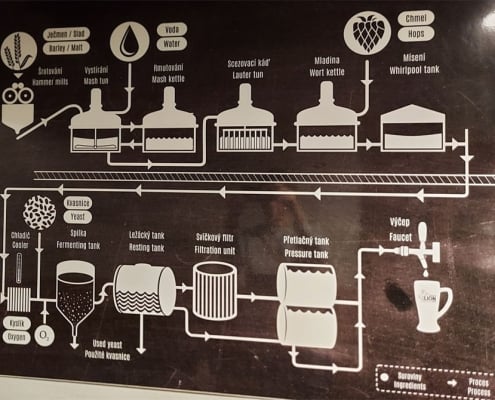

Steps of the craft beer brewing process

/Update June 13, 2022 / By YoLong brewtech

Start Today

Craft beer brewing to be part science and part art.

Craft beer has the characteristics of fine selection of materials and more flavors than traditional beer. Brewing beer with pure taste requires not only good beer raw materials but also beer equipment with excellent performance. More importantly is the formula and process, so what is the process of brewing craft beer?

Heat water and grain (and/or extract from grain), boil the mixture with hops, cool the mixture, ferment the mixture using yeast and then carbonate.

Sounds simple, doesn’t it? Today we’ll go into a depth within each step.

Malt crushing:

10 minutes before crushing, add 5% of the weight of the malt to wet the surface of the malt. When there is no obvious water droplets on the surface of the malt, it can be crushed. Well-dissolved malt can be crushed slightly smaller, but poorly-dissolved malt should be crushed finer to facilitate the action of enzymes.

Mash process:

Start stirring in the mash tun, put the crushed malt into the mash tunt, and after stirring evenly, stop the stirring, and keep it at 37°C for 20 minutes. Start stirring, turn on steam heating, heat up to 50 °C ~ 55 °C at a rate of 1~1.5 °C per minute, stop stirring, and keep at rest for 40 minutes for protein decomposition. When the rest is over, start stirring, heat the mash to 65°C, stop stirring, keep it for 70 minutes.

Heat up to kill the enzyme:

start stirring, turn on steam heating, raise the temperature to 78°C at a rate of 1~1.5°C per minute, stop stirring, keep at rest for 10 minutes, and wait for filtration.

ARE YOU HAVE BREWING QUESTIONS?

Lautering process:

start mash tun stirring, pump the wort into the lauter tank, , leave standstill for 10 to 15 minutes, and allow it to form a natural filter layer. After the static time is up, open the circulate valve, and start the lauter pump, so that the wort is recirculation in Lauter tank for 5~10 minutes. Pay attention to the backflow, and the flow rate of the pump is adjusted to 20%~30% of the maximum flow rate. After observing the clarity of the wort through the sight glass, close the valve, open the transfer valve to the kettle, and pump the wort into the kettle. The flow rate of the pump starts to be 20%~30% of the maximum flow rate. When gradually increasing the flow, the flow control should maintain a balance between the filtered wort and the wort out from the Lauter tank. After 20 minutes of lautering, samples were taken to measure the concentration of the original wort.

Boil the wort:

Open the large steam valve and start boiling. When the wort boils, start timing. The boiling time is 90 minutes, and the wort is always in the boiling state; The concentration can be appropriately extended to meet the requirements. After the wort is boiled for 5 minutes and 10 minutes before the end of boiling, add bitter and aroma hops respectively

Wort whirlpool:

After boiling, close the steam valve, open the kettle discharge valve and tangential inlet valve, and simultaneously open the wort pump, pump the wort into the whirlpool tank, and settle for 30 minutes, and then proceed to the wort cool down.

Wort cooling:

The boiled wort is pre-cooled to minus 6 degrees in an glycol water tank (ethanol and water as a mixed medium) and quickly cooled to the fermentation temperature through the heat exchanger. The fermentation temperature is different according to the yeast. The common ones are generally below 20 °C, and most of them are in the range of 9 to 15 °C.

Oxygenation of wort:

In order to avoid the oxidation of wort caused by oxygenation, oxygenation is before entering the fermentation tank after cooling to a certain temperature. Usually by wort areation set with carbon stones.

Add yeast and add wort:

Before entering the wort into the fermenter, add yeast puree, the dosage is 1% of the wort

Fermentation:

When entering the fermenter, the concentration of wort is about 9~12°P, the pre-fermentation is about 4~5 days, and the concentration of wort drops to about 4.5°P. There is no need to control the pressure in the tank. If the environment is clean, Can be fermented openly. Post-fermentation, mainly anaerobic fermentation, must keep the tank sealed, the temperature should be controlled at 12~15℃, keep the fermentation for 7~10 days, let it naturally increase the pressure to about 0.1kpa, when the post-fermentation has no obvious diacetyl taste , the fermentation is over.

End cooling:

When the fermentation is over, it should be cooled down, the speed should not be too fast, and the temperature should be lowered to about 2 °C with a gradient of about 1~0.5 °C per hour. If the cooling speed is too fast, the beer next to the jacket will easily freeze.

Maturation: Most of the yeast settles at the bottom of the tank. After removing the yeast, the resulting “tender beer” is pumped into the post-fermenter. Here, the remaining yeast and insoluble proteins are further precipitated to mature the style of the beer. The maturation time varies with the beer variety, but generally ranges from 7 to 21 days.

At this point, the brewing process is over, and the subsequent processes such as filtration, sterilization and filling are carried out according to the process requirements.

ARE YOU HAVE BREWING QUESTIONS?

BREWERY BREWING CONSULTING

From equipment costs to brewery size, construction costs and licensing, brewery operating costs can vary widely depending on your specific operation. When estimating the price of your investment, YoLong build each brewhouse on a case by case basis. The size and capacity of the brewhouse depends on what scale beer production is planned by the client. The brewhouse has different level of automatic control levels. We have Multiple types of equipment are available as well as brewery equipment financing options to help you startup and running.

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!