Two options for fermentation control system

With the vigorous development of the beverage industry, the production of beer is one of the largest technologically advanced industries. Currently, the correct operation of fermentation control systems has shifted to continuous monitoring.

An updated and modern fermentation control system that will improve product quality, reduce production costs and ensure safety. Today we will discuss this topic with YoLong’s fermentation control system.

If you are having questions about your brewing equipment and fermentation controls, please contact YoLong’s team of engineers to find out.

In terms of the beer fermentation control, there are mainly two options are used and considered:- Temp controllers cabinet_ & the PLC + HMI Combo_

Temp Control System:

The T-C control system will be a more cost-effective option than the PLC when there are not too many sets of FV & BBT in the brewery, Also easy for troubleshooting and once any malfunctions happened and no need to get the programmer to solve as any electrician will be able to get these done like replacing the temp controllers. Obviously, for the old-school brewers, the T-C cabinet looks also simple and gorgeous.

But in fact, the setting and detected data isn’t very visible on the T-C Control system, also before going into the following fermentation stages that need to be re-set manually, For different beer recipes that the fermentation status like temp & timing need to be recorded manually as well, In some sense that won’t be accurate than the PLC option.

PLC + HMI Combo system:

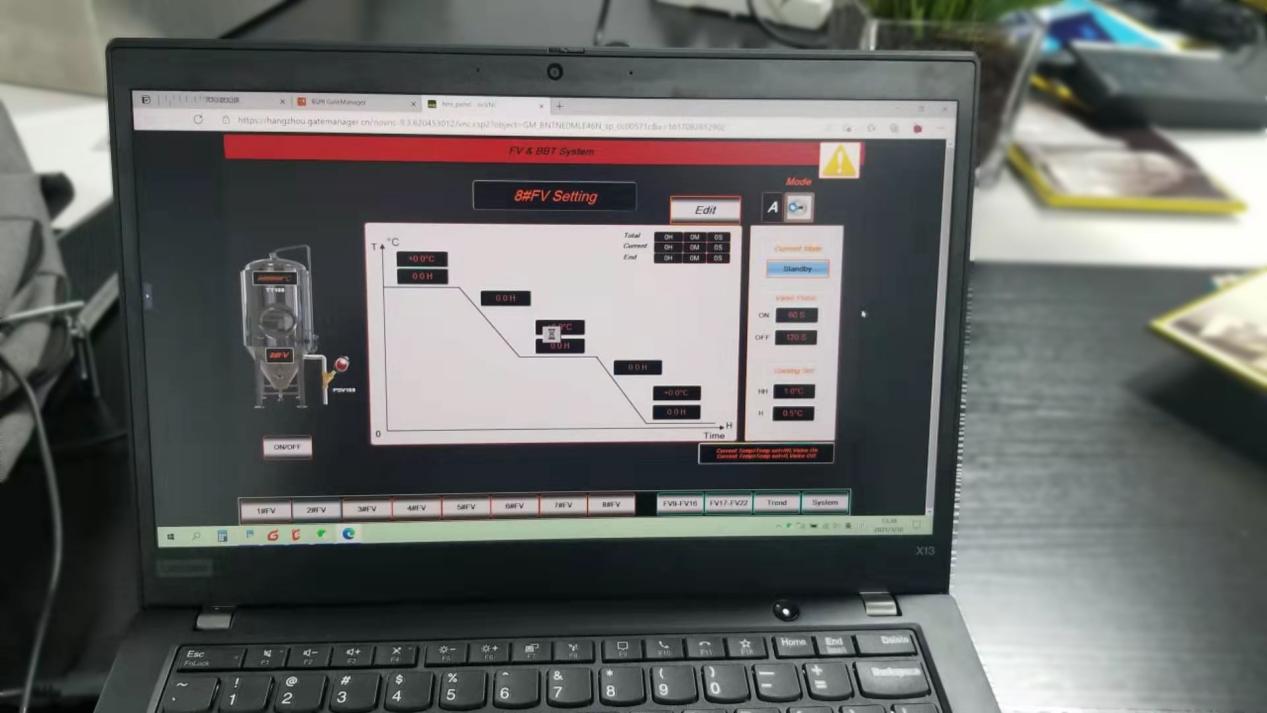

For every fermentation that will cost a few days/weeks and there’s no way for the brewer to keep on duty for 24h. Although for the small-scale brewery the PLC is an expensive option. However, it will provide more flexibility and reliability in the future.

