Mastering the Craft of microbrewery equipment

Introduction

In recent years, the craft beer industry has experienced a tremendous boom, leading to the rise of microbreweries. These small-scale breweries focus on producing limited quantities of high-quality craft beer, often with unique flavors and styles that cater to niche markets. To achieve such excellence in brewing, microbreweries heavily rely on specialized equipment designed to optimize the brewing process and ensure the consistent production of top-notch craft beer. In this article, we will explore the essential microbrewery equipment and the various factors that contribute to their success.

What is a Microbrewery?

Before diving into the equipment, let’s understand what a microbrewery is. A microbrewery is a small-scale brewery that typically produces beer in relatively small batches compared to large commercial breweries. These breweries often emphasize traditional brewing techniques, experimentation with flavors, and a strong focus on quality over quantity.

Advantages of Microbreweries

Microbreweries offer several advantages over larger commercial breweries. They allow for greater creativity and innovation in brewing, enabling the production of unique and artisanal craft beers. Additionally, microbreweries foster a sense of community, often becoming local gathering spots and contributing to the cultural fabric of their regions.

Essential Microbrewery Equipment

To produce exceptional craft beer, microbreweries require a range of specialized equipment. Let’s explore some of the essential items in their equipment arsenal:

Brewing Kettles

Brewing kettles, also known as brew kettles or boiling kettles, are large vessels used to boil the wort during the brewing process. They come in various sizes and are typically made of stainless steel, copper, or other durable materials.

Fermentation Tanks

Fermentation tanks are crucial for the fermentation process, where yeast converts sugars into alcohol and carbon dioxide. These tanks are designed to maintain precise temperature and pressure conditions to ensure optimal fermentation.

Mash Tuns

Mash tuns are vessels used for the mashing process, where milled grains are mixed with water to extract fermentable sugars. This is a critical step in beer production that influences the beer’s flavor and body.

Cooling Systems

Cooling systems are essential to control the temperature of the brewing process, especially during wort cooling and fermentation. They help maintain consistency in the beer’s quality and prevent unwanted off-flavors.

Cleaning and Sanitization Equipment

Maintaining a hygienic brewing environment is vital to producing high-quality beer. Cleaning and sanitization equipment, such as keg washers and CIP (Clean-In-Place) systems, ensure that all brewing equipment remains free from contaminants.

Quality Control and Testing Devices

To maintain consistent quality, microbreweries rely on various testing devices to monitor and analyze the brewing process.

Hydrometers

Hydrometers are used to measure the specific gravity of wort and beer, providing information about the fermentation progress and alcohol content.

Refractometers

Refractometers are another tool to measure the sugar content in the wort and track the fermentation progress.

pH Meters

pH meters help monitor the acidity of the beer, which impacts its flavor and stability.

Beer Filtration Systems

Beer filtration is crucial to achieve clarity and remove any unwanted particles. Microbreweries use various filtration systems, such as plate filters or diatomaceous earth filters, to achieve the desired beer clarity.

Packaging Equipment

Once the craft beer is brewed and ready for distribution, microbreweries require specialized equipment for packaging.

Bottling Machines

Bottling machines are used to fill beer into bottles and cap them efficiently. These machines are available in various sizes and capacities to meet the specific production needs of microbreweries.

Canning Machines

Canning has become increasingly popular in the craft beer industry due to its portability and ability to preserve beer quality. Canning machines help seal beer into cans, protecting it from light and oxygen.

Kegging Systems

For bars, restaurants, and venues that serve craft beer on tap, kegging systems are essential. These systems allow microbreweries to package their beer in kegs, ensuring fresh and flavorful beer reaches consumers.

Microbrewery Automation and Software

To streamline operations and maintain consistency, many microbreweries incorporate automation and software solutions.

Automated brewing systems can control temperature, timing, and other variables, optimizing the brewing process and reducing manual labor.

Brewery management software helps with inventory tracking, recipe management, sales analysis, and more, providing valuable insights to make informed business decisions.

Creating a Microbrewery Layout

Designing a well-organized microbrewery layout is crucial for smooth operations and safety.

