Product categories

- MALT TECHNOLOGY (1)

- BREWERY TANK (8)

- BREWING SYSTEM (6)

- HOP TECHNOLOGY (2)

- YEAST TECHNOLOGY (2)

- SS TANK (5)

- CONTROL SYSTEM (2)

- PROCESS SYSTEMS (1)

- PACKAGE MACHINE (1)

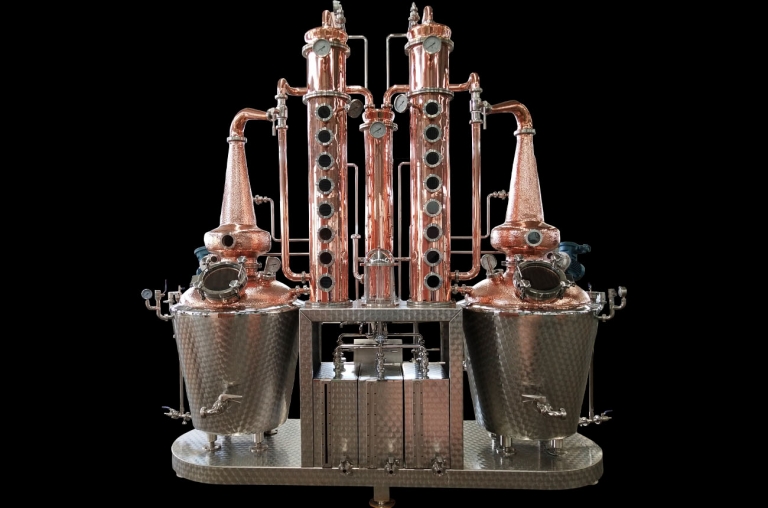

SS Tank

“SS tank” stands for “stainless steel tank.” Stainless steel tanks are commonly used in the brewing, food and beverage, and pharmaceutical industries for storing and processing liquids, such as water, wort, beer, and other beverages.

Stainless steel tanks are preferred in these industries due to their durability, corrosion resistance, and ease of cleaning. They are available in various sizes and configurations to meet the specific needs of different applications, and can be customized with features such as insulation, agitators, and temperature control systems.

A Step-by-Step Guide to the Beer Manufacturing Process

Fermentation Controller:Uses, Types, and Buying Guide

About Yolong

Founded in 2004 – With over 15 years’ experience in the brewery equipment manufacturing business – YoLong Brewtech has set the standard for fabricating custom-designed and pre-made brewing equipment at the highest levels of value and quality. Our dedicated and experienced team has helped us become an industry leader in manufacturing products for one of the most fast-growing industry sectors in the world: Beverages; Beer; Cold Brewed Coffee; Kombucha; Infused Teas; Wine.

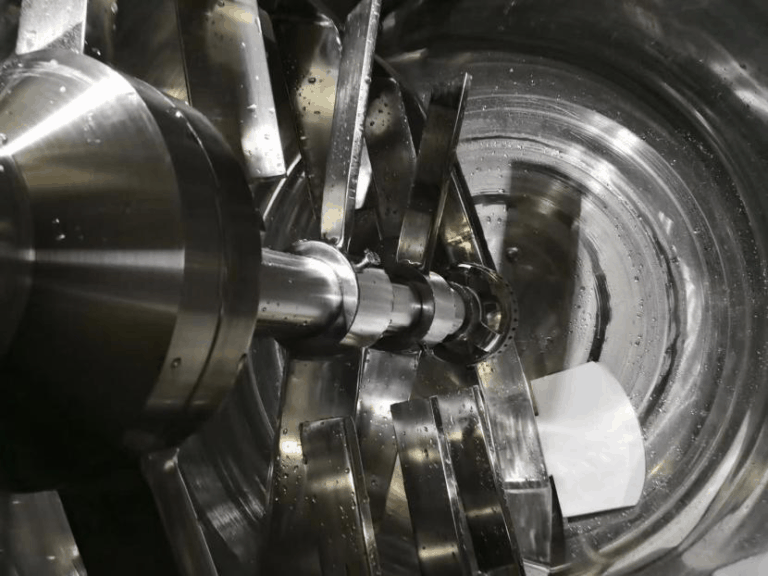

YoLong Brewtech’s staff work together in our state-of-the-art 36,000 m2 / 3350 ft2 manufacturing plant in the Ningbo City Economic Development Zone, China. We ensure every custom-designed project is fabricated to our customer’s exact specifications. The YoLong manufacturing plant is able to meet virtually any specification a customer requires.

Our Factory Gallery

Why Choose Us

Yolong come to the table not only as a craft beer equipment solution provider, but also a partner. We’re always combining our business acumen and entrepreneurial vision with amazing craft beer equipment manufacturing expertise and the ability to execute quickly and efficiently, taking your idea to market under fast-response.

“We focus our capabilities on providing one-stop services. You will find us very eager to know about your need, so to offer you the best solution. “

Alan – Founder

200+

Project Completed

500+

Satisfied Clients

150+

Expert Teams

50+

Win Awards

We Own Factory

We have our own factory since established, which means there is no trader between us, which means that we can achieve the most satisfactory level in terms of price, MOQ and product services.

Reasonable Price

We are a factory, not a trading company, and the relationship between you and me is direct, which saves both money and hassle. The direct production process reduces costs, so we can give you very competitive prices.

Unmatched

Service.

Unmatched

excellent.

One-Stop

Most factory products cannot meet the demand of product diversity, but we have a multitude of craft beer equipment products to choose from. We offer a truly one-stop service. Yolong have years of knowledge in this industry, and are willing to guide you along your way.

Common Vision

Yolong are not like the traditional supplier in China that you might be used to. We are a supplier that understands our customer’s needs, as well as global market trends. We aim to provide unmatchable product and customer service to our clients, while constantly pursuing innovation in our products.

Good Service

Most factories primarily focus only on manufacturing, which leads to a lacking of sales and service awareness. Yolong have our own sales team, technicians and after-sales staff, which means that not only can we provide faster and better-quality service.

© Copyright – Yolong Brewtech