Beer Fermenters: Choosing, Using, and Maintaining

Overview of Beer Fermenters

Beer fermenters are the unsung heroes of the brewing process, playing a pivotal role in transforming wort into delicious, carbonated beer. Whether you’re a homebrewer experimenting in your garage or a commercial brewery churning out thousands of gallons daily, fermenters are where the magic happens. But what exactly makes a beer fermenter tick? What types are available, and how do you choose the right one? Let’s dive in and explore everything you need to know.

Types of Beer Fermenters

Beer fermenters come in various shapes, sizes, and materials, each tailored to meet specific brewing needs. Here are the main types:

1. Plastic Fermenters

Plastic fermenters are lightweight, affordable, and ideal for beginners. Typically made from food-grade polyethylene, they are easy to handle but prone to scratches, which can harbor bacteria if not cleaned properly.

2. Glass Carboys

Glass fermenters, or carboys, are popular for their non-porous nature and resistance to staining and odor retention. They provide a clear view of the fermentation process but are fragile and heavier than other options.

3. Stainless Steel Fermenters

Stainless steel fermenters are the gold standard for both home and commercial brewers. They are durable, easy to clean, and resistant to bacteria and oxidation. Their superior insulation makes them perfect for temperature-sensitive fermentation.

4. Conical Fermenters

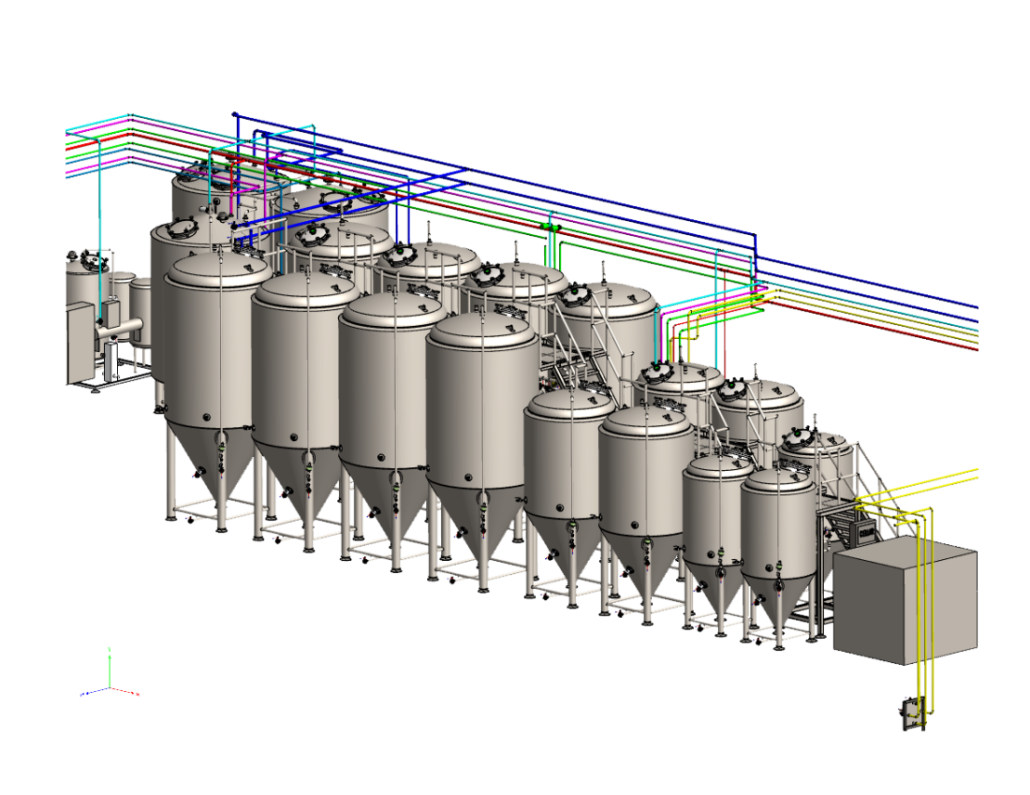

Conical fermenters have a cone-shaped bottom that allows easy removal of sediment and yeast. Available in various materials, these fermenters are ideal for secondary fermentation and large-scale production.

5. Unitanks

Unitanks combine fermentation and conditioning in one vessel. Used primarily by professional brewers, they streamline the brewing process and save space, though they can be pricey.

How to Choose a Suitable Beer Fermenter

Selecting the right fermenter depends on several factors. Here are key considerations to guide your decision:

- Batch Size: Homebrewers typically opt for smaller fermenters (5-10 gallons), while commercial setups require tanks holding hundreds or thousands of gallons.

