Brewpub Equipment

Brewpub equipment is ideal for restaurants and gastropubs that serve beer brewed directly on-site. Unlike large-scale bottling operations, brewpubs typically serve their beer fresh from tap kegs straight into mugs, offering customers a unique and authentic experience.

Our two-vessel brewing system comes equipped with a semi-automated control panel, providing a practical balance between manual operation and automation. When designing equipment for a brewpub setting, we prioritize cost-effectiveness—especially since many brewpubs evolve from smaller-scale homebrewing setups.

Starting any commercial brewing venture requires a careful balance of factors: investment cost, equipment size, production capacity, and ongoing maintenance. Our systems are designed to meet these needs efficiently, helping new brewpubs launch with confidence and scalability in mind.

Want to expand or build your brewery?

The sizes of our YoLong brewpub equipment starts from 5HL / BBL to 10HL / BBL. Please contact us if you need help gauging which size is most suitable for your floor space.

6HL Copper Brewhouse

6HL Copper Brewhouse 500L brewpub system

500L brewpub system 2 vessel Brewhouse-Sream

2 vessel Brewhouse-Sream 2vessel Brewing equipment

2vessel Brewing equipment 5bbl brewpub

5bbl brewpub Japan 5HL Brewhouse

Japan 5HL Brewhouse 7bbl brewpub

7bbl brewpub 7bbl brewpub system

7bbl brewpub system

Overview of the craft beer industry

The craft beer industry refers to the segment of the beer industry that focuses on small, independent, and traditional brewing methods to produce high-quality beer with unique and often experimental flavors. This industry is characterized by its creativity, innovation, and dedication to craftsmanship, as well as its focus on local communities and sustainability.

| Aspect | Craft Breweries | Commercial Breweries |

|---|---|---|

| Scale | Small-scale, often locally operated | Large-scale, regional or international operations |

| Ownership | Independently owned, often by passionate brewers or local entrepreneurs | Typically owned by large corporations or conglomerates |

| Brewing Methods | Traditional methods, often with hands-on craftsmanship | Highly automated, mass production techniques |

| Ingredients | Focus on high-quality ingredients and unique recipes | Emphasis on cost-efficiency and standardized ingredients |

| Flavor Profile | Diverse and experimental flavors (e.g., IPAs, stouts, sours) | Consistent, mainstream flavors designed for mass appeal |

| Innovation | Highly creative, frequently releasing new styles and limited editions | More conservative, centered on core flagship products |

| Market Focus | Community-focused, building local brand identity and loyalty | Broad consumer base, heavily reliant on large-scale branding |

| Sustainability & Community | Often emphasize environmental practices and community involvement | Primarily focused on market share and profitability |

| Growth Trend | Rapidly growing, especially among younger and niche consumers | Slower growth, facing pressure from craft beer competition |

| Challenges | Fierce competition, regulatory complexity, balancing consistency with innovation | Maintaining brand relevance and adapting to changing consumer preferences |

If you’re preferred for one of our YoLong specialists to work out the estimate for you, please contact us.

Brewpub equipment upgrades can include commercial brewery sizes, depending on the above mentioned needs. But developing a brewpub with commercially accessible features is different from a straight-up commercial business development.

YoLong brewpub upgrade Solution

Starting a brewpub business – and tailoring the equipment that is already available to meet your higher capacity needs – means that we don’t need to keep the old capacity in order to produce a higher volume of products with the previous system design, especially if the first brewpub iteration still has viable (reusable) equipment, such as a semi-auto control level, gas / electrical heating option, integrated control cabinet, Uni-tanks, etc. Doing this is what lowers the cost of a new brewpub considerably.

Here are some of the ways a YoLong brewpub upgrade can save you time and money.

Brewhouse

Fermentation

Auxiliary equipment

And as with any project and upgrade, the more equipment you can keep from the old set up, the more you’ll save in costs.

Before a new setup project is started, the quality of the old brewpub equipment must be thoroughly reviewed. It is essential you choose a qualified supplier to review your old equipment to make sure it is suitable for the new setup, or else you might be replacing perfectly good brewing equipment.

We can help you with the following brewery equipment orders and installations so that you get the tank brewery and electric brewing supplies you need:

Examples of Brewpub Brewing Equipment

6HL 2 Vessels Electric Copper Brewing System

10HL 3 Vessels Steam Heating Brewing System

12HL 3 Vessels Steam Brewing System

Key Benefits of Brewpub Equipment

Brewpubs, which are typically small bars that brew their own beer, often purchase craft beer equipment to produce their own unique beers. Through the process of brewing their own beer, brewpubs can enjoy the following benefits:

Uniqueness and distinctiveness

Brewing their own beer allows brewpubs to offer customers unique flavors and styles, which can help attract more customers and increase brand awareness.

Higher profit margins

The cost of brewing beer is typically lower than purchasing finished beer, allowing brewpubs to achieve higher profit margins when selling their own beer.

Flexibility and innovation

Brewing their own beer allows brewpubs to experiment with different ingredients and brewing methods, creating unique beer flavors. Additionally, brewpubs can adjust their beer offerings based on seasonal and market demands.

Increased customer engagement

Brewing their own beer can attract customers to visit and learn about the brewing process, increasing customer loyalty and satisfaction.

Environmental sustainability

Brewing their own beer can reduce carbon emissions and energy consumption from transporting finished beer, promoting environmental awareness and sustainability.

Support for local economies

Brewing their own beer can support local farmers and suppliers, helping to drive local economic development.

