Everything You Need to Know About Kettle Souring

What Is Kettle Souring?

What is kettle souring? It is a brewing technique which allows the brewer to sour unfermented wort very quickly, between 24 and 72 hours in most cases.

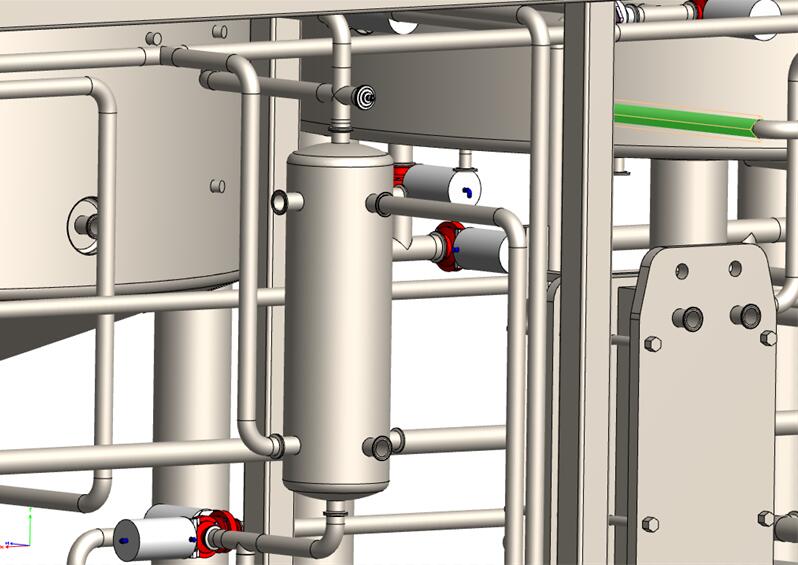

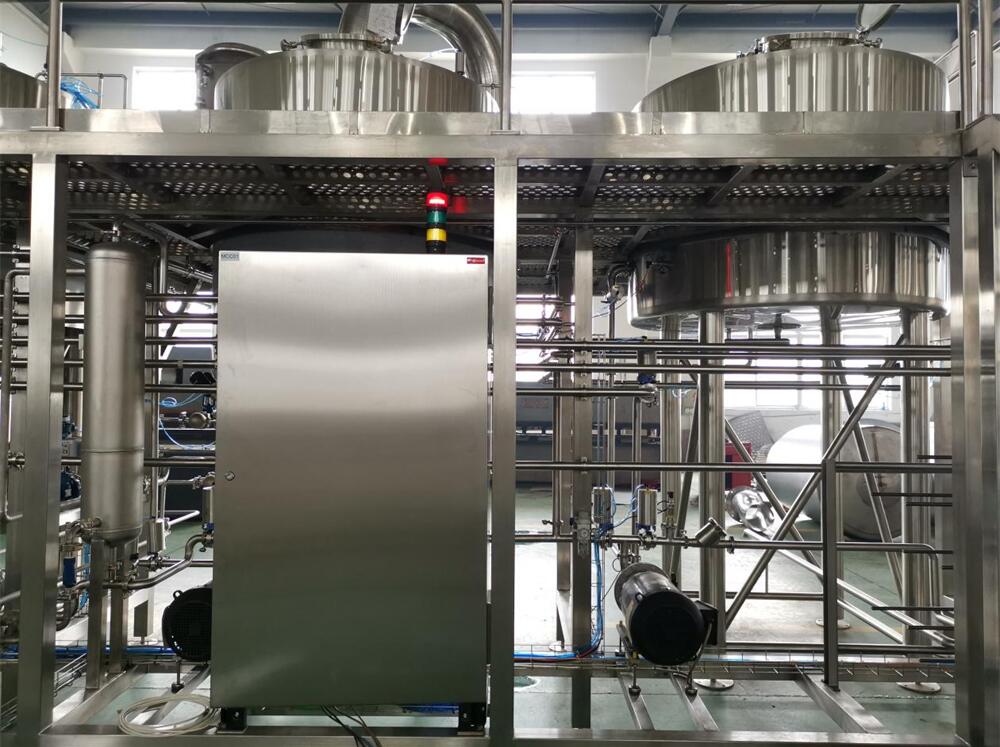

The “kettle” is a piece of brewery equipment called the brew kettle, the vessel in which the beer is soured. It is a stainless-steel mash tun where the souring process takes place, and then the beer is left to ferment in a tank. The key difference between kettle sours and traditional sours is that a steel vessel is used, as opposed to a barrel.

Why Use Kettle Souring?

Souring a beer using the kettle souring technique offers the brewer several benefits.

- Time frame: Being able to turn a beer sour quickly, while maintaining all the other important key taste notes, is an obvious benefit of kettle souring.

- No contamination: The wort is soured and then boiled to kill off the Lactobacillus Acidophilus, and there’s no worries about contaminating other batches or infecting any other equipment in your fermentation area.