- Material Preference: Stainless steel is ideal for durability and hygiene, while plastic and glass are budget-friendly alternatives.

- Temperature Control: Some fermenters come with built-in temperature regulation systems, crucial for precise brewing.

- Ease of Cleaning: Smooth surfaces like stainless steel or glass are easier to clean and sanitize.

- Budget: While stainless steel fermenters are superior, they’re costlier than plastic or glass options.

The Working Principle of Beer Fermenters

Fermenters are where yeast converts sugars in the wort into alcohol and carbon dioxide, a process called fermentation. Here’s how it works:

- Filling: The fermenter is filled with cooled wort, which contains dissolved oxygen for yeast health.

- Yeast Addition: Yeast is pitched into the wort to kickstart fermentation.

- Primary Fermentation: This stage lasts 3-10 days, during which yeast rapidly converts sugars into alcohol and produces heat and foam.

- Secondary Fermentation: Beer is transferred to a new vessel to mature, clarify, and develop flavors.

- Conditioning: Some fermenters allow carbonation during this stage, streamlining the process.

Maintenance and Cleaning of Beer Fermenters

| Step | Details |

|---|---|

| Pre-Cleaning | Rinse the fermenter immediately after use to prevent residue buildup. |

| Cleaning Agents | Use non-abrasive, brewery-approved cleaners to avoid scratches and damage. |

| Sanitization | Sanitize with no-rinse solutions before every use to prevent contamination. |

| Inspection | Check for scratches, dents, or cracks that can harbor bacteria. |

| Storage | Store in a clean, dry place to avoid mold or rust formation. |

Key Features to Consider When Choosing a Beer Fermenter

| Feature | Why It Matters |

|---|---|

| Material | Affects durability, insulation, and ease of cleaning. |

| Size | Must match your batch size to prevent overflow or underutilization. |

| Temperature Control | Ensures consistent fermentation, especially for lagers and ales. |

| Portability | Important for homebrewers who need to move fermenters often. |

| Ease of Maintenance | Reduces time spent cleaning and ensures a hygienic brewing environment. |

How Can Commercial Beer Fermenters Improve Production Efficiency?

Commercial beer fermenters are engineered for scalability and precision. Here’s how they make brewing more efficient:

- Larger Capacity: High-volume fermenters reduce the need for multiple small batches, saving time and resources.

- Integrated Systems: Features like automatic temperature control and CIP (Clean-In-Place) systems streamline operations.

- Durability: Made from industrial-grade stainless steel, these fermenters last longer, reducing replacement costs.

- Space Efficiency: Vertical designs maximize brewery floor space.

- Enhanced Quality Control: Consistent fermentation conditions lead to a uniform product, boosting customer satisfaction.

FAQ

| Question | Answer |

|---|---|

| What size fermenter should I use? | Match your fermenter to your batch size, allowing extra space for krausen. |

| How do I sanitize a fermenter? | Use a no-rinse sanitizer like Star San and ensure all surfaces are evenly coated. |

| Can I use plastic fermenters for long-term? | Yes, but avoid extended use as scratches can harbor bacteria over time. |

| Why is temperature control important? | It ensures yeast functions optimally, preventing off-flavors and stalled fermentations. |

| What is a conical fermenter used for? | To simplify sediment removal and secondary fermentation without transferring beer. |

Frequently Asked Questions (FAQ)

1) What pressure rating should modern Beer Fermenters have for commercial use?

- Most unitanks are certified 15–30 psi (103–207 kPa); larger regional tanks may be 30–45 psi. Verify PRV sizing, hydrostatic test certificates, and relief valve maintenance logs.

2) How much headspace is ideal in Beer Fermenters?

- Plan 15–25% headspace for standard ales, 20–30% for high-gravity or heavily dry-hopped beers to manage kräusen and hop creep CO2.

3) 304 vs. 316 stainless—what’s better for Beer Fermenters?

- 304 SS is the cost-effective standard. Choose 316 SS for sour/acidic programs, saline water, or aggressive CIP that increases chloride exposure.

4) Which features most improve flavor stability?

- Closed transfers, purgeable carb stones, low-DO racking arms, precise temperature control (±0.2–0.5°C), and pressure fermentation (spunding 8–15 psi) to retain volatile aroma.

5) How do I validate CIP effectiveness in Beer Fermenters?

- Confirm spray-ball coverage (riboflavin tests), track caustic concentration and temperature, verify contact times, and swab high-risk areas (racking port, manway gasket). Log every cycle.

