Choosing between All-in-one beer brewing machine and separate equipment, and the ‘Why’ behind it

Beer-making is a major industry today.

Making up a sizable chunk of the beverage economy, the industry is growing steadily all across the world. Given the trends, it is very likely that this will continue well into the distant future.

When it comes to the actual manufacture of beer, one of the most important things to consider would be that of making the beverage.

There is a lot of things to consider, when preparing that final drink, one of the most important being that of the beer making equipment.

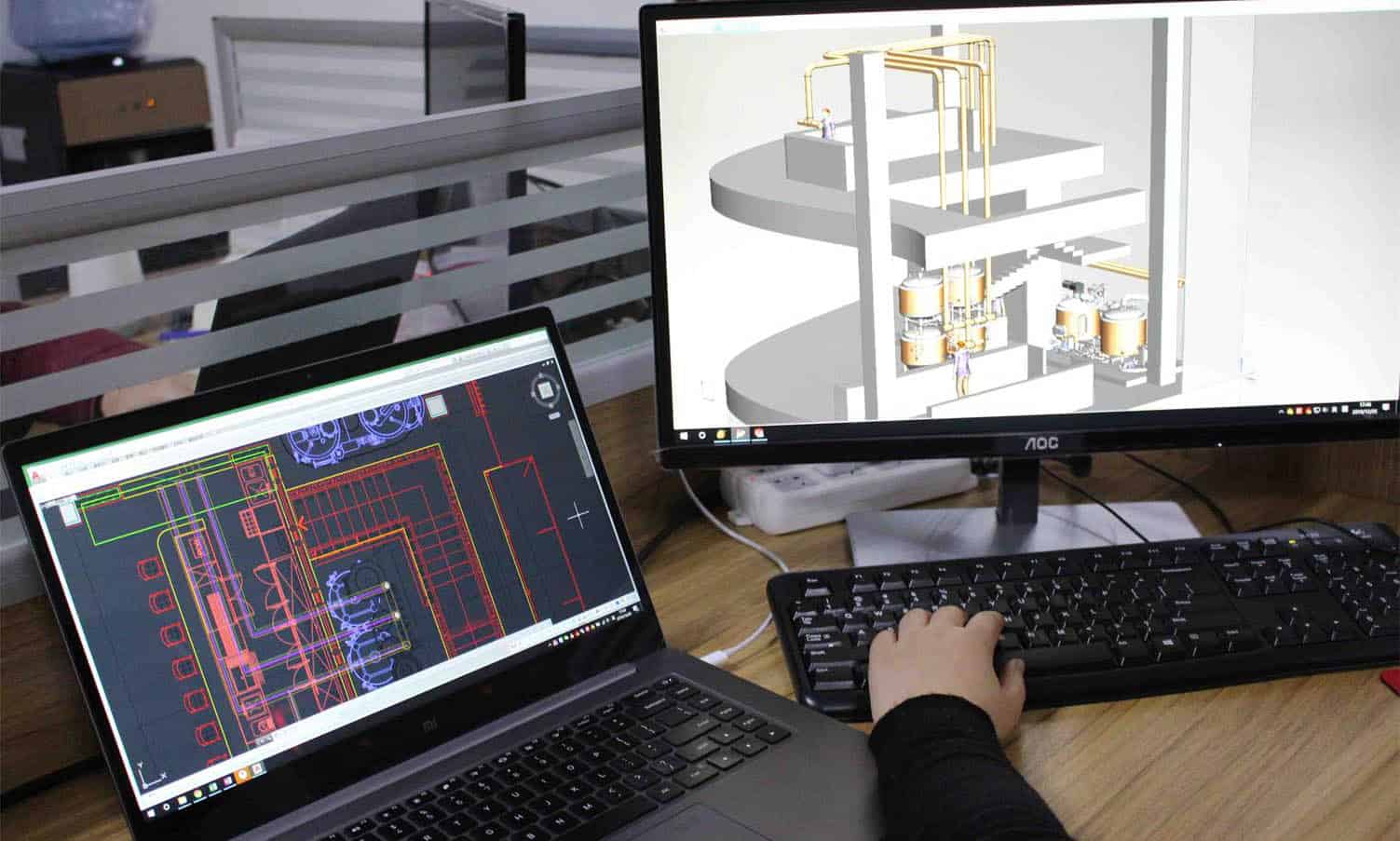

Checking out the many kinds of equipment on display, it becomes clear that there is a lot of variety to go around. Of them all, one could say that all of them can be categorized into two main types, namely, all-in-one types and the other being separate equipment.