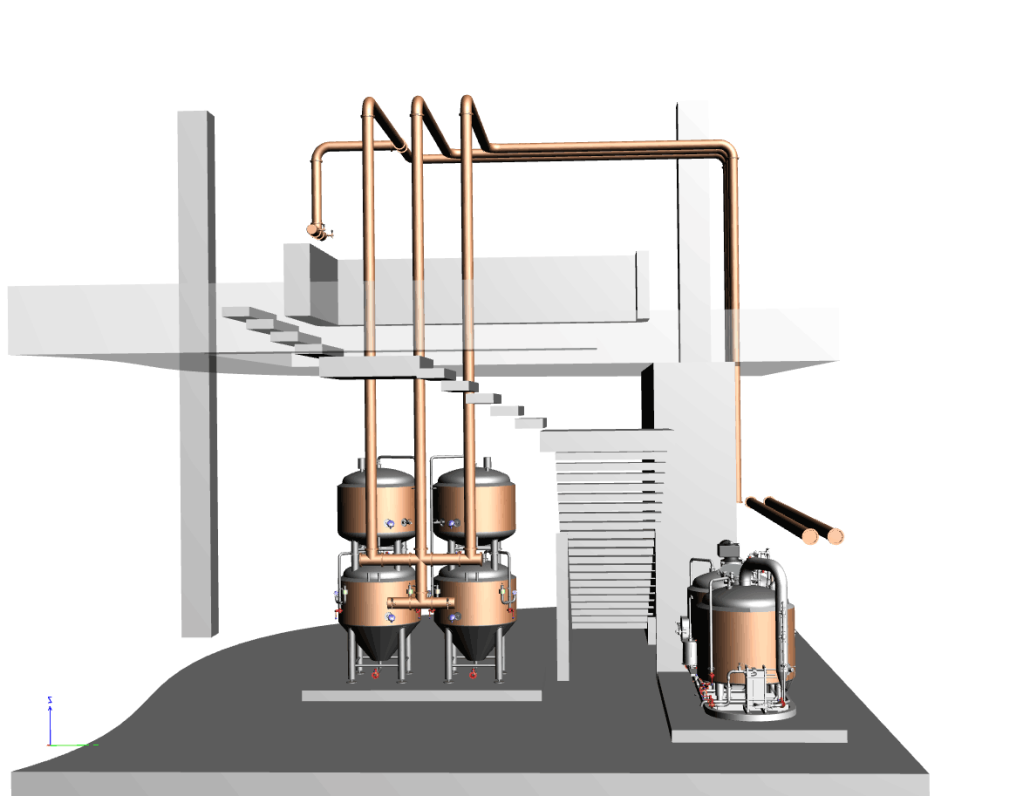

Brew House Design

The brew house is the heart of the microbrewery. Careful planning is required to arrange brewing kettles, mash tuns, and fermentation tanks in a way that maximizes efficiency and workflow.

Cellar Design

The cellar houses the fermentation and conditioning tanks. Proper placement and organization of these tanks are essential for maintaining ideal brewing conditions.

Tasting Room Design

For microbreweries with tasting rooms, creating an inviting and comfortable space for customers is vital. The layout should encourage socializing and provide an opportunity to showcase the brewery’s unique atmosphere.

Environmental Considerations

Microbreweries are increasingly conscious of their environmental impact. Implementing eco-friendly practices can benefit both the planet and the brewery’s reputation.

Water Efficiency

Water is a significant resource in brewing, and microbreweries can adopt water-saving technologies and practices to minimize waste.

Energy Efficiency

Optimizing energy usage not only reduces costs but also helps reduce the brewery’s carbon footprint. Investing in energy-efficient equipment and processes is a win-win for the environment and the bottom line.

Waste Management

Proper waste management, including recycling and composting, can significantly reduce the brewery’s environmental impact.

Microbrewery Safety Measures

Safety is of utmost importance in any industrial setting, and microbreweries are no exception. Implementing safety measures is essential to protect employees and ensure smooth operations.

11.1 Personal Protective Equipment (PPE)

All brewery staff should be equipped with appropriate PPE, such as gloves, safety goggles, and protective clothing, to prevent accidents and injuries.

Hazard Analysis and Critical Control Points (HACCP)

Implementing HACCP principles helps identify potential hazards in the brewing process and develop control measures to mitigate risks.

Emergency Response Plans

Microbreweries should have clear and well-communicated emergency response plans in place to address accidents, fires, or other unforeseen events.

Sourcing Quality Ingredients

To brew exceptional craft beer, microbreweries must carefully source high-quality ingredients.

Malt

Malt, typically made from barley, is the primary source of fermentable sugars in beer. Choosing the right malt varieties can significantly impact the beer’s flavor profile.

Hops

Hops contribute to beer’s bitterness, aroma, and flavor. Microbreweries often experiment with different hop varieties to create unique and distinct brews.

Yeast

Yeast is responsible for fermentation, and different yeast strains can produce various beer styles and flavors.

Marketing and Branding

Creating a strong brand identity is essential for microbreweries to stand out in a competitive market.

Creating a Brand Identity

Developing a unique and memorable brand identity helps consumers recognize and connect with the brewery.

Packaging Design

Attractive and eye-catching packaging can significantly influence consumer purchasing decisions.

Promotional Strategies

Microbreweries can engage with their community through events, social media, and collaborations to increase brand awareness and loyalty.

Microbrewery Maintenance

Regular maintenance of brewing equipment ensures consistent beer quality and extends the equipment’s lifespan.

Regular Equipment Inspections

Scheduled inspections help identify potential issues early and prevent costly breakdowns.

Cleaning and Sanitization Protocols

Maintaining a strict cleaning and sanitization routine is vital to prevent contamination and off-flavors in the beer.

Challenges and Solutions for Microbreweries

Microbreweries face various challenges in the competitive craft beer market.

Competition in the Craft Beer Market

Standing out among the numerous craft breweries requires unique offerings, branding, and marketing strategies.

Distribution and Sales

Finding distribution channels and effectively marketing the beer to retailers and consumers can be challenging for microbreweries.

Changing Consumer Preferences

Keeping up with evolving consumer tastes and trends demands flexibility and innovation.

Conclusion

Microbreweries play a significant role in the craft beer industry, offering a diverse range of flavorful and unique brews. Equipped with essential microbrewery equipment and armed with a passion for brewing, these small-scale breweries continue to win the hearts of beer enthusiasts worldwide. By focusing on quality, sustainability, and creativity, microbreweries will undoubtedly remain a vibrant and integral part of the beer culture for years to come.

FAQs

- What is the difference between a microbrewery and a macrobrewery?Microbreweries are small-scale breweries that produce limited quantities of craft beer, focusing on quality and experimentation. Macrobreweries are large commercial breweries that produce mass quantities of mainstream beer.

- What are the advantages of craft beer from microbreweries?Craft beer from microbreweries often offers unique flavors, artisanal quality, and a closer connection to the local community.

- What equipment is essential for a microbrewery startup?Essential equipment includes brewing kettles, fermentation tanks, mash tuns, cooling systems, and quality control devices.

- Are microbreweries environmentally friendly?Many microbreweries prioritize environmental sustainability through water and energy efficiency, waste management, and eco-friendly practices.

- How can microbreweries compete in a saturated market?Microbreweries can differentiate themselves through innovative beer styles, effective branding, and engaging with their local community.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?