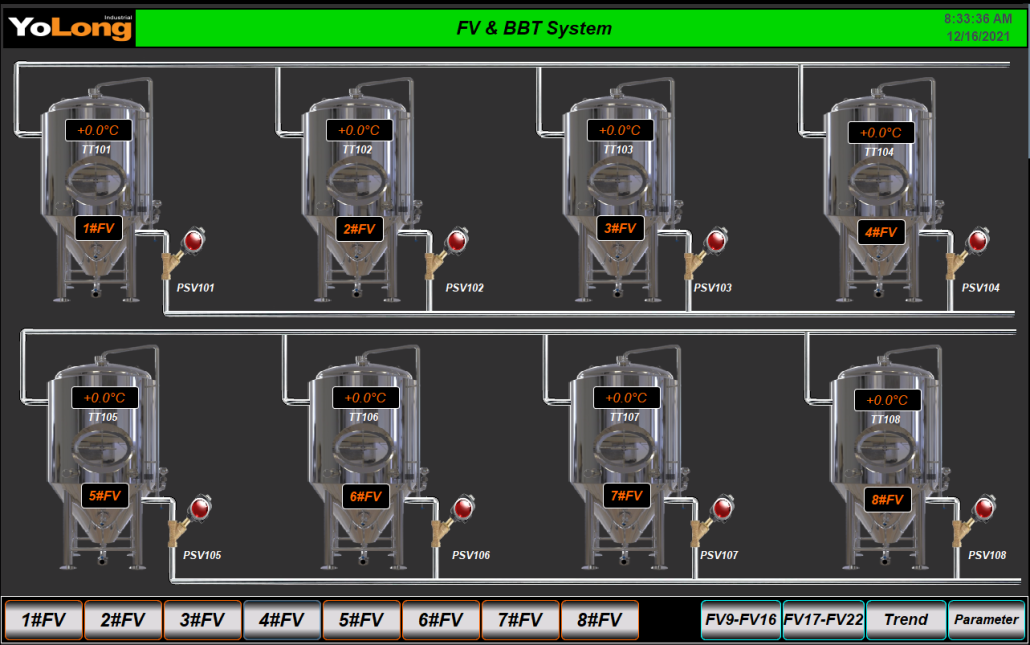

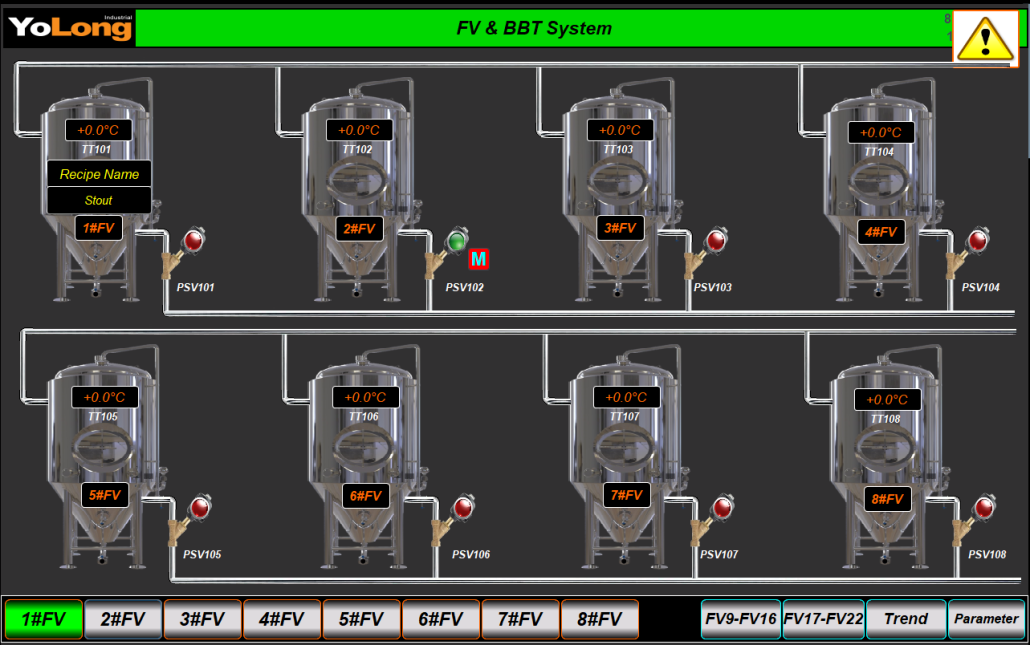

- For the brewery with plenty of cellar tanks, the PLC will be able to manage the tanks intensively and will also spend much more space than a T-C Cabinet, Also the fermentation status of each tank will be visible on the HMI.

