How to make kombucha tea?

Kombucha is a delicious fermented beverage that, like beer, is fermented to achieve its final taste, but it is also very different from beer.

Have you ever wondered how to make kombucha? Today we will answer this question from the perspective of a kombucha brewer through the kombucha recipe and brewing process. If you are interested in kombucha brewing or looking for professional kombucha brewing equipment, you can contact YoLong engineer team for help.

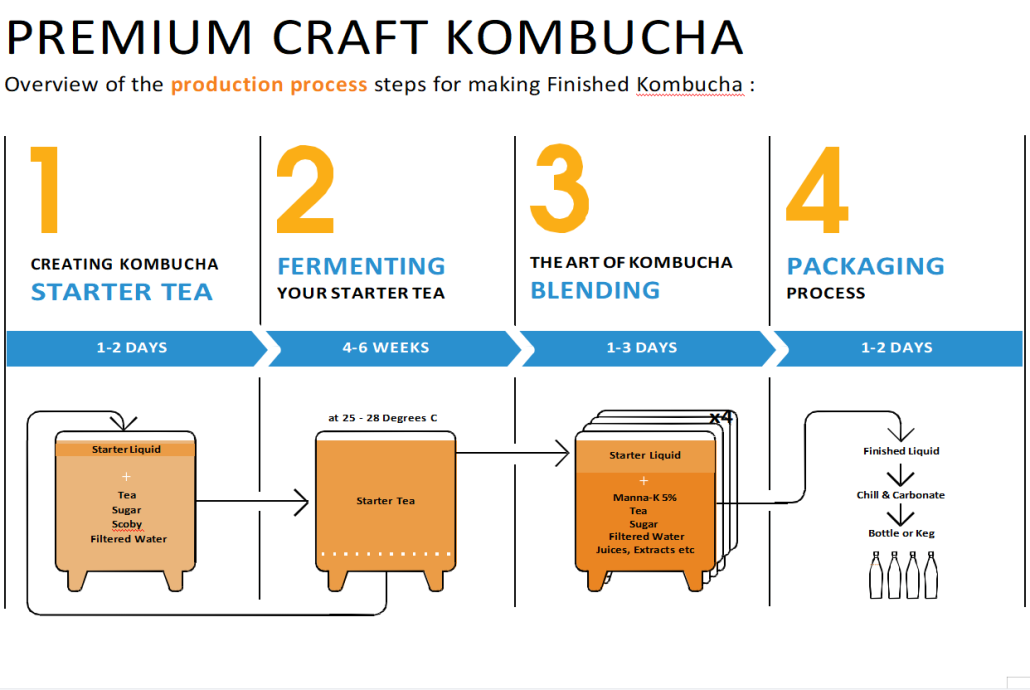

PREMIUM CRAFT KOMBUCHA

Overview of the production process steps for making Finished Kombucha :

- Creating Kombucha Starter Tea

Step process: Starter liquid + tea, sugar, SCOBY, filtered water

Process time: 1–2 days - Fermenting Your Starter Tea

Step process: Fermentation of starter tea at 25–28°C

Process time: 4–6 weeks - The Art of Kombucha: Blending

Step process: Starter liquid + Manna-K (5%) + tea, sugar, filtered water, juices, extracts, etc.

Process time: 1–3 days - Kombucha Packaging Process

Step process: Finished liquid → chill & carbonate → bottle or keg

Process time: 1–2 days

RECIPE

Brewing Starter Tea is an essential element if creating our Premium Craft Kombucha Recipe. This young & lively Starter Tea brings in a fresh yeast profile to your finished product which can be really fantastic.

Recipe for 1000 Litres of Starter Tea :

- 10 kg of Sencha Green Tea (goal: 10 g/L)

- 250 Litres of Hot Water forInfusion

- 60 kg of Organic Sugar (goal: 6 – 6.5 Brix or 60g/L)

- Water added in at the end, to reach a total volume of 900L

- 100 Litres of Starter Tea Liquid (goal: 10% of the totalvolume)

- Optionally 1% SCOBY

Notice:

Starter is very high in yeast, bacteria & alcohol. This combination is great for tasty home brews but not ideal for commercial kombucha at scale. This is why we use Starter Tea in combination with Manna-K.

Tips:

- Do not overfill the tea bag, give the leaves some space for a better infusion. Consider the leaves will expand by 10 times their dry volume.

- Use bag-cut tea leaves for an efficient infusion.

- We use a standard kombucha starter with 2.85 – 3.15 pH.