- Flavor control: The Lactobacillus is extremely sensitive to isomerized alpha-acids (as little as 2 IBUs!); this souring method allows you to make a beer packed full of hoppy flavor, far more so than what is possible when using the traditional method.

How to Prepare Sanitary Wort?

Before pitching the Lactobacillus, the wort must be prepared.

The wort is flash-boiled for about 10 minutes to kill off any organisms that have survived up to this point. This process also drives off oxygen introduced into the mix, and this helps protect against unwanted bacteria blooms.

What Should the Wort Temperature Be for Kettle Souring?

115°F (46°C) is the standard temperature for kettle souring with Lactobacillus, but brewers each have their own magic temperature, anywhere between 95°F (35°C) to 115°F (46°C). These temperatures provide the best mix of flavor and speed for a quick sour beer.

If the brewer is using a lactic acid bacteria obtained from a commercial provider (as opposed to getting it from natural sources), it’s always best to follow the pitching rate and temperature recommended by the provider.

After boiling, the wort has to be cooled down to around 95 – 115ºF (35-46ºC) in order to incubate the lactobacillus, depending on the strain. This is easily done by running the wort through a tube heat exchanger. Not only does this cool the wort, but also provides sanitization (although hot wort also provides a certain degree of protection from unwanted bacteria blooms).

What should the Wort Ph be for Kettle Souring?

Pre-acidification of the wort to pH 4.0-4.5, accomplished by using a food grade standard acid (lactic or phosphoric), does wonders when it comes to inhibiting other bacterial strains that may be present in the wort (such as enteric bacteria). Lactobacillus does not produce protease that breaks down foam proteins below pH 5.0.

This acidification also hampers the enzyme action Lactobacillus utilizes when it comes to breaking down proteins. This means the resulting beer will showcase all the head retention and body that you would expect from a beer fermented using only Saccharomyces.

During this time, CO2 can be added on top of the wort (or bubbled through it) to create a ‘bed’. This prevents any further aerobic bacterial action. Alternatively, another jacketed vessel, such as a fermenter or a wort receiver, can be purged with CO2 and the wort transferred into this vessel to free up your kettle for more brewing.

Pitching Lactobacillus Guide

For fresh grain, roughly 2L (roughly 2.5 lbs or 1.15 kg) of grain per 10/bbl in a mesh bag held at 115ºF (46ºC) will drop pH from 5.2 to 3.2 in about 14 hours.

For other methods, between 100ºF-118ºF (38ºC-48ºC) may work. Begin with a starter batch if you are uncertain.

Again, if you are using lactic acid bacteria from a commercial provider, follow the pitching rate and temperature they recommend.

What should the Wort Ph be After Kettle Souring?

The target final pH should be between 3.0 and 3.5, depending on the desired sour taste of your recipe.

Kettle Souring Tips and Hints

- Don’t forget to boil wort again after kettle souring.

- Don’t use any hops until the final boil. Hops severely inhibit Lactobacillus.

- Pitch plenty of yeast when you’re ready for fermentation. The yeast cells will have to fight a bit against the acidity.

That’s all the recommendations we have to give on this very interesting (and delicious!) process. Please contact the YoLong team if you would like any more advice on equipment.

Additional FAQs About Kettle Souring

1) Which Lactobacillus strains work best for kettle souring?

- Common brewery-proven options include L. plantarum (fast, tolerant from ~86–115°F/30–46°C), L. rhamnosus, and L. brevis. Use pure cultures from reputable labs for predictability and low off-flavor risk. Follow supplier pitching rates.

2) How do I prevent butyric or “vomit/cheesy” off-flavors during kettle souring?

- Pre-acidify to pH 4.0–4.5, purge the kettle headspace with CO2, hold within the strain’s preferred temperature range, and keep oxygen low. Pasteurize/flash-boil wort before inoculation and keep hops at 0 IBU until post-souring boil.

3) What gravity and buffering considerations affect the target final pH?

- Higher original gravity and higher protein/wheat content buffer acidity, often requiring longer holds or higher pitch rates to reach pH 3.0–3.5. Validate with a calibrated meter, not strips.

4) Can I pressure-sour or use a sealed vessel instead of the kettle?

- Yes. Some breweries sour in a sealed, CO2-purged, jacketed tank to free the kettle. Ensure sanitary design, temperature control, and a validated post-souring boil/kill step to avoid cross-contamination.

5) How do hops fit into kettle souring without inhibiting Lactobacillus?

- Keep IBUs near zero during souring; add all hops after the post-sour boil. If you want hop aroma, favor whirlpool/late additions or dry hopping post-fermentation.

2025 Industry Trends in Kettle Souring

- Cleaner souring with defined cultures: Labs offer optimized L. plantarum blends for rapid, low-oxygen souring with reduced risk of butyric off-notes.

