How to Judge the Quality of Microbrewery Equipment?

When it comes to the manufacture of beer, How to Judge the Quality of Microbrewery Equipment? there is a great deal of work that goes into it. From the equipment that is used in the manufacturing process, to the actual ingredients, many things influence the finished product.

For many people who are into beer, it is an aspiration to begin their own brewery, and create their own line of products for the marketplace.

And if there is one thing such people would like to know, it’s about trying to judge the quality of the beer making equipment. This is understandable, given the central role it plays in the beer making process.

There are several things that need to be looked into, when judging the quality of small beer equipment. Given below in the list are some of the things worth looking at.

1. The Reputation of the Manufacturer

One of the biggest factors that go into the judgment of beer equipment is the reputation of the manufacturer.

This has to do with the fact that the more reputed the manufacturer, the more likely it is that the equipment itself will be reliable. And there is a good reason for this, since the reputation itself was the result of the company providing good quality products and service over an extended period of time.

2. The Production Capacity

Another thing that has to be looked into would be the production capacity. This, in turn, will be based on the estimated production capacity of the craft brewery itself, which tends to be different from one unit to another.

Beer equipment comes in a variety of production capacities, ranging from those meant for small households to large industrial ones. This in turn means that the production capacity of the beer equipment can vary dramatically, based on the equipment being focused on.

3. Efficiency of the Equipment

Another concern that has to be addressed is with regard to the equipment efficiency. Just about any container that is airtight will do at the end of the day, when it comes to fermentation. As long as it can be sealed off from the outside world, one can make alcohol with relative ease.

But that is just one aspect of the equation. What is especially important here is that the process has to be efficient. Breweries are businesses at the end of the day, meaning that the beer manufacture process has to be done in a way that is economically viable.

What does this mean for the brewery equipment?

What it means is that in general, the equipment must remain economically efficient and viable at all times. It should permit for the alcohol formation process to take place in a way that is fast, uniform and low on maintenance.

All of these will collectively add up in the end, when it comes to the management of the company’s revenues and overall sustainability.

4. Guarantee and Warranty on the Product

Another aspect of the machine that needs to be looked into is the guarantee and warranty on the equipment.

When purchasing anything, it should be known that there is always an element of risk involved ranging from the minute to the disastrous.

This means that any beer manufacturer has to look into the reliability of the equipment being considered in terms of guarantee and warranty.

While the concept is fairly simple and easy to understand on a general level, it does vary when it comes to doing so on an industrial scale.