- Use a recipe sheet to keep track of what you are doing, and to track changes. Most importantly, log your pH and Brix values to compare and improve your recipes as they evolve.

This production method is designed for those who own & operate their own brewery. YoLong can provide Kombucha Brewing Equipment: Design, Fabricate, Install.

Free design, consultation

YoLong Brewtech has been facilitating the establishment and extension of breweries all over the world for over 15 years. We consider YoLong professional kombucha brewery equipment to be representative of our many years of industry experience and specialist knowledge in engineering the finest craft beer systems.

YoLong Kombucha Brewery Features:

- Energy efficient

- Easy to operate

- Minimal maintenance required – even over extended period

- Accessible deck platform height with ergonomic surface

- Easy installation on skids

- Adapts to expansion with modular components

- 1 or 2 vessel systems available

- Choice of production capacities (according to size of premises)

- Agitation mixer optional

PROCESSES

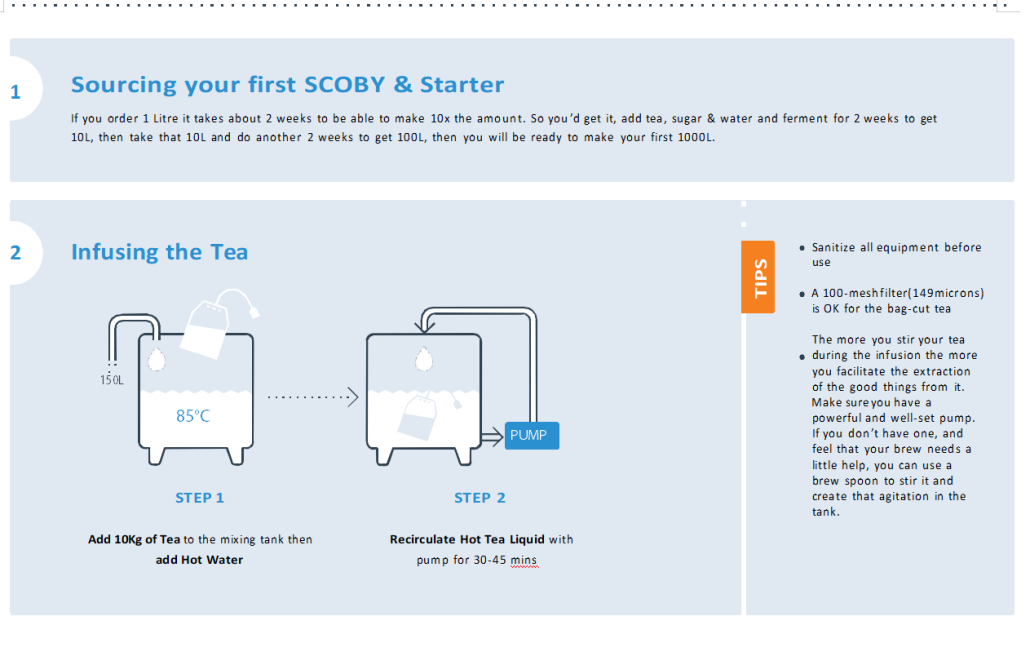

1:Sourcing your first SCOBY & Starter

If you order 1 Litre it takes about 2 weeks to be able to make 10x the amount. So you’d get it, add tea, sugar & water and ferment for 2 weeks to get 10L, then take that 10L and do another 2 weeks to get 100L, then you will be ready to make your first 1000L.

2:Infusing the Tea

Step1: Add10Kg of Tea to the mixing tank ,then add 150L 85℃ Hot Water .

Step2: Recirculate Hot Tea Liquid with pump for 30-45 min.

