10 Great Tips to Optimize Dry Hop Bouquet

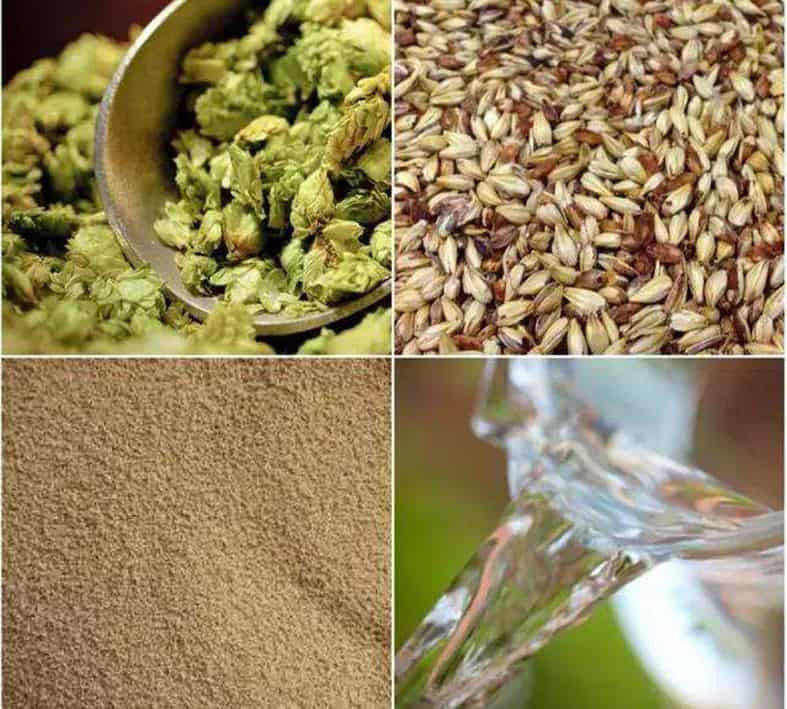

Longing for your IPA and the heady bouquet of pale ale?

Enjoy the sensation that your nose is full of it?

Want to make the alchemist’s lintopper dry drop in your own beer?

Here are 10 things that, if done, will add to your bouquet.

1. Use granulated hops

According to research by Peter Wolfe (Oregon state university) and Mitch Steele (Stone Brewing), hop-grain is the most widely used dry thrower in the United States.While some brewers are still debating whether grains are good or not, there’s no denying the fact that particle hops extract faster and better than dried ones.

2. Consider multiple varieties

Like salt and pepper, different varieties of hops should work together. Whether it’s Simcoe and Amarillo, Citra and Centennial, Chinook and Cascade, or Nelson Sauvin and Columbus, two or more hops can give your beer a better depth. In fact, you’ll find that you have to find a balance between multiple hops, or some of them will overwrite other features.

3. Use multistage dry throws

According to Steele, Vinnie Cilurzo (Russian river winery), Matt Brynildson (firestone walker winery) and Jamil Zainasheff (Heretic winery), multi-stage dry drop hops will add greater depth to your beer.

Raised to the scale of commercial production, the need for multistage dry drop is straightforward: the shape of the cylindrical fermentation tank results in very small areas of contact between hops and liquid at the bottom of the tank. Wolfe doesn’t believe the technology can be of much benefit to home-brewed beer, as many fermenters use flat pans. As far as I’m concerned, I’ve noticed some obvious differences between what I’m doing with first-level dry throws and what I’m doing with multiple-level dry throws.

4. Take advantage of higher temperatures

The higher the drying temperature, the better the aroma.In “For The Love of Hops,” author Stan Hieronymus reports on dry Hops temperatures at commercial breweries: Stone at 16.7 degrees, Lagunitas at 21.1 degrees, new Belgium at 12.2 degrees, and sierra Nevada at 20 degrees.

Even breweries, like Jack’s Abby, raise the temperature to 13 degrees during dry spells. For me, I find it easiest to dry drop hops at ambient fermentation temperatures (18.9-20 degrees).

5. Optimize soaking time

Many commercial breweries have the ability to awaken hops, keeping them suspended in the liquid by means of hops or torpedo-like equipment. According to Wolfe, unawakened hops particles will only reach 3/4 of the aroma intensity of awakened hops (a peak of 4 days).

