When it comes to selecting the right brewing equipment manufacturer, it’s essential to evaluate the company’s offerings, reputation, and commitment to quality. Yolong Brewtech, a China-based company specializing in brewing equipment, has several compelling reasons to be considered for your brewing equipment needs. Here are some key factors that set Yolong Brewtech apart:

Customized Solutions: Yolong Brewtech is committed to providing tailored solutions to meet the specific requirements of their clients. They offer customizable brewing equipment, including brewhouses, fermentation tanks, and other essential components, ensuring that your brewing setup is perfectly suited to your needs and preferences.

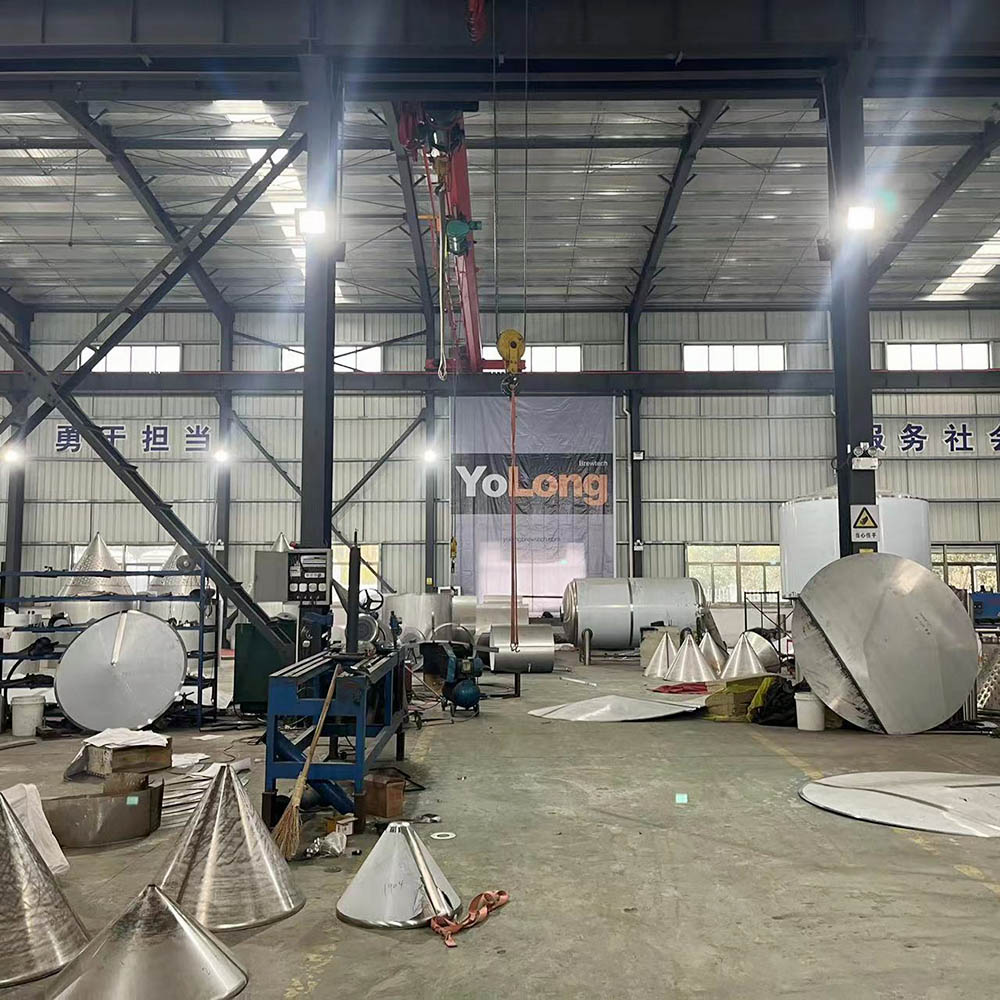

High-Quality Manufacturing: Yolong Brewtech emphasizes the use of high-quality materials and precision engineering in the manufacturing process. Their brewing equipment is designed and built with durability, efficiency, and performance in mind, ensuring that your investment will stand the test of time.

Innovation and Technology: Yolong Brewtech is dedicated to incorporating the latest innovations and technological advancements into their brewing equipment. They constantly research and develop new solutions to improve their products, ensuring that you have access to state-of-the-art brewing systems.

Comprehensive Services: Yolong Brewtech provides a full range of services, from equipment design and manufacturing to installation and after-sales support. They work closely with their clients throughout the entire process, offering expert guidance and support to ensure a smooth and successful brewing experience.

Global Reach: Yolong Brewtech has an extensive global presence, having supplied brewing equipment to clients in over 50 countries. Their international experience allows them to understand and cater to the unique needs and preferences of brewers worldwide.

Competitive Pricing: Despite the high quality and customization options offered by Yolong Brewtech, their pricing remains competitive within the market. This makes their brewing equipment an excellent value for those seeking a balance between quality and affordability.

Conclusion: Choosing Yolong Brewtech for your brewing equipment needs offers several advantages, such as customized solutions, high-quality manufacturing, innovative technology, comprehensive services, global reach, and competitive pricing. By considering these factors, you can make a well-informed decision and invest in brewing equipment that meets your specific needs and requirements.