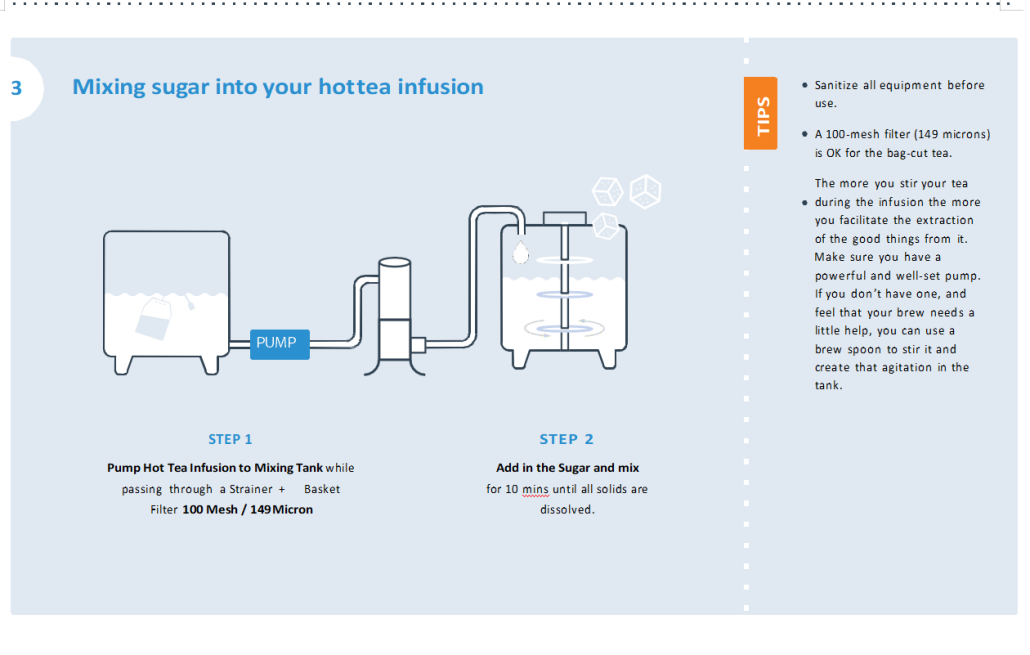

3:Mixing sugar into your hot tea infusion

Step1: Pump Hot Tea Infusion to Mixing Tank while passing through a Strainer + Basket Filter 100 Mesh/149 Micron.

Step2: Add in the Sugar and mix for 10 mins until all solids are dissolved.

TIPS:

1:Sanitize all equipment before use.

2:A 100-mesh filter (149 microns) is OK for the bag-cut tea.

3:The more you stir your tea during the infusion the more you facilitate the extraction of the good things from it. Make sure you have a powerful and well-set pump. If you don’t have one, and feel that your brew needs a little help, you can use a brew spoon to stir it and create that agitation in the tank.

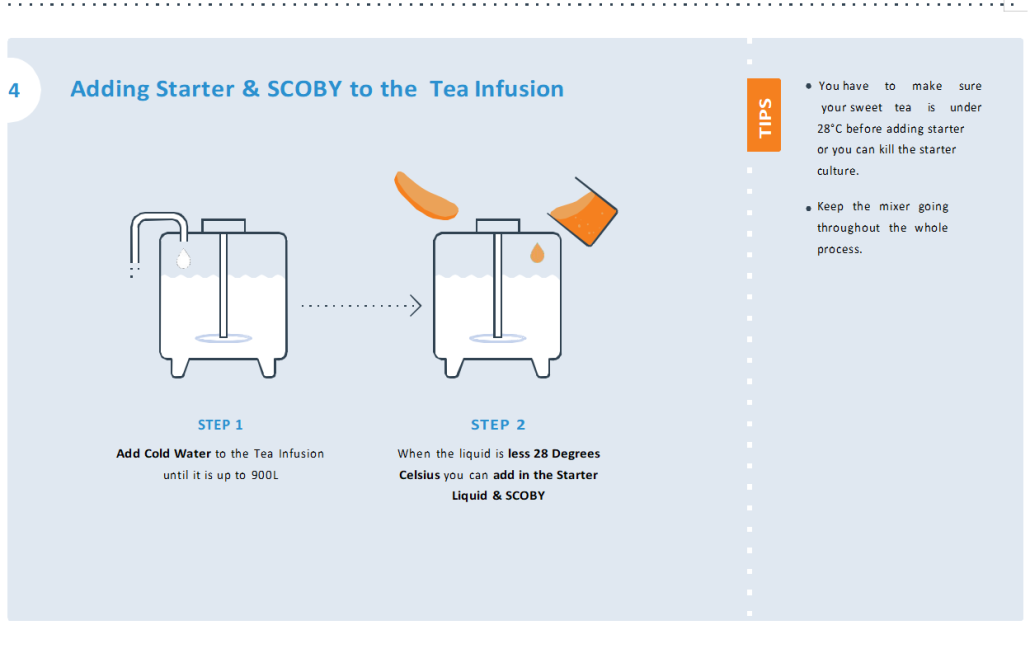

4:Adding Starter & SCOBY to the Tea Infusion

Step1: Add Cold Water to the Tea Infusion until it is up to 900L.

Step2: When the liquid is less 28 Degrees Celsius you can add in the Starter Liquid & SCOBY.

TIPS:

1:You have to make sure your sweet tea is under 28°C before adding starter or you can kill the starter culture.

2:Keep the mixer going throughout the whole process.