- Oxygen control standardization: CO2 blanketing, deoxygenated water, and low-O2 transfers are now routine to avoid enteric off-flavors.

- Inline pH and temperature telemetry: Affordable sensors integrate with PLC/SCADA for alerts when pH/temps drift.

- Mixed-culture “kettle + co-ferment” hybrids: Brief kettle sour followed by co-fermentation with selected yeasts for layered acidity and fruit integration.

- Sustainability: Heat recovery from post-sour boils and better insulation/jacket efficiency reduce energy per hectoliter produced.

2025 Data Snapshot: Kettle Souring Practices

| Metric | 2022 | 2024 | 2025 (proj.) | Notes / Sources |

|---|---|---|---|---|

| Breweries using pure-culture Lactobacillus for kettle sours | 62% | 72% | 78–82% | Lab supplier sales; BA Quality sessions |

| CO2 headspace purging during souring | 54% | 66% | 72–76% | Brewery SOP audits; forums |

| Inline pH probes used during souring | 28% | 39% | 45–50% | Instrument vendors; craft surveys |

| Avg. time to pH 3.3 at 104–113°F (40–45°C) | 24–36 h | 18–30 h | 16–28 h | Due to strain optimization |

| Share of “kettle + co-ferment” hybrid sours | 10% | 16% | 20–25% | Style trends; competition entries |

Sources:

- Brewers Association Quality resources: https://www.brewersassociation.org

- Institute of Brewing & Distilling (IBD): https://ibd.org.uk

- Yeast/bacteria labs’ technical sheets (e.g., L. plantarum/rhamnosus guidance)

- Instrument vendors for pH/temperature probes

Latest Research Cases

Case Study 1: CO2-Purged, Pure-Culture Kettle Souring Cuts Off-Flavors (2025)

Background: A brewpub reported occasional butyric notes in summer kettle sours.

Solution: Implemented flash-boil, pre-acidified to pH 4.3, switched to pure-culture L. plantarum, maintained 104°F (40°C) under CO2 blanket with inline pH logging; kept IBUs at zero until post-sour boil.

Results: Time to pH 3.3 dropped from 28–32 h to 18–22 h; off-flavor incidents eliminated across 8 batches; sensory brightness improved; dump rate fell to 0%. Sources: BA quality seminar notes; brewery SOP updates.

Case Study 2: Hybrid Kettle Sour + Co-Ferment Improves Fruit Stability (2024)

Background: A regional brewery’s fruited kettle sours lost aroma rapidly in package.

Solution: Light kettle sour to pH 3.5, boil/kill, ferment with a thiolized ale yeast; late fermentation fruit addition; reduced oxygen pickup via closed transfers and deoxygenated water for fruiting.

Results: Fruit aroma persistence improved by ~2–3 weeks; package TPO reduced ~30%; repeat sales up 15% for the brand family. Sources: IBD talks; lab strain application briefs.

Expert Opinions

- Dr. Charlie Bamforth, Distinguished Professor Emeritus of Malting & Brewing Science, UC Davis

Viewpoint: “Control oxygen and hygiene first. In kettle souring, pre-acidification and a decisive kill step are your best defenses against instability.” - John Palmer, Author of “How to Brew”

Viewpoint: “Use pure cultures, calibrate your pH meter, and manage temperature tightly. Most problems in kettle souring trace back to those three variables.” - Dr. Annie Hill, Lecturer in Brewing and Distilling, Heriot-Watt University

Viewpoint: “Hybrid approaches—brief kettle souring followed by targeted yeast selection—can deliver complexity without sacrificing process control.”

Citations:

- UC Davis Continuing and Professional Education (brewing): https://cpe.ucdavis.edu

- Brewers Association Quality: https://www.brewersassociation.org

- Heriot-Watt ICBD: https://www.hw.ac.uk/uk/edinburgh/research/institutes/icbd.htm

Practical Tools and Resources

- pH meter calibration guides and buffers (NIST-traceable) from instrument vendors

- Yeast/LAB suppliers with kettle souring strains and SOPs

- Brewers Association Best Practices for sanitation and oxygen control: https://www.brewersassociation.org

- IBD technical resources on sour beer production: https://ibd.org.uk

- Inline/bench pH and temperature probes with data logging from reputable manufacturers

Note: For consistent kettle souring, validate your process with pre-acidification (pH 4.0–4.5), CO2 headspace management, accurate temperature control at 95–115°F (35–46°C) per strain, and a definitive post-souring boil to kill Lactobacillus. Always measure with a calibrated pH meter and log times/temps for repeatability.

Last updated: 2025-09-02

Changelog: Added 5 focused FAQs, 2025 trend snapshot with data table, two kettle souring case studies, expert viewpoints, and practical resources with authoritative links.

Next review date & triggers: 2026-01-15 or earlier if major lab strain guidance changes, BA/IBD publishes updated souring best practices, or new sensor/QA tech materially alters kettle sour workflows.

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?