In summary, purchasing craft beer equipment to brew their own beer can provide brewpubs with unique flavors and experiences for customers, increase profit margins, enhance flexibility and innovation, support local economies and promote environmental sustainability. These benefits can help brewpubs stand out in a highly competitive market.

10 pain points when purchasing brewpub equipment

10 Yolong solutions for brewpub equipment

By offering these solutions, Yolong can effectively meet the challenges that customers face when purchasing Brewpub equipment.

Advantages of a Turnkey Brewpub & Restaurant Brewery Project with YoLong

01. Professional Brewpub Design

YoLong designs and installations save on space and costs. Every YoLong brewhouse is set up on skids, as this compact design works best with the dimensions of every brewpub establishment, as well as making the health and safety aspect of cleaning much easier.

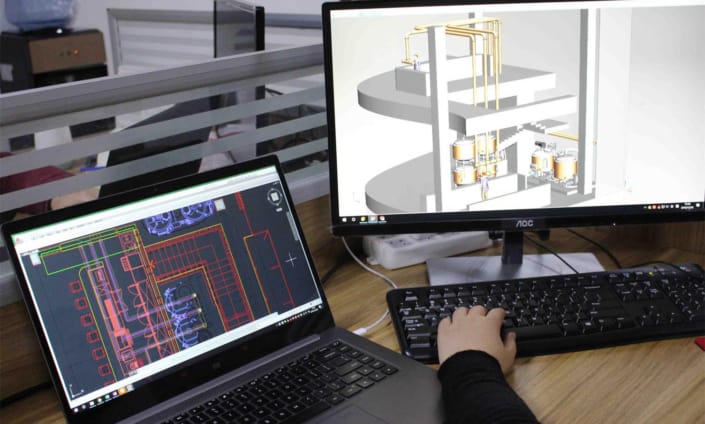

For each one of our brewpub / restaurant brewhouse layouts, YoLong custom-creates a 3D model design using state of the art Solidworks and CAD. This brewpub layout technique ensures every detail – from malt handling to beer tapping to piping – is laid out for maximum use of space and productivity: the perfect blend of aesthetics, functionality, and machinery.

02. Brewpub Project Turnkey Finish

At YoLong, we focus on the finish product and details during every step of the fabrication process. We have a rich tradition of presenting the final product on time, ready to begin production, and perfectly polished. We bring this experience and expertise to every brewpub project we undertake.

YoLong Quality: The standard of vessels is inside 2B, Ra≤0.6 and external #4 or copper finish.

03. Control Cabinets for Brewpub Automation

When you have your brewpub on full display to the customers on your premises, the last thing you want to be doing is manually operating every stage of your own brewery setup. Ask any homebrewer, and they will tell you that being involved in the brewery process is hard work. Therefore, YoLong offer two control system options for brewpubs and restaurants: semi-automatic or fully automatic control.

04. Commissioned & Checked Before Shipment

Every brewhouse undergoes full processing and commissioning at the YoLong facility before shipment commences. We test temperature control status, piping work, programming in PLC, material flow, etc. in accordance with the YoLong promise and guarantee for a fully functional and successful brewing experience. Our customers get a complete turnkey service.

How To Calculate Brewpub Equipment Cost?

Brewpub Project Turnkey Finish

At YoLong, we focus on the finished product, high quality functionality and details during every step of the fabrication process. We have a rich tradition of presenting the final product on time, ready to begin production, and perfectly polished. We bring this experience and expertise to every brewpub project we undertake.

YoLong Quality: The standard of vessels is inside 2B, Ra≤0.6 and external #4 or copper finish.

Control Cabinets for Brewpub Automation

When you have your brewpub on full display to the customers on your premises, the last thing you want to be doing is manually operating every stage of your own brewery setup. Ask any homebrewer, and they will tell you that being involved in the brewery process is hard work. This is why YoLong offers two types of control system options for brewpubs and restaurants: semi-automatic or fully automatic control.

Commissioned & Checked Before Shipment

Every brewhouse undergoes full processing and commissioning at the YoLong facility before shipment commences. We test temperature control status, piping work, programming in PLC, material flow, etc. in accordance with the YoLong promise and guarantee for a fully functional and successful brewing experience. Our customers get a complete turnkey service. If you are interested in our hands-on installation service, we can also arrange for a trusted member of our professional team to come and assist you getting started.

Regarding the setup of pub brewing or restaurant brewing establishments, the design is completely different from that of microbreweries. Brewpub establishment owners want to have their brewing area aesthetically beautiful to catch the eye, but also with a larger output.

The configuration of the brewpub is completely different from commercial scale breweries; a brewpub is often the beginning stage of a larger business offering commercially sold beer. This will require brewpub equipment to be adaptable in order to maximize the profits based on the specified budget and expansion plans.

For any brewpub brewery configuration – and taking the quality of the brew and the reliability of the equipment into account as well – higher automation might be needed to control the brewing process and manage the operation’s costs effectively.

From a brewpub or restaurant customers’ point of view, they want to eat and drink in a place where the production of beer entertains them, but also doesn’t intrude upon their meal. It must also be a beautiful setup to look at or else the customers might not want to drink the beer!

So, based on all of the above criteria, it’s safe to say that the design, layout, and configuration of brewing equipment for a brewpub or restaurant must consider the following:

Aesthetics | Utilization of space | Safety | Easier Operation | Cost effectiveness | Expansion possibilities