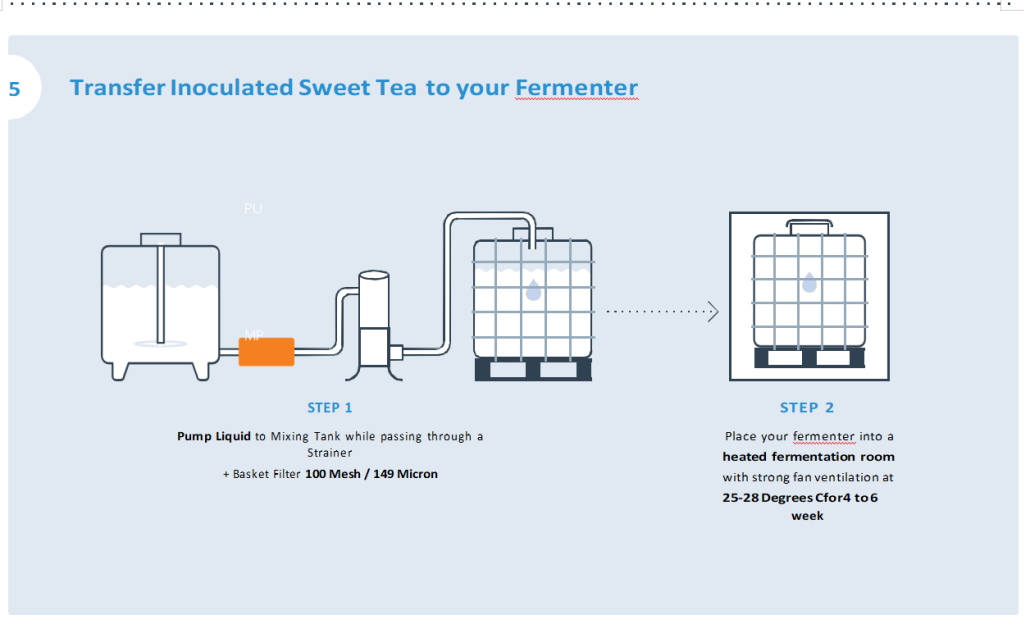

5:Transfer Inoculated Sweet Tea to your Fermenter

Step1: Pump Liquid to Mixing Tank while passing through a Strainer + Basket Filter 100 Mesh / 149 Micron.

Step2: Place your fermenter into a heated fermentation room with strong fan ventilation at 25-28 ℃ for 4 to 6 weeks.

6: Blending and Packaging

KOMBUCHA BREWERY BREWING CONSULTING

If you are not a professional brewer and are considering making the transition from home brewing to your own Kombucha brewery, it is a good idea to find a professional brewery consultant to help you through the first 30-90 days.

The Brewery Consultant will:

- Help expand your recipes.

- Learn how the Komhucha brewing system works

- Convince potential clients that you are on the right track.

- Be your most reliable “brewery problem solver” partner

- Make your commercial Kombucha brewery a reality in the near future

if you want to start your own brewing business. My company YoLong has been working on microbrewery & beverage projects since 2004, we can give you any assistance from 0 to turnkey. Check out the professional brewing consulting services we offer.

Frequently Asked Questions (FAQ)

1) What tea and sugar specs work best for kombucha tea at scale?

- Use bag-cut green or black tea (8–12 g/L) and cane sugar at 55–70 g/L initial Brix. Keep water low in chlorine/chloramine; activated carbon or Campden pre-treatment helps.

2) What is the ideal fermentation temperature and pH range?

- Primary fermentation: 25–28°C with vigorous airflow. Target starting pH 2.8–3.2 (with starter) and keep pH above 2.5 to protect SCOBY. Finished kombucha typically lands at pH 2.6–3.4.

3) How much starter tea should I add?

- 8–15% by volume is common. Your recipe uses 10% starter plus optional 1% SCOBY. Ensure sweet tea is ≤28°C before inoculation.

4) How do I control alcohol levels in kombucha tea?

- Maintain 25–28°C, adequate nutrients, and strong oxygen transfer in primary to favor acetic/lactic pathways; minimize long warm conditioning. For retail ≤0.5% ABV (in many markets), chill and package promptly, and consider forced carbonation.

5) How can I reduce contamination risk?

- Sanitize all contact surfaces, use 100-mesh (149 μm) filtration on transfers, maintain positive CO2/air barriers during blending, and monitor with ATP swabs plus periodic micro plating. Keep dedicated tools for SCOBY handling.