2025 Industry Trends: Beer Fermenters

- Pressure fermentation mainstream: spunding and natural carbonation reduce tank time and oxygen exposure.

- Oxygen-avoidance by design: closed dry-hop dosers and purgeable ports standard on mid-tier unitanks.

- Smart cellars: integrated temp/pressure/level sensors feeding PLCs for predictive VDK rests and crash schedules.

- Sustainability: thicker insulation and optimized glycol loops lower energy/bbl by 10–20%; crash-cooling heat recovery gains adoption.

- Safety and compliance: insurers increasingly require fixed CO2 monitoring, PRV testing schedules, and confined-space SOPs.

Beer Fermenters Benchmarks and Costs (2025)

| Criterion | Home/Nano (≤3 bbl) | Small Craft (5–15 bbl) | Regional (30–120 bbl) | Notes/Sources |

|---|---|---|---|---|

| Preferred material | Stainless or PET conical | 304 SS jacketed conical | 304/316 SS jacketed unitank | BA/MBAA guidance |

| Pressure rating | 10–15 psi | 15–30 psi | 15–45 psi | Verify PRV & hydrotest |

| Temp stability | ±0.5–1.0°C | ±0.3–0.5°C | ±0.2–0.3°C | Multi-zone jackets + PU |

| DO control | Closed transfer optional | Closed hop doser standard | Packaged DO target <50 ppb | BA packaging |

| Typical unit cost (USD) | $200–$1,200 | $6,000–$22,000 per FV | $30,000–$120,000 per tank | Supplier catalogs |

References:

- Brewers Association: https://www.brewersassociation.org

- Master Brewers Association of the Americas (MBAA) Technical Quarterly: https://www.mbaa.com

- American Society of Brewing Chemists (ASBC) Methods: https://www.asbcnet.org

Latest Research Cases

Case Study 1: Pressure-Capable Unitanks Cut Oxygen and Tank Time (2025)

Background: A 10 bbl brewery observed aroma fade and high package DO using non-pressurizable fermenters.

Solution: Upgraded to jacketed, pressure-rated Beer Fermenters with spunding valves, purgeable carb stones, closed dry-hop doser, and fully closed transfers.

Results: Packaged DO dropped from 120–160 ppb to 30–45 ppb; average tank time reduced by 1.5 days; shelf-life sensory stability extended ~4 weeks.

Case Study 2: Predictive VDK Rest via Smart Fermenter Controls (2024)

Background: Regional producer (60–90 bbl FVs) had inconsistent diacetyl rest durations across lagers.

Solution: Added inline temp/pressure sensors and PLC logic triggering VDK rests based on fermentation rate and temperature profiles; recalibrated jackets to ±0.2°C stability.

Results: VDK rest time decreased 18–24 hours; off-flavor incidents down 35%; cellar energy intensity improved 6–8%.

Expert Opinions

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

Key viewpoint: “In hop-forward beers, pressure-capable, oxygen-tight Beer Fermenters plus closed transfers are as impactful as hop choice for aroma retention.” - Ashton Lewis, Brewing Scientist and MBAA contributor

Key viewpoint: “Sanitary welds, full CIP coverage, and proper racking arm geometry reduce labor and contamination risk—cheap tanks often cost more over time.” - Katie Wallace, Sustainability leader in craft brewing

Key viewpoint: “Insulated, jacketed Beer Fermenters paired with right-sized glycol systems deliver immediate utility savings and help meet tightening environmental standards.”

Practical Tools/Resources

- Brewers Association: cellar best practices, oxygen control, tank safety

https://www.brewersassociation.org - MBAA Technical Quarterly: fermenter design, CIP validation, pressure fermentation case studies

https://www.mbaa.com - ASBC Methods: DO/CO2 measurement, VDK analysis, fermentation monitoring

https://www.asbcnet.org - Yeast calculators and pitch rate tools

https://www.whitelabs.com | https://www.lallemandbrewing.com - Vendor spec libraries (pressure ratings, jacket zones, PRV sizing)

SS Brewtech, Spike Brewing, Alpha Brewing Ops, Lehui

SEO note: Internally link to “Beer Fermenters,” “pressure-capable unitanks,” “closed transfer systems,” and “glycol system sizing.”

Last updated: 2025-08-28

Changelog: Added 5 FAQs; 2025 trends with benchmark table and references; two recent case studies; expert viewpoints; and curated tools/resources focused on Beer Fermenters selection and operation

Next review date & triggers: 2026-02-01 or earlier if BA/MBAA publish new oxygen control guidance, supplier specs change, or pricing shifts impact fermenter selection ROI

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?