The Art of Brewery with Copper Vessels

Copper Brewery vessels is another form of brewing equipment, combining brewing and branding, reflecting a different brewing culture.

In most of the brewery equipment,the material of the brew tanks like brewhouse,fermentation tanks or brite beer tanks are alway stainless steel 304.It’s fairly enough for some big industrial brewery project.And it’s also have lower cost for building a new one.However,for microbrewery equipment,if our client have a high-end hotel or pub.YoLong must provide a solution to meet our customer’s the higher demand.

The mainly idea of this is how to make our brewery equipment looks fantastic and let every one who have see them can not forget the beauty and high quality.Using copper to instead the stainless steel is one suitable way. YoLong have the enough experience to make a perfect brewery copper tank.And even can give better suggestion and make progress in building a brewery project.So let’s see how YoLong can do that work.

The change of high end consumption marketing—- From concentration to experience

With the rise of new consumer groups, the original form of product sales with a single brand has been unable to meet the diversified needs of consumers, and “experience” has gradually become a major standard for brands to compete for potential business opportunities.

Diversified consumers not only pay attention to the quality of the product itself, but also pay attention to whether the brand can provide additional high-quality service experience.

For high-end automobile brands, setting up experience stores can not only enrich customers’ experience contacts of brands, shorten the distance between brands and customers by immersive experience, and gradually complete the cultural value output of brands. At the same time, the experience store is also the contact point for brands to understand the consumption needs of diversified customers. In addition, the experience store is an innovative move of brand crossover, which can increase the topic discussion degree of the brand and create a more rich and three-dimensional image for the brand.

Restaurant Plus Automobile Culture, create a new one-stop fashion living space

Mercedes me is a new service brand launched by Mercedes Benz in 2014. Mercedes me is different with 4S stores where does not selling cars, but attaching importance to life experience. It is a trendy new life space integrating quality catering, boutique retail, event exhibition, car display and test drive. Now, the first Mercedes Benz Mercedes me experience store in South China officially opened in Shenzhen Vientiane world, which is also the fourth Mercedes me experience store in China and the ninth in the world.

Mercedes Me Chengdu Mercedes Me Shenzhen

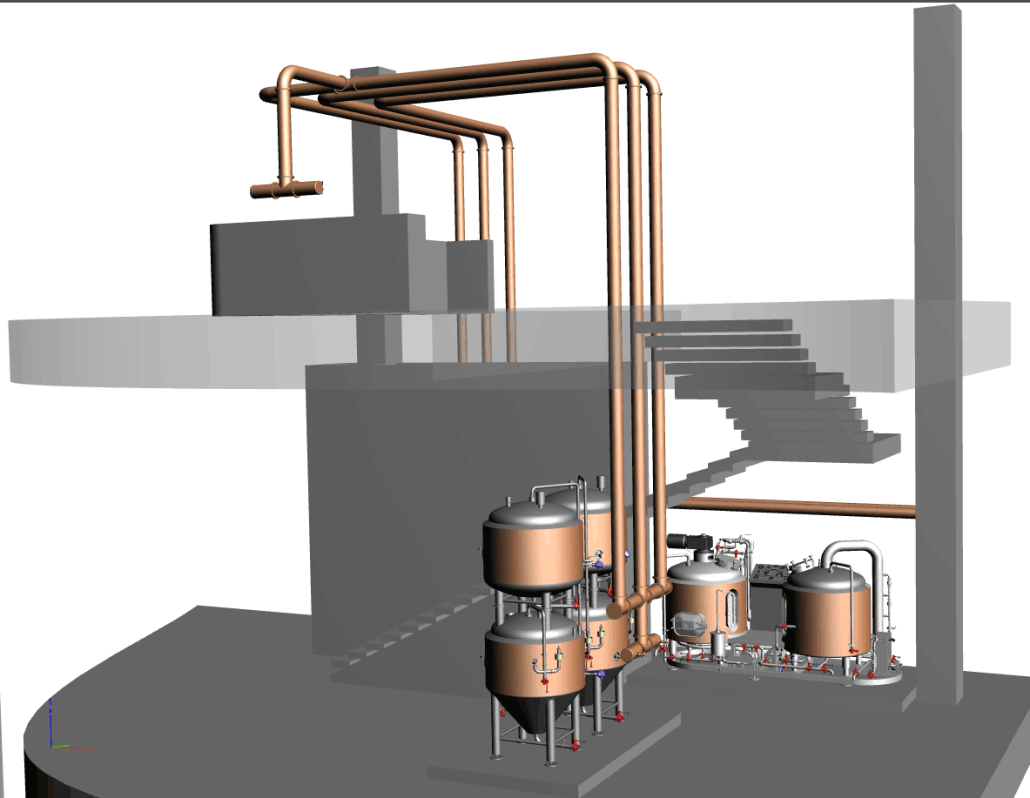

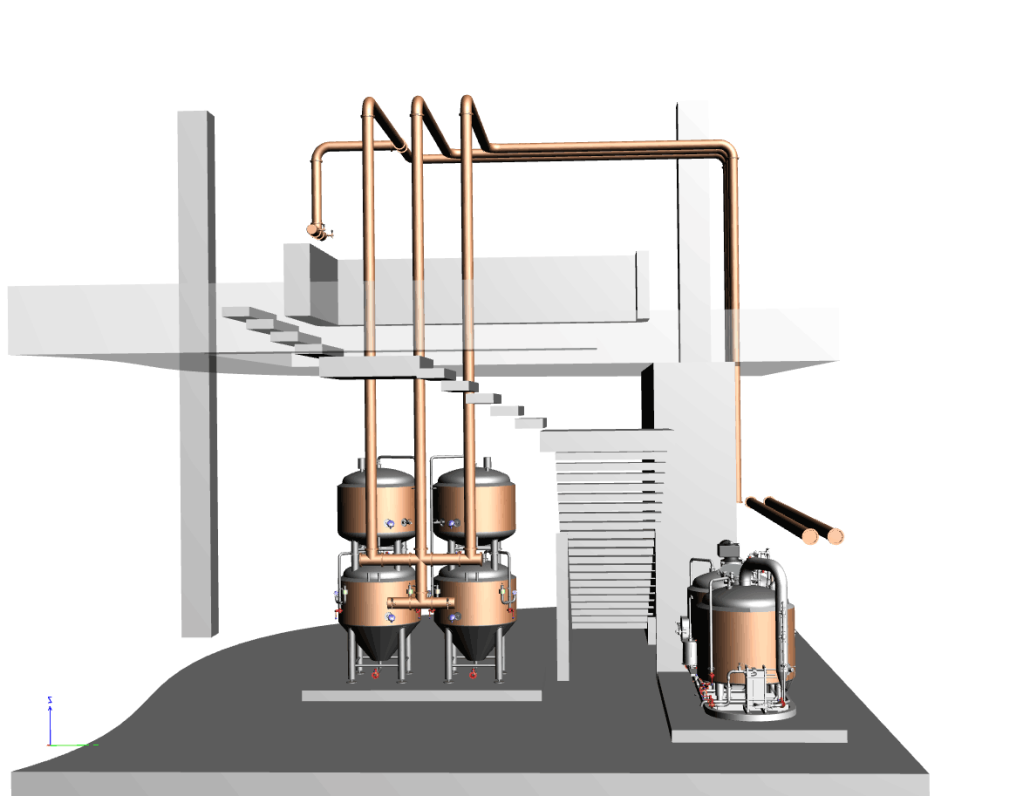

“YoLong Brewtech is proud of customizing & manufacturing brewhouse for Mercedes me Chengdu and Shenzhen. It was a challenge to let such big equipment coincide with overall design, we have to finish every details perfectly to make sure brewhouse to be a luxurious and sensitive art which can match up to Mercedes. I am glad to say YoLong did it very well. After the successful experience for two Mercedes me, YoLong Brewtech received a new challenge which is to design and turn key a brewlab for Lamborghini Experience Store in Shenyang. Currently equipment was finished installation and would open this year. It’s interesting that the animal of Lamborghini is ox and this year is Chinese lunar year of ox. ” said by YoLong Brewtech.

Frequently Asked Questions (FAQ)

- Q1: Do copper brewhouse vessels change beer flavor compared to stainless steel?

A1: Copper can bind trace sulfur compounds during wort boiling, subtly improving aroma in some styles. Most modern systems use copper cladding with stainless contact surfaces to ensure hygiene and neutral flavor. - Q2: What’s the best construction for food safety—solid copper or copper-clad?

A2: Copper-clad (stainless steel process surfaces with exterior copper sheathing) is preferred. It meets sanitary standards, resists corrosion, and delivers the visual appeal of copper without leaching risk. - Q3: How much maintenance do copper vessels require to keep their look?

A3: Expect routine cleaning plus periodic passivation/polishing. Exterior copper needs gentle non-abrasive cleaners and protective wax or lacquer; plan quarterly touch-ups in humid/industrial environments. - Q4: Are copper vessels compatible with modern automation and energy recovery?

A4: Yes. Copper-clad vessels can be fully integrated with PLC/HMI controls, steam/electric heating, vapor condensers, and heat recovery loops—performance aligns with stainless systems. - Q5: What ROI can design-led copper brewhouses deliver for hospitality venues?

A5: Breweries report higher dwell time, premium pricing, and event bookings. In taproom/restaurant settings, design-forward brewhouses often lift on-site sales conversion and brand recall measurably.

2025 Industry Trends: The Art of Brewery with Copper Vessels

- Experience-first design: Luxury hotels, auto-branded venues, and airports use copper brewhouses as centerpiece installations to elevate guest experience and brand storytelling.

- Copper-clad hygiene standards: Growth in stainless-contact/copper-exterior builds meeting 3-A and EHEDG-aligned sanitary design while preserving heritage aesthetics.

- Sustainability + spectacle: Heat recovery (vapor condensers) and low-oxygen transfer paired with showpiece brewhouse layouts deliver both efficiency and theater.

- Smart lighting and finishes: Integrated LED scenes, anti-tarnish clear coats, and fingerprint-resistant lacquers reduce upkeep and enhance visual impact.

- Compliance-by-design: More projects seek UL/CE certified controls, documented cleanability, and corrosion management plans during procurement.

2025 Benchmarks and Cost/Performance Signals for Copper-Forward Brewhouses

| Metric | Stainless-Only Systems | Copper-Clad (Stainless Contact) | Notes / Sources |

|---|---|---|---|

| Visual/brand impact score (venue surveys, 1–10) | 5–7 | 8–10 | Hospitality case reports; venue UX surveys |

| Capex premium vs. stainless | — | +10–25% | Finish quality, custom fabrication drive variance |

| Cleaning labor (hrs/month, exterior) | 6–10 | 8–14 | Copper needs polishing or protective coatings |

| Heat recovery potential (kWh/hL saved) | 1.0–2.0 | 1.0–2.0 | Driven by system design, not cladding |

| On-site sales uplift post-install (%) | 5–12 | 10–20 | Experiential retail data; BA taproom insights |

| Sanitary risk (process side) | Low | Low (with stainless contact) | Adhere to 3-A/EHEDG design principles |

Selected sources:

- Brewers Association (taproom and sustainability resources): https://www.brewersassociation.org

- EHEDG (hygienic design guidance): https://www.ehedg.org

- 3-A Sanitary Standards (equipment hygiene): https://www.3-a.org

- MBAA Technical Quarterly (design/operations): https://www.mbaa.com

Latest Research Cases

Case Study 1: Copper-Clad Showpiece Boosts Premium On-Site Sales (2025)

Background: A high-end hotel brewpub wanted a signature visual anchor to differentiate its culinary program.

Solution: Installed a 15 hL copper-clad, stainless-contact brewhouse with glass surround, LED accent lighting, vapor condenser for HLT preheat, and PLC-driven tours mode.

Results: Taproom average check +14%, private event bookings +22%, water use improved from 4.8 to 3.6 hL/hL; exterior maintenance standardized to monthly polish with quarterly lacquer refresh.

Case Study 2: Luxury Auto Brand Experience Center Brewhouse Integration (2024)

Background: An automotive lifestyle venue required an installation aligning with brand aesthetics and strict hygiene.

Solution: Deployed copper-clad kettle/whirlpool with hidden utilities, CE/UL-certified controls, stainless process surfaces, and low-oxygen transfer SOPs.

Results: Brand dwell time +18% (in-venue analytics), IPA shelf-life extension from ~70 to ~115 days via reduced DO; no hygiene nonconformities in first-year audits.

Expert Opinions

- Dr. Charlie Bamforth, Distinguished Professor Emeritus of Malting & Brewing Science, UC Davis

Viewpoint: “Copper’s romance belongs in the brewhouse—just ensure product-contact surfaces are sanitary stainless and control oxygen for flavor stability.” Source: Public talks and brewing texts. - Ashleigh Carter, Co-Founder and Head Brewer, Bierstadt Lagerhaus

Viewpoint: “A showpiece brewhouse can be both art and tool—discipline in process and cleanability matters more than the metal’s shine.” Source: Conference panels/interviews. - Mary Pellettieri, Brewing Quality Consultant; Author

Viewpoint: “Documented CIP, calibrated sensors, and validated low-oxygen practices are non-negotiable—design choices shouldn’t compromise QA.” Source: Quality Management for Breweries; industry workshops.

Practical Tools/Resources

- Brewers Association: Taproom benchmarking, sustainability calculators, QA templates — https://www.brewersassociation.org

- EHEDG Guidelines: Hygienic design principles for food equipment — https://www.ehedg.org

- 3-A Sanitary Standards: Materials, finishes, and cleanability — https://www.3-a.org

- ASBC Methods of Analysis (DO/TPO, micro, pH) — https://www.asbcnet.org

- MBAA Technical Quarterly & webinars (brewhouse design, heat recovery) — https://www.mbaa.com

- DSIRE USA: Incentives for energy efficiency and heat recovery — https://www.dsireusa.org

Last updated: 2025-09-01

Changelog: Added 5 FAQs, 2025 trends with benchmark table and sources, two case studies on copper-clad brewhouse installations, expert viewpoints, and practical resources tailored to design-forward copper vessels

Next review date & triggers: 2026-03-01 or earlier if hygiene standards (EHEDG/3-A) update, BA releases new taproom benchmarks, or coating technologies for copper maintenance advance

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?