Choosing between the two styles can prove to be rather confusing. If you’re into purchasing beer equipment, and would like to know more on the ideal one for your needs, the below sections should make it clear.

- All-In-One Beer Equipment

This is the kind of beer equipment, where, as the name would suggest, comprises of everything. From the time that the grains are introduced, to the time when the final beer is filtered out, all of it is taken care of by single equipment. There is almost no need for add-ons to a large extent, unless you are into extremely customized beers.

The usage of this kind of beer equipment is usually used in cases where the equipment is required for large batches of standardized beer. In most cases, the preparation involves manufacturing beer, whose recipes are standardized in nature. It is ideal for companies and large businesses, which are focused more on the quantity rather than quality. The main reason or this is because it is easier to buy something that is ‘plug and play’, rather than going to the trouble of assembling everything from scratch.

In addition to this, small beer companies and beer enthusiasts may also go for standardized all-in-one equipment, if they just want the beer, and wish to avoid the trouble of assembling something on their own.

Also important to add here is that the equipment is advantageous when it comes to operation and maintenance, making it ideal for brewing standardized beer in large quantities. Maintenance is a lot more efficient as there is just a single company or vendor that is needed for the service, as opposed to several companies.

Last but not the least, it can be an economic choice to buy all-in-one beer equipment in a lot of cases, which makes this a rather sound financial decision.

- Separate Equipment

This is the second category of beer equipment, and is essentially what can be described as ‘custom made’ in nature. They include machine and other equipment derived from a variety of sources, as opposed to being sold as a set by a single company.

The usage of separate equipment to manufacture beer, usually is because the beer being made is very specialized in nature. The most common reason why this is done, is because the beer being made, has a very unique, and at times patented recipes. This uniqueness of the recipe makes conventional all-in-one variety of equipment rather difficult to go for, and at times obsolete.

In the same way, everyday beer enthusiasts go for separate equipment as well, particularly in cases where experimentation is involved. This is because the specialized nature of separate equipment allows for tweaking and playing with recipes, to come up with interesting brews.

One of the main disadvantages of this is that buying separate beer equipment can be rather expensive, in certain cases. One would have to take this into consideration before going for separate equipment, as it can have a negative effect on the overall budget.

Another problem is that when several different parts are used to assemble a custom beer brewing, it may become cumbersome to deal with the operation and maintenance later on. This is because it is not always that the different parts work together in peace. Likewise, one single company or vendor may not be able to fix up the final assembly, if something should go wrong.

To sum it all up, there are indeed many more things that are taken into account, when it comes to an all-in-one beer making equipment.

The above mentioned list are but some of the key considerations, and nothing more. Your own preferences may vary, depending on the exact needs and requirements.

Additional FAQs for Choosing All‑in‑one Beer Brewing Machine vs Separate Equipment

1) What’s the realistic total cost of ownership (TCO) difference in 2025?

- All‑in‑one systems: lower upfront engineering/integration and lower routine maintenance coordination; higher replacement cost for proprietary parts. Separate systems: higher integration and installation costs; easier to replace individual components; potential savings via used market.

2) Which option scales better from pilot to production?

- Separate equipment scales more flexibly (swap/resize vessels, add automation). All‑in‑one beer brewing machines can scale via adding parallel units, but per‑unit duplication may raise CapEx per added bbl.

3) How does automation compare?

- All‑in‑one: higher built‑in automation (PID/PLC, recipe steps, alarms) out of the box. Separate: choose best‑in‑class controllers (e.g., standalone PLC, valves, sensors) and integrate; more flexible but needs engineering.

4) Which is better for low‑oxygen brewing (LOb)?

- Both can be configured for LOb. All‑in‑one machines increasingly ship with closed‑loop transfer and O2‑tight gaskets. Separate builds allow premium valves, purged manifolds, and inline DO sensors at every node, often with superior performance if designed well.

5) What are downtime and service considerations?

- All‑in‑one: single vendor service path; if the central controller fails, more of the system is down. Separate: fault isolation is easier; you can swap a pump, sensor, or valve without taking the whole brewhouse offline, provided spares are on hand.

2025 Industry Trends: All‑in‑one vs Separate Brewing Setups

- Modular automation: More vendors offer modular I/O and open protocols (OPC UA/MQTT) so both all‑in‑one and separate systems can log to cloud QA/LIMS.

- Energy and water efficiency: Heat recovery to HLT, VFD pumps, thicker insulation, and CIP optimization lower utilities 10–20%.

- LOb and shelf life: Closed transfers and inline DO checks are standardizing even in small systems, reducing packaged DO to <100 ppb (goal ≤50 ppb for hop‑forward styles).