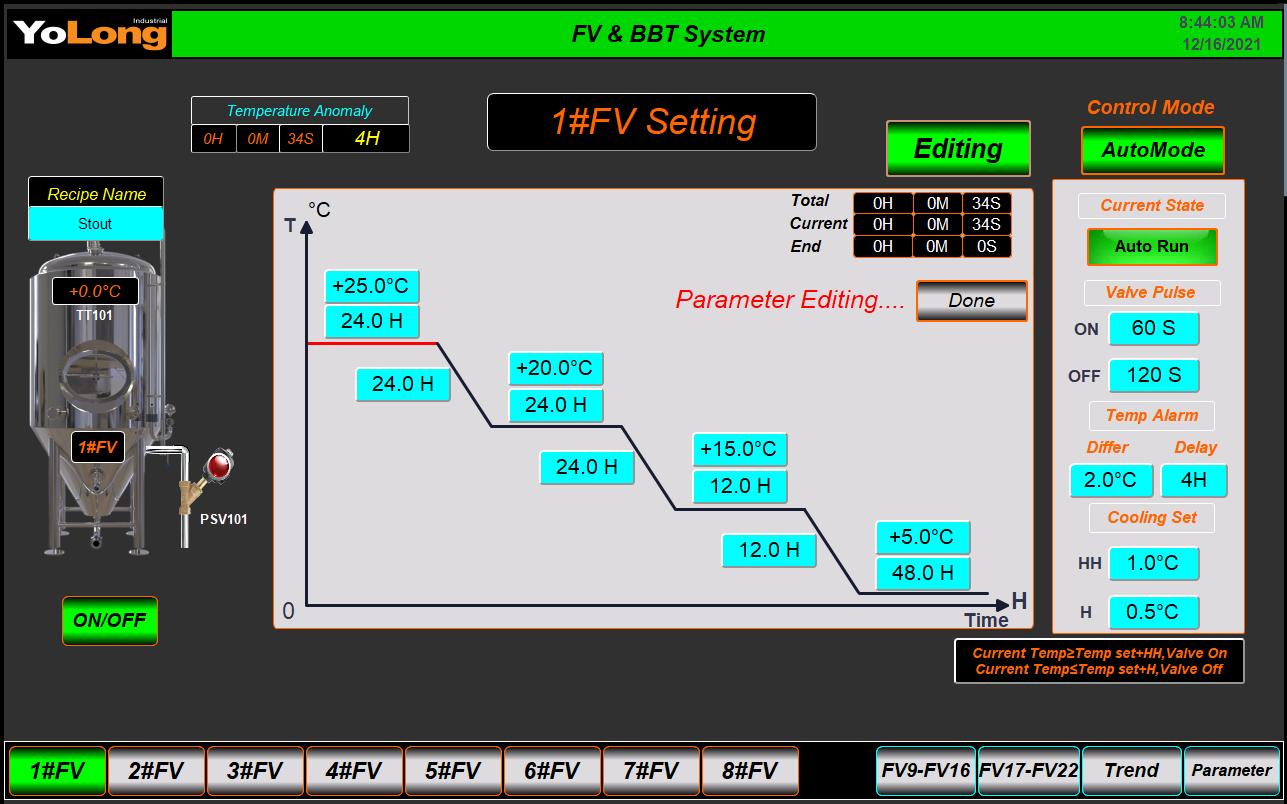

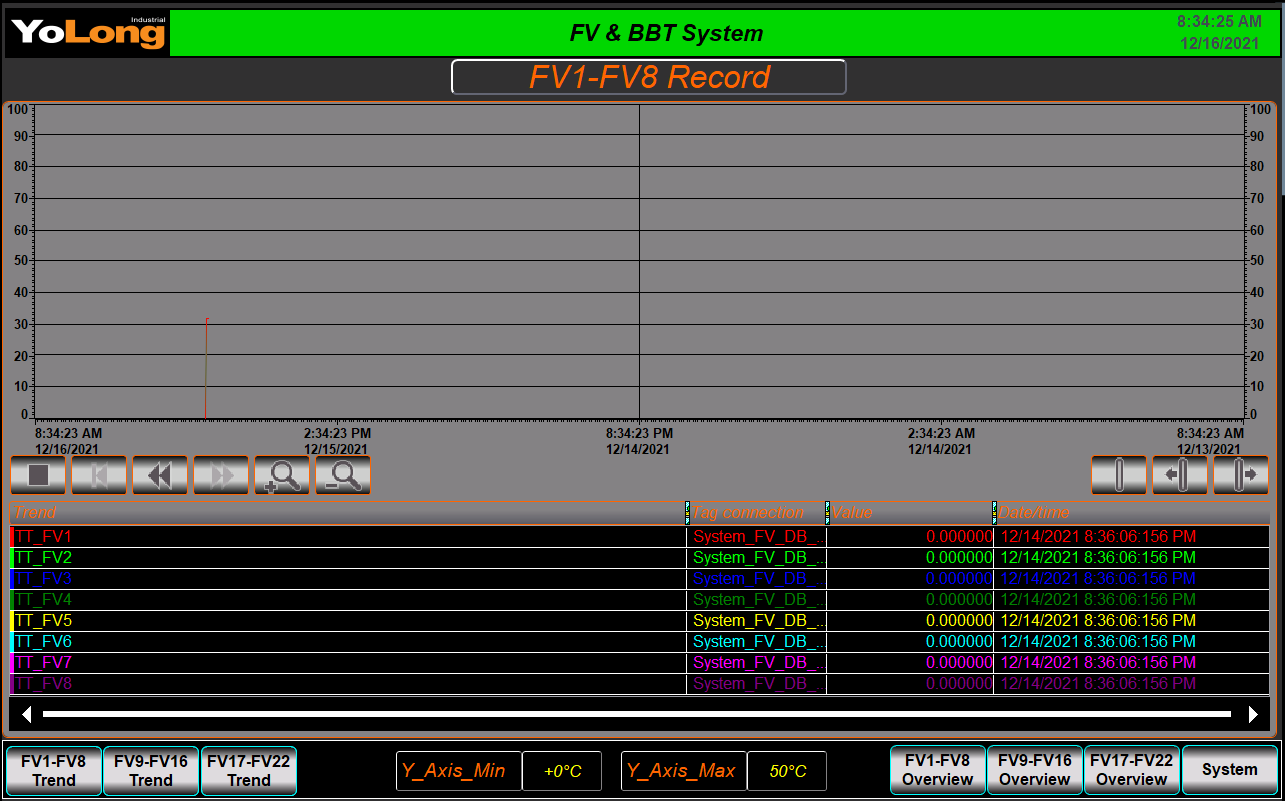

- Then for different brew recipes, the several fermentation steps could be set on the programming together, And the programming will be proceeding the different steps automatically based on the setting data of timing/temp, etc. More accuracy and flexibility than the first option.