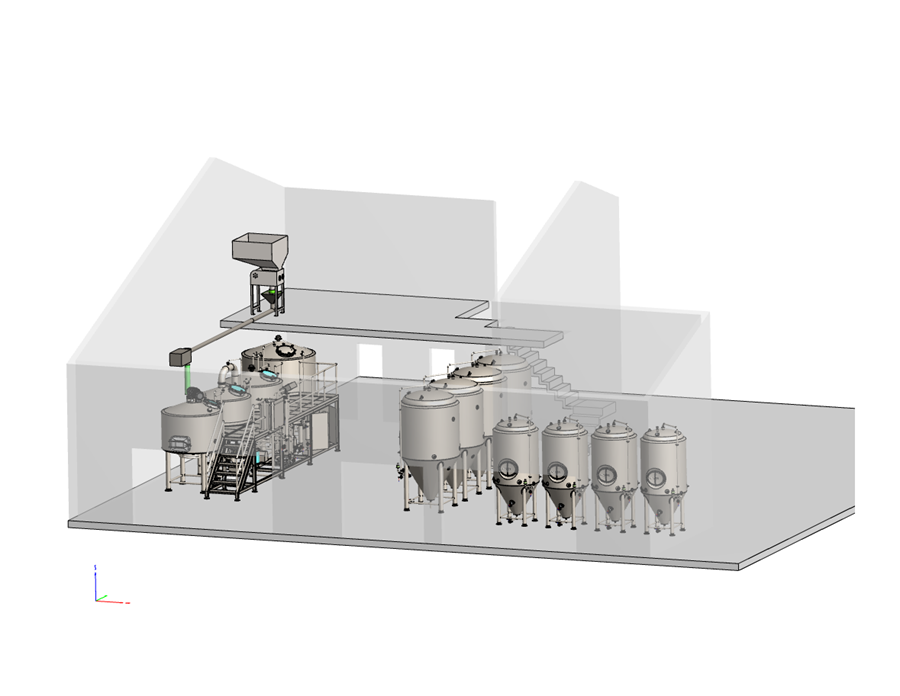

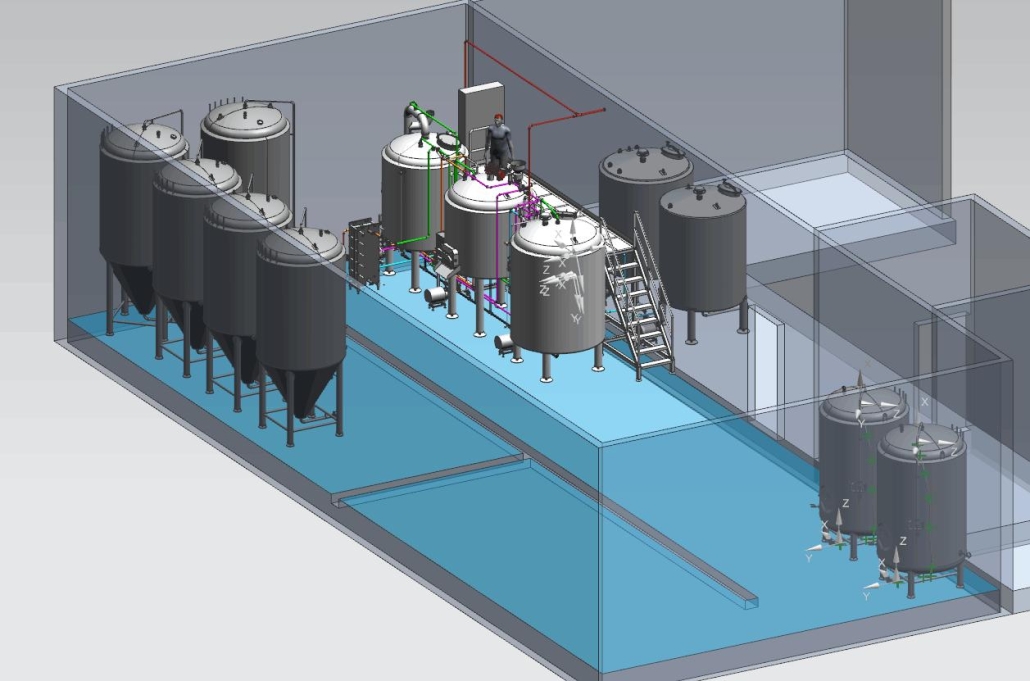

5. Efficiency of Packing & Space

One of the most important overheads that a company often deals with is that of its premises. This includes, among others, place for the factory itself, warehouses, various storage facilities, etc.

All of these things will add up to the final cost when it comes to financial viability. The reason for this is because the overheads for running a factory, is usually more than almost everything else.

Therefore, it is important that the equipment occupies as little space as possible, without compromising on the final quality of the beer. Also, this will especially be problematic when it comes to small breweries, which are limited in terms of how much money they can afford on the same.

While there is a certain limit to how much any equipment can be restricted in size, it can certainly be done in a way that works out for the owners in an economical way.

In simple words, the equipment under consideration should fit in the existing space without causing any problems.

Therefore, it is important that the equipment occupies as little space as possible, without compromising on the final quality of the beer. Also, this will especially be problematic when it comes to small breweries, which are limited in terms of how much money they can afford on the same.

While there is a certain limit to how much any equipment can be restricted in size, it can certainly be done in a way that works out for the owners in an economical way.

In simple words, the equipment under consideration should fit in the existing space without causing any problems.

6. Transporation and Logistics Costs

The fact that equipment exists and will work out for a company is great.

But at the same time, another issue that is to be addressed is that of logistics. It is true that there are many equipment suppliers available for the beer industry. At the same time however, there are a few other considerations that must be taken into account as well.

These considerations are that of logistics and transportation. For one thing, it should be known that shipping costs tend to add and often greatly increase the final bill.

Another thing to be added here is that the equipment, if being imported from another country, is often subjected to custom duties and taxes, which will once again add up to the final bill.

What this means is that the final cost of the equipment could possibly increase by several times, if these factors are taken into consideration.

Therefore, it is always a good idea to go for equipment that can be acquired in a way that is light on the wallet, but which serves the purpose without any compromise on the beer’s final quality.

- Customer Service & Aftercare

7. Customer Service & Aftercare

If there is one thing that is common for almost anything that you purchase, it is that they break down.

Things break. That’s just how everything works.

And if they do break down for whatever reason, you should be able to get the appropriate individuals who can help you in fixing the problem.

This is where things can become problematic. Getting the equipment is one thing. But it is also important that you are able to fix it whenever any problem emerges. Also, the solution for the problems should be economically viable, and shouldn’t cost a fortune for the business.

What this means is that the equipment should come with the right kind of aftercare, including, but not limited, to friendly customer service, locally available service professionals and affordable equipment service rates.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?