- Financing and leasing: Increased access to small‑brewery equipment leases lowers upfront CapEx for all‑in‑one machines.

- Supply normalization: Lead times improved over 2022–2023; custom separate builds with UL/CE/CSA documentation still take longer.

2025 Comparative Benchmarks: All‑in‑one Beer Brewing Machine vs Separate Equipment

| Metric | All‑in‑one System (typical) | Separate Equipment (typical) | Notes |

|---|---|---|---|

| Upfront CapEx (3–5 bbl scale) | $25k–$85k | $35k–$110k | Spec and automation level vary |

| Install/integration time | 1–3 weeks | 3–8 weeks | Separate needs piping/controls integration |

| Automation out of box | High | Medium to custom high | Separate requires engineering |

| Expandability | Add parallel units | Add/resize vessels/components | Separate is granular |

| Utility efficiency (with heat recovery) | Good–very good | Good–excellent | Design‑dependent |

| Packaging DO with closed transfers | 30–100 ppb | 25–90 ppb | Process discipline matters more than platform |

| Lead time (standard) | 4–10 weeks | 6–16 weeks | Custom adds 4–8 weeks |

| Service model | Single vendor | Multi‑vendor | Keep critical spares either way |

Sources: Brewers Association (2024–2025) benchmarking/QA; MBAA Technical Quarterly; ASBC methods; vendor spec sheets; ProBrewer practitioner threads

Latest Research Cases

Case Study 1: All‑in‑one System Accelerates Time‑to‑First‑Sale (2025)

Background: A startup taproom needed to launch within 90 days on a tight budget and minimal technical staff.

Solution: Purchased a 3‑vessel all‑in‑one beer brewing machine with built‑in PLC, pre‑plumbed CIP, and closed‑transfer manifold; vendor provided on‑site commissioning.

Results: First legal sale at day 74; brewhouse efficiency 74–76%; packaged DO 45–80 ppb; utilities 12% lower than initial projections due to heat recovery.

Case Study 2: Separate Equipment Build Optimizes Flexibility (2024)

Background: An established brewpub wanted rapid style rotation and barrel projects without replacing the brewhouse.

Solution: Integrated separate mash/lauter, kettle/whirlpool, standalone HLT/CLT, and modular PLC with added racked manifolds and inline DO/CO2 sensors.

Results: SKU count up 40%; changeover time reduced 18%; average packaged DO 30–60 ppb; CapEx 11% higher than an all‑in‑one quote but allowed future 2x FV expansion without brewhouse replacement.

Expert Opinions

- Dr. Tom Shellhammer, Professor of Fermentation Science, Oregon State University

“For small breweries, oxygen and temperature control trump configuration. Systems that enable closed transfers and precise thermal management will protect flavor stability.” - John Mallet, Brewing Operations Consultant; author of Malt: A Practical Guide

“All‑in‑one machines are great for speed to market. If you expect frequent process changes, separate components and open‑architecture controls keep you agile.” - Annie Johnson, AHA Homebrewer of the Year; Brewing Consultant

“Budget for cleanability and ergonomics. Whether all‑in‑one or separate, validated CIP, reachable ports, and safe platforms reduce labor and contamination risk.”

Practical Tools and Resources

- Brewers Association – Small brewery QA, safety, sustainability: https://www.brewersassociation.org

- Master Brewers Association of the Americas (MBAA) – Technical papers on brewhouse design/CIP: https://www.mbaa.com

- ASBC Methods of Analysis – DO, micro, gravity, bitterness: https://www.asbcnet.org

- ProBrewer – Vendor reviews, integration tips, used equipment listings: https://www.probrewer.com

- OSHA – Brewery safety (LOTO, confined space): https://www.osha.gov

- Brewfather / Brewer’s Friend – Process logging and KPI tracking: https://brewfather.app | https://www.brewersfriend.com

Sources and further reading:

- Brewers Association 2024–2025 benchmarking and draught quality resources

- MBAA Technical Quarterly on low‑oxygen brewing, heat recovery, and CIP validation

- ASBC methods for dissolved oxygen and microbiological control

- Vendor documentation for all‑in‑one systems and modular/separate component specifications

- ProBrewer practitioner insights on cost, lead times, and serviceability trade‑offs

Last updated: 2025-09-08

Changelog: Added 5 targeted FAQs; inserted 2025 comparison/benchmarks table; provided two recent case studies contrasting all‑in‑one vs separate builds; included expert viewpoints; compiled practical tools/resources with authoritative links.

Next review date & triggers: 2026-01-15 or earlier if BA/MBAA/ASBC guidance updates, major pricing/lead‑time shifts occur, or new LOb/automation practices change platform recommendations.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?