- Alarming: By the programming, there are many abnormities that could be detected and alarmed, like abnormal fermentation temp, and abnormal glycol temp, so this option could avoid the issues happened caused by the temp sensor malfunctions, and promise the fermentation stage going smoothly.

- Any operation before getting done on the programming that the password required, so that also helps to reduce the possibility of the unprofessional person’s wrong operation.

- With HMI, For each tank, the fermentation curve is also very visible.

- In addition, if the budget is still considerable, we can add the site manager in the PLC combo, and then we can have remote access available which also means that we can supervise and control the fermentation on your phone anywhere.

BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to nano brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- Help expand your recipes.

- Learn how the Komhucha brewing system works

- Convince potential clients that you are on the right track.

- Be your most reliable “brewery problem solver” partner

- Make your commercial Kombucha brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

Additional FAQs for a Fermentation Control System

1) Which brewery size benefits most from a PLC + HMI fermentation control system?

- Generally, cellars with ≥6 tanks (FV/BBT) gain measurable ROI from PLC/HMI: automated step holds, alarms, trend data, and remote access reduce labor and variability. Under ~4 tanks, a temperature controller (T‑C) cabinet can be more cost‑effective.

2) Can a temperature controller cabinet still log data for compliance and QA?

- Yes. Add panel‑mounted chart recorders or pair T‑Cs with external data loggers (RTD/NTC to Bluetooth/Wi‑Fi gateways). Cloud sheets can capture temp setpoints, actuals, and alarm events without moving to full PLC.

3) What sensors are essential for robust fermentation control?

- Core: tank RTD/thermowell probes, glycol supply/return temperature, pressure/vacuum relief monitoring, and door/valve interlocks. Optional but valuable: specific gravity (inline/at‑line), dissolved oxygen on cold side, and foam conductivity sensors for blow‑off control.

4) How do I secure remote access to a PLC fermentation control system?

- Use a VPN or secure cellular gateway, role‑based access control (RBAC), strong passwords + MFA, and change default ports. Keep firmware patched, segregate brewery OT from office IT (VLANs), and log access events.

5) What’s the best practice for alarm management in fermentation?

- Define priority tiers (critical vs. informational), set deadbands/delays to avoid nuisance alarms, require acknowledgment, and implement escalation (SMS/email/app) with on‑call rotation. Review alarm history monthly to tune thresholds.

2025 Industry Trends: Fermentation Control Systems

- Edge analytics in the cellar: Affordable PLCs and IIoT modules provide real‑time trend analysis (attenuation rate, diacetyl rest triggers) without full MES.

- Standardized data models: More vendors supporting OPC UA/MQTT for interoperable logging to brewery LIMS/QA tools.

- Predictive control: Early adoption of model‑based control for diacetyl rest timing and crash initiation using SG/temperature slopes.

- Cybersecurity by default: Role‑based users, MFA, audit logs, and VPN gateways are becoming standard on new panels.

- Sustainability: Smarter glycol control (PID + valve modulation) and cellar zoning cut energy 10–20%.