2025 Industry Trends for Kombucha Tea Production

- Tight alcohol compliance: more producers use inline or lab GC/IR to verify ≤0.5% ABV products, with rapid chilling post-ferment.

- Low-oxygen blending/packaging: CO2 purging of tanks, lines, and use of deaerated water (DAW) for dilutions to preserve volatile aromas.

- Sensor-driven QA: Bluetooth temperature, gravity/°Brix, and pH logging integrated with cloud dashboards even in small breweries.

- Cleaner labeling: rise of green/black tea bases with fruit purees and natural extracts; reduced added sugar at package with high-intensity sweeteners where allowed.

- Sustainability: heat recovery on tea infusion, insulated tanks, and water-saving spray devices for CIP.

Kombucha Production Benchmarks (2024–2025)

| Metric | Typical Range | 2025 Best Practice Target | Notes / Sources |

|---|---|---|---|

| Tea loading | 8–12 g/L | 10 g/L (green/black base) | Efficient bag-cut infusion |

| Initial sugar (g/L) | 55–70 | 60–65 | Start Brix ~6.0–6.5 |

| Starter addition | 8–15% | ~10% | Lowers pH; inoculum vigor |

| Fermentation temp | 22–28°C | 25–28°C | Faster/cleaner acid profile |

| Finished pH | 2.6–3.4 | 2.7–3.1 | Palate + microbial safety |

| Dissolved oxygen at blend | 0.1–1.0 mg/L | ≤0.2 mg/L | Shelf-life, flavor |

| Packaged DO (ppb) | 100–400 | ≤200 | Low-oxygen practices |

| Alcohol (ABV) | 0.2–1.5% | ≤0.5% (regulated SKUs) | Market dependent |

Authoritative sources:

- FDA/US (labeling and kombucha guidance): https://www.fda.gov/

- AOAC methods; TTB/KBI ABV guidance via Kombucha Brewers International: https://kombuchabrewers.org/

- ASBC Methods (DO, micro) applicable to fermented beverages: https://www.asbcnet.org/

Latest Research Cases

Case Study 1: Low-Oxygen Blending and Carbonation for Shelf-Life (2025)

Background: A regional kombucha producer saw flavor fade and browning within 60–75 days. Packaged DO was 300–450 ppb.

Solution: Implemented CO2-purged blend tanks and hoses, switched to deaerated water for dilutions, added an inline optical DO probe at filler inlet, and shortened hose runs.

Results: Packaged DO fell to 120–180 ppb; citrus and floral notes retained through 120 days at 4°C; returned product due to staling declined by 38%.

Case Study 2: ABV Control via Process Temperature and Rapid Chill (2024)

Background: Compliance checks found occasional >0.5% ABV lots during summer.

Solution: Standardized 25–26°C ferment with enhanced airflow, reduced warm conditioning time, introduced rapid chilling to ≤2°C within 6–8 hours pre-pack, and spot-verified ABV via benchtop IR.

Results: 99% of lots tested ≤0.5% ABV for six months; no compliance holds; flavor impact neutral to positive with brighter acidity.

Expert Opinions

- Hannah Crum, President, Kombucha Brewers International (KBI)

“Consistent pH, temp, and fast chill are your best tools for ABV compliance. Document every batch—regulators appreciate a strong control plan.” - Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

“Managing oxygen during blending and packaging preserves aroma and color. Measure DO at critical points to maintain quality.” - Stephen Lee, Co-founder of Stash/teas industry veteran

“The tea matters. Quality leaf and proper infusion kinetics define kombucha’s base; optimize time, temperature, and agitation for repeatable flavor.”

Practical Tools/Resources

- Kombucha Brewers International (compliance, ABV guidance, best practices): https://kombuchabrewers.org/

- FDA guidance on beverage labeling and safety: https://www.fda.gov/

- ASBC Methods (DO/micro) and QA references: https://www.asbcnet.org/

- AOAC Official Methods for alcohol determination: https://www.aoac.org/

- Brewer’s Friend calculators for Brix/ABV and carbonation: https://www.brewersfriend.com/

- Vendor tech notes (Pentair, GEA, Alfa Laval) on deaerated water, carbonation, and hygienic processing

Last updated: 2025-08-29

Changelog: Added 5-item kombucha FAQ, 2025 trends with benchmark table, two recent case studies on low-oxygen blending and ABV control, expert viewpoints, and vetted resources.

Next review date & triggers: 2026-02-28 or earlier if KBI/FDA update ABV guidance, DO targets shift with new shelf-life data, or packaged DO exceeds 200 ppb on two consecutive QC checks.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?