’ quality and reliability have stood the test of time. To learn more, visit our product page and browse our brewing system products.