2025 Benchmarks for Fermentation Control Performance

| Metric | Typical T‑C Cabinet | PLC + HMI System | Notes |

|---|---|---|---|

| Temp stability (FV, hold) | ±1.5–2.0°F (±0.8–1.1°C) | ±0.5–1.0°F (±0.3–0.6°C) | With jacket zoning, tuned PID |

| Alarm response time | Manual checks; minutes–hours | Seconds–minutes (push alerts) | Remote notifications standard |

| Data logging | Manual or add‑on logger | Native trending, cloud export | OPC UA/MQTT adoption growing |

| Labor time per batch (cellar ops) | Baseline | −10–20% | Due to automation of steps |

| Energy use (glycol) | Baseline | −8–15% | Modulated valves/VFD pumps |

| Typical cost (per 8–12 tanks) | $3k–$8k | $18k–$45k | Spec, I/O count, remote access |

Sources: Brewers Association QA/benchmarking 2024–2025; MBAA Technical Quarterly; ASBC methods; vendor specifications for PLC/HMI and IIoT modules; practitioner reports on ProBrewer/HomebrewTalk

Latest Research Cases

Case Study 1: PLC‑Driven Diacetyl Rest Optimization (2025)

Background: A 10‑tank cellar reported inconsistent diacetyl rest timing and occasional VDK failures on lagers.

Solution: Upgraded to PLC + HMI with dual RTDs (cone and shell) and programmed slope‑based rest triggers (temp rise initiated when attenuation rate decayed below threshold). Added remote alarms and audit logs.

Results: VDK failures dropped to zero over 20 consecutive batches; average tank days reduced by 0.6 days; energy use (glycol) decreased 9% via tighter setpoint control.

Case Study 2: Enhancing T‑C Cabinet with Cloud Logging (2024)

Background: Nano brewery with four FVs needed records for QA without investing in PLC.

Solution: Integrated panel data loggers and Wi‑Fi gateways on each T‑C, added SOPs for manual step changes with checklists and time‑stamped entries.

Results: Passed distributor QA audit; reduced manual temp overshoot incidents by 60%; created searchable fermentation history for recipe iterations.

Expert Opinions

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

“Real‑time temperature control and reliable data logging are foundational. They directly influence yeast performance, VDK reduction, and flavor stability.” - John Mallet, Brewing Operations Consultant; author of Malt: A Practical Guide

“Choose the control architecture that fits your tank count and growth path. Clean wiring, documented P&IDs, and validated alarms often deliver more value than flashy screens.” - Annie Johnson, Brewing Consultant; AHA Homebrewer of the Year

“For small cellars, augmenting temperature controllers with smart logging and checklists can bridge the gap—then scale to PLC when tank count or labor justifies it.”

Practical Tools and Resources

- Brewers Association – QA manuals, cellar best practices: https://www.brewersassociation.org

- Master Brewers Association of the Americas (MBAA) – Technical papers on fermentation control and glycol systems: https://www.mbaa.com

- American Society of Brewing Chemists (ASBC) – Methods for VDK (diacetyl), DO, pH: https://www.asbcnet.org

- OPC Foundation – OPC UA interoperability standards: https://opcfoundation.org

- NIST Cybersecurity Framework – Practical OT/IT security guidance: https://www.nist.gov/cyberframework

- ProBrewer – Fermentation control forums and case studies: https://www.probrewer.com

Sources and further reading:

- BA 2024–2025 QA/benchmarking briefs on cellar controls

- MBAA Technical Quarterly on PID tuning, jacket zoning, and alarm rationalization

- ASBC methods for diacetyl/VDK and fermentation monitoring

- Vendor whitepapers on PLC/HMI architectures, MQTT/OPC UA gateways, and secure remote access

- Practitioner threads on ProBrewer regarding cost/benefit of PLC vs T‑C solutions

Last updated: 2025-09-08

Changelog: Added 5 targeted FAQs; included a 2025 performance benchmarks table; provided two recent case studies; added expert viewpoints; compiled practical tools/resources with authoritative links.

Next review date & triggers: 2026-01-15 or earlier if BA/MBAA/ASBC guidance updates, cybersecurity standards change, or new PLC/T‑C cost-performance data impacts recommendations.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?