6. In the main fermentation dry cast

Most breweries dry drop hops after the main fermentation to prevent the yeast from absorbing the hops flavor and passing the flavor to the yeast used in subsequent batches. Some breweries have publicly ignored this dogma, dry-throwing hops at the end of the main fermentation. Lagunitas, new Belgium, sierra Nevada and firestone walkers do some (all) of the dry throwing of hops before reaching the finishing point.

Some brewery likes this approach because it takes advantage of the interaction between yeast and hops, reducing the oxidation of hops with the beer itself due to still-active yeasts.

7. Minimize oxidation

As any experienced brewer knows, minimizing oxygen uptake after fermentation is critical. For dry throw hops beer, this is essential! No matter how good your technique, it is essential to introduce oxygen during the cupping process. Reducing the total number of mature containers (secondary fermenters, kegs and bottles) is an easy way to reduce oxygen uptake. A better approach is to use the pond to purify all your equipment before transferring.

8. Use post casting/cyclotron precipitation

The study by Van Havig of Rock Bottom revealed that the post-drop hops/cyclothem precipitation may be more effective than the dry drop in achieving a high level of hops aroma. First, his data showed that longer boiling followed by the addition of hops (cycloprecipitation) led to more hops flavor, aroma and perceived bitterness. Second, longer boiling resists more hops flavor than dry throwing alone, so beer flavors are best developed in a boiling pot.

9. Understand the law of diminishing returns

The aroma of dried hops does not increase exponentially with the addition of more hops. In fact, Having shows that brewers can reach a point of diminishing returns by dribbling hops.

Many commercial distilleries report dry throw efficiencies of between 0.25 and 1.5 ounces per gallon (0.5 to 3 pounds per barrel), such as Stone, Lagunitas and new Belgium, which average 0.5 ounces per gallon (lb/BBL).

It was a clear good start, but in fact I found it.1.5oz/gallon is the best standard for my American IPAs.

10. Use your experience well

Preliminary results showed that the Double IPAs used 0.78 ounces per gallon for 11 days, the IPA used 0.48 ounces per gallon for 9 days, and the black IPA averaged 0.4 ounces per gallon for 12 days.

With the above methods in place, you can create a delicious beer bouquet.

We are professional beer brewing equipment manufacturer from China. For more tips and ideas on how to get your dry hop bouquet even better contact our experts today. We’d love to assist you!

Additional FAQs to Optimize Dry Hop Bouquet

- Q: What contact time maximizes aroma without grassy flavors?

A: Most studies and pro practice suggest 48–96 hours at 14–20°C for pellets. Longer soaks increase polyphenol extraction and vegetal notes. Monitor daily and crash once peak aroma is reached. - Q: Is biotransformation from early dry hopping worth it?

A: Dry hopping near the end of primary (1–4°P from terminal) can enhance tropical and citrus notes via yeast–hop biotransformation. Keep oxygen out and limit CO2 blow-off losses by closing the system. - Q: Pellets vs. whole-cone for bouquet?

A: T90 pellets generally provide 10–30% higher oil utilization, faster extraction, and better tank hygiene. Whole-cone can add “fresh hop” nuance but needs more mass and headspace. - Q: How much should I dose to optimize dry hop bouquet in IPAs?

A: Common targets are 4–10 g/L (0.5–1.3 oz/gal) for IPA and 8–16 g/L (1.0–2.1 oz/gal) for DIPA. Returns diminish above ~12 g/L unless you manage oxygen and polyphenols meticulously. - Q: Does temperature matter during dry hop?

A: Yes. Warmer (16–20°C) accelerates extraction and highlights fruity volatiles; cooler (0–10°C) preserves delicate top notes and reduces polyphenols. A staged approach (warm 24–48 h, then cold 24–48 h) balances intensity and smoothness.

2025 Industry Trends to Optimize Dry Hop Bouquet

- Oxygen control is non-negotiable: widespread adoption of CO2-purged hop dosers and closed-loop dry hop tees, targeting package DO <50–100 ppb.

- Shorter, smarter contact: many breweries switch to 48–72 h contact with gentle recirculation to avoid grassy pickup.

- Flowable hop products: CO2 hop extracts and flowable pellets reduce beer loss, tank residue, and polyphenols while delivering consistent aroma.

- Biotransformation on purpose: yeast selection (e.g., high beta-lyase) and timed hop charges to unlock bound thiols and monoterpene alcohols.

- Data-driven hopping: inline aroma sensors and dense logging of temp, pressure, and DO to correlate process with sensory outcomes.

2025 Benchmark Data for Dry Hopping (commercial and advanced homebrew)

| Parameter | Typical Range | Outcome Impact |

|---|---|---|

| Dry hop rate (IPA/DIPA) | 4–10 g/L / 8–16 g/L | Higher rates increase aroma but raise polyphenols and beer loss |

| Contact time | 48–96 h | Peak aroma often at 72 h; extended time risks vegetal notes |

| Temperature | 14–20°C (stage 1), 0–4°C (stage 2) | Warm extraction + cold polish improves balance |

| Oxygen exposure (pre-package DO) | <50–100 ppb | Lower DO correlates with slower hop fade |

| Beer loss per 10 g/L pellets | 0.5–1.0% volume | Flowables reduce loss 20–40% |

| Recirculation | Gentle 20–40 min/day | Improves uniformity; avoid shear and foaming |

Sources: Brewers Association and MBAA Technical Quarterly best practices; manufacturer application notes (2024–2025); peer-reviewed hop chemistry overviews. Validate for your system and yeast strain.

Latest Research Cases

Case Study 1: Closed Dry Hop and Staged Temperature for Aroma Retention (2025)

- Background: A 30 hL brewery reported rapid hop fade and elevated vegetal notes after 7 days on hops at 18–20°C.

- Solution: Adopted CO2-purged hop doser, staged contact (24–36 h at 18°C then 48 h at 2°C), and gentle daily recirculation (25 min) with head pressure 0.7 bar to minimize stripping.

- Results: Package DO median dropped from 130 ppb to 58 ppb; sensory panel reported 35% higher tropical/citrus intensity at day 45; polyphenol astringency defects decreased notably.

Case Study 2: Flowable Extracts Reduce Loss and Improve Repeatability (2024)

- Background: High beer losses (≥8%) and variable aroma using 12 g/L T90 pellets in a DIPA.

- Solution: Replaced 30% of T90 dose with CO2 hop extract for bittering/part aroma, kept 8 g/L T90 for top note, and implemented 72 h contact at 16°C.

- Results: Beer loss reduced by 2.4 percentage points; IBU and aroma variance tightened; consumer testing showed equal or improved perceived hop intensity with smoother bitterness.

Sources: MBAA TQ case notes on closed hopping and extract utilization; Brewers Association Quality resources; supplier technical white papers on flowable hop products. Performance varies by yeast, hopping regime, and cellar design.

Expert Opinions

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

- Viewpoint: “Contact time and temperature govern extraction kinetics; manage oxygen and polyphenols to keep fruit-forward volatiles from fading.”

- Reference: OSU hop research publications and industry seminars

- Stan Hieronymus, Author, “For the Love of Hops”

- Viewpoint: “Purposeful timing—during active fermentation for biotransformation or post‑fermentation for purity—lets you design the bouquet, not chase it.”

- Reference: Book and articles on hop aroma practices

- Mary Pellettieri, Brewing Quality Consultant

- Viewpoint: “Closed processes and validated sanitation preserve hop aroma gains; uncontrolled oxygen will erase them.”

- Reference: Brewers Association Quality resources

Practical Tools and Resources

- Brewers Association Quality and Hops resources: https://www.brewersassociation.org/

- Master Brewers Association of the Americas (MBAA) Technical Quarterly: https://www.mbaa.com/

- Hop science and variety data: Yakima Chief Hops (https://www.yakimachief.com/), BarthHaas (https://www.barthhaas.com/)

- Recipe/process software with dry hop timing: Brewfather (https://brewfather.app/), BeerSmith (https://beersmith.com/)

- DO/CO2 measurement: Anton Paar (https://www.anton-paar.com/), Zahm & Nagel (https://zahmnagel.com/)

- Sensory training: DraughtLab (https://www.draughtlab.com/)

Last updated: 2025-09-04

Changelog: Added five targeted FAQs; provided 2025 trend insights with a benchmark table; included two recent case studies on closed/staged hopping and flowable extracts; added expert viewpoints; curated practical tools/resources with authoritative links.

Next review date & triggers: 2026-03-01 or earlier if new hop chemistry research, BA/MBAA guidelines, or hop product innovations change best practices for optimizing dry